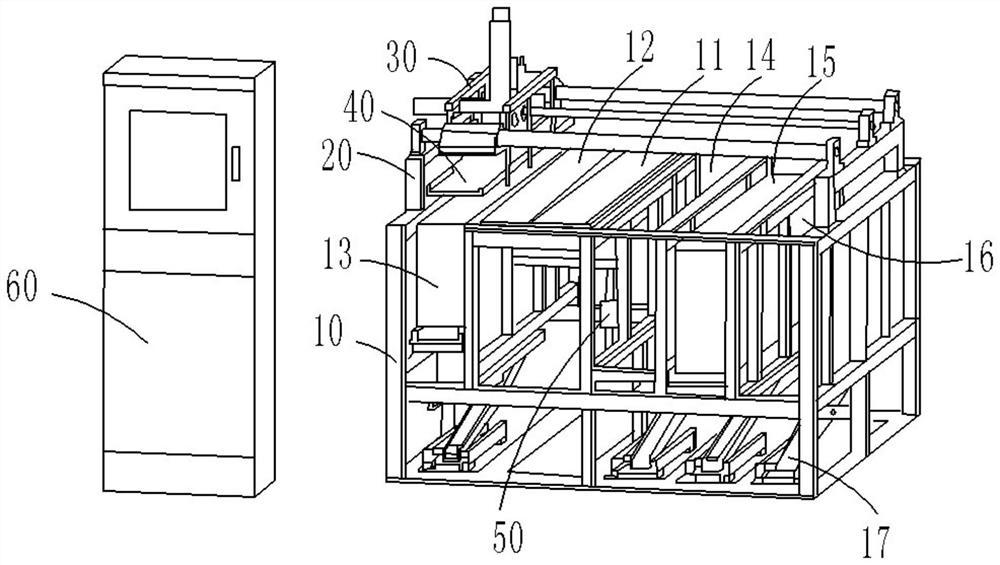

Graphite boat card point automatic loading and unloading device

An automatic loading and unloading, graphite boat technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve problems such as complicated steps, slow production progress, stuck point damage assembly, etc., to improve product qualification rate, Improve the degree of automation and realize the effect of automatic positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The working principle of the present invention:

