Asphalt mixture compaction process and pavement construction method

A technology of asphalt mixture and construction method, which is applied in the direction of roads, roads, road repairs, etc., and can solve problems that affect the service life of the road surface, road surface cracks, and affect the quality of road surface construction, and achieve the effect of improving the compactness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

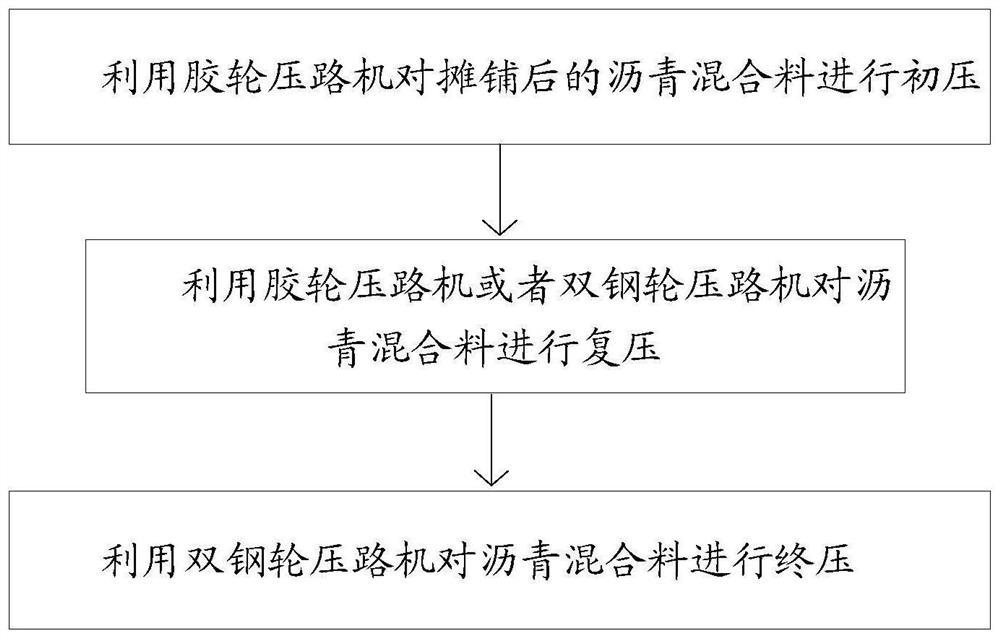

