Grain steaming process for liquor brewing

A technology of steaming grain and craftsmanship, which is applied in the field of wine making, can solve the problem that steamed grain is not easy to flower, and achieve the effect of full grain, saving time and uniform flowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

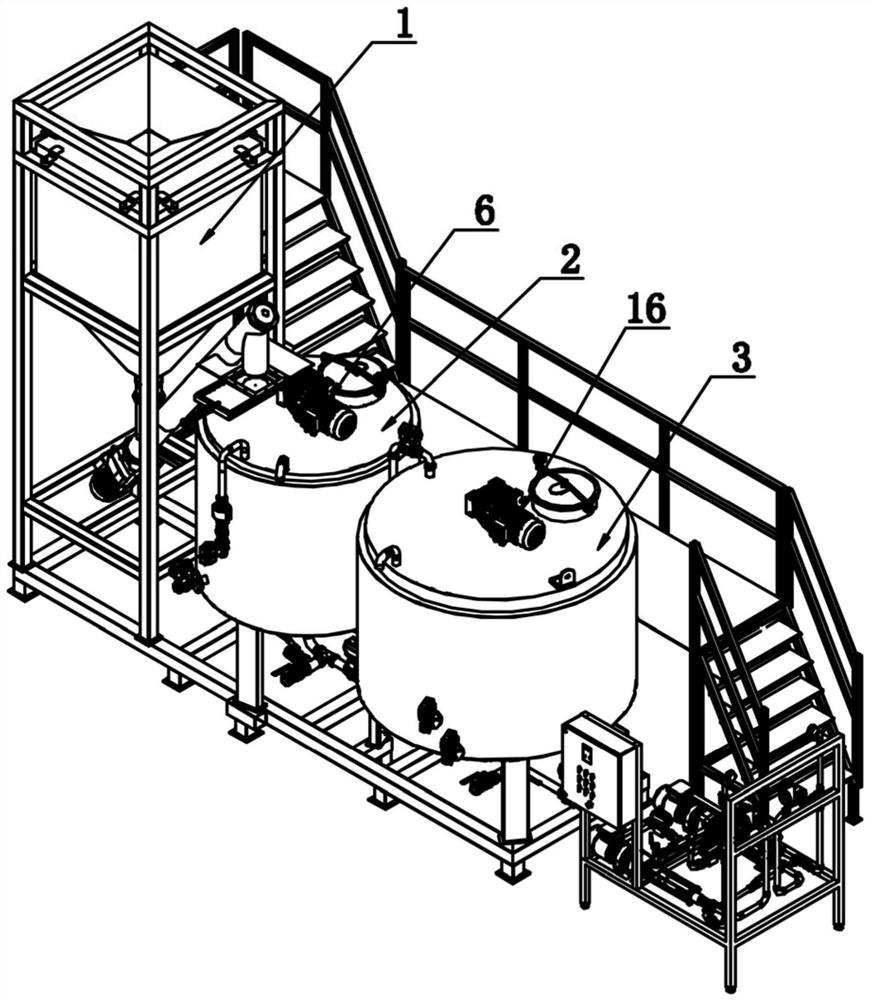

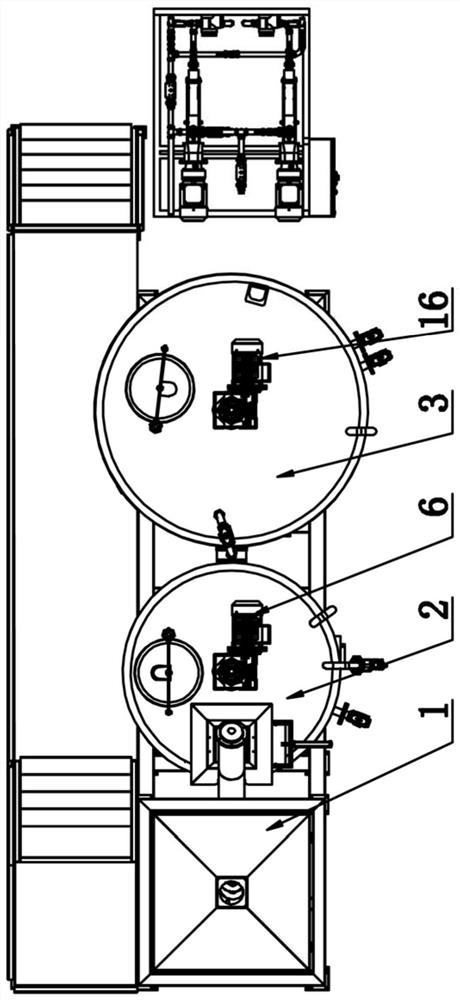

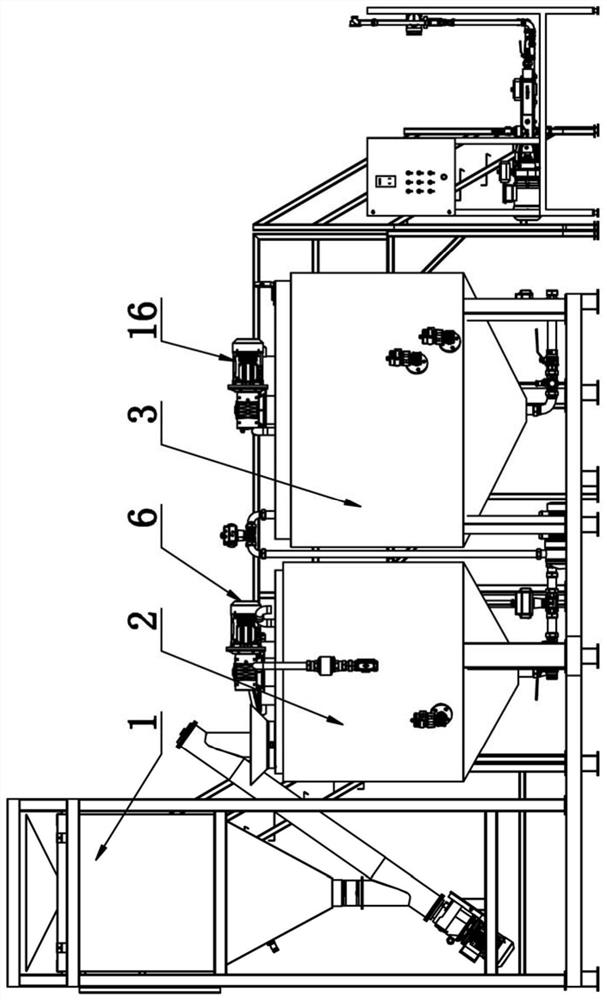

[0047] Such as Figure 1-10 Shown, a kind of steamed grain process for brewing, comprises the following steps:

[0048] step a preparation

[0049] Put the grain into the grain supply bin 1 of the grain steaming equipment;

[0050] Step b soaking grain

[0051] The grain is transported from the grain supply bin 1 of the steaming grain equipment to the pretreatment bin 2 of the steaming grain equipment, and the pretreatment bin 2 is filled with hot water until the hot water is submerged in the grain in the pretreatment bin 2, and the soaking time is not less than 10 Hour;

[0052] step c cleaning

[0053] Drain the hot water in the pretreatment bin 2, and fill it with clean water, stir and clean the grain in the pretreatment bin 2 of the grain steaming equipment, then discharge the cleaned water, pour clean water again, and discharge after agitation until the washed water is discharged no turbidity;

[0054] step d cooking

[0055] Fill clear water in the pretreatment ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com