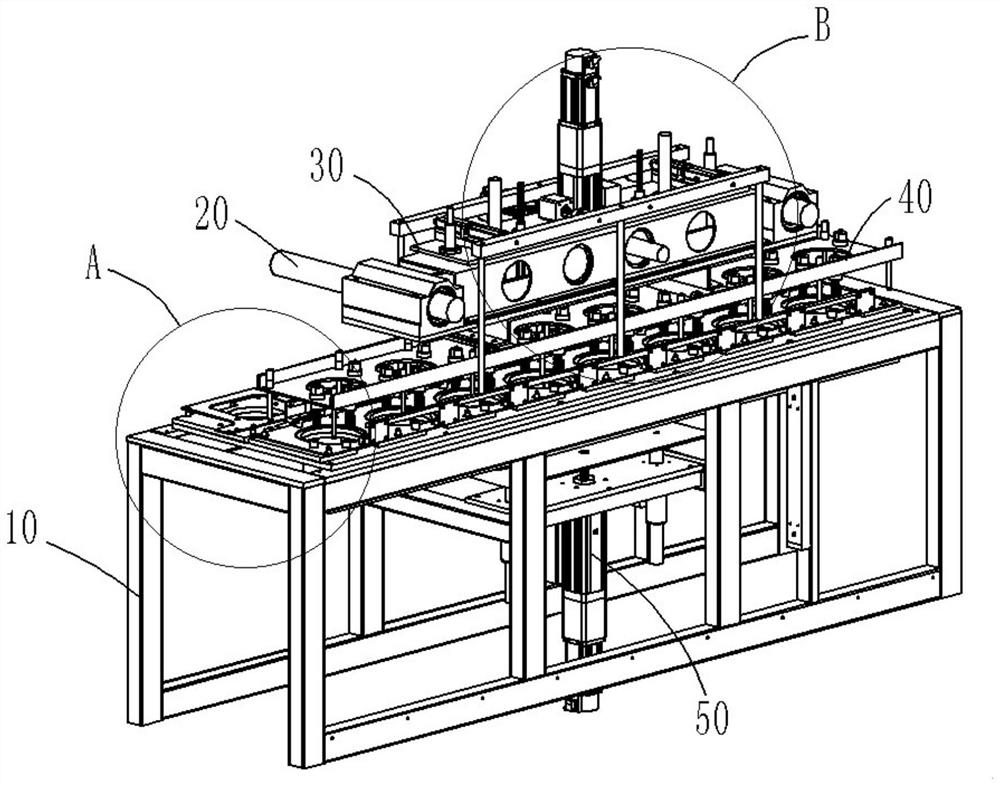

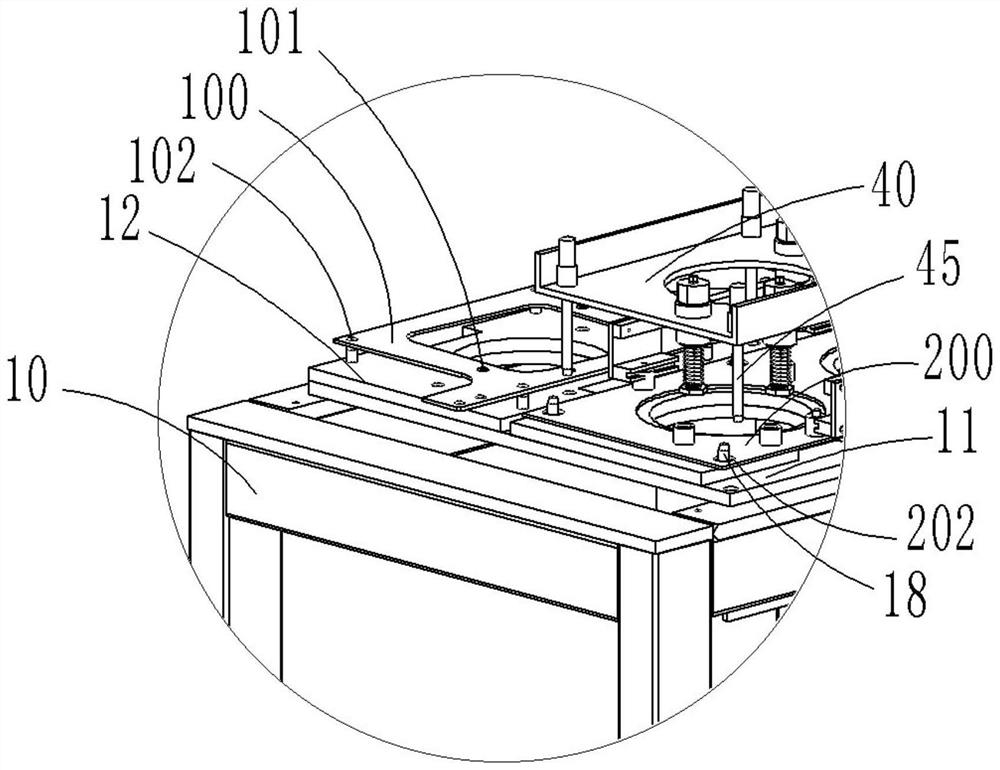

[0056] The new card point is loaded into the card point sleeve 201 of the empty card point template, and the card point sleeve 201 is loaded into the card point template 200 . There are 29 pieces of graphite boat sheet 100 in total, corresponding to 29 pieces of clamping point template 200 . The lifting adjusting device 17 located at the bottom of the graphite sheet to be loaded and unloaded card position 13, the loaded graphite sheet position 14, the card point template position 15 and the empty card point template position 16 adjusts the placement plate 171 to a predetermined position, which is convenient for grasping the mold. A group of 30 pairs grabs and puts down the graphite boat piece 100 and the clamping point template 200 .

[0057] The moving screw 23 is driven to rotate by the driving device 25 on the moving frame 21, and the moving frame 21 is driven to slide along the moving screw 23 and the guiding optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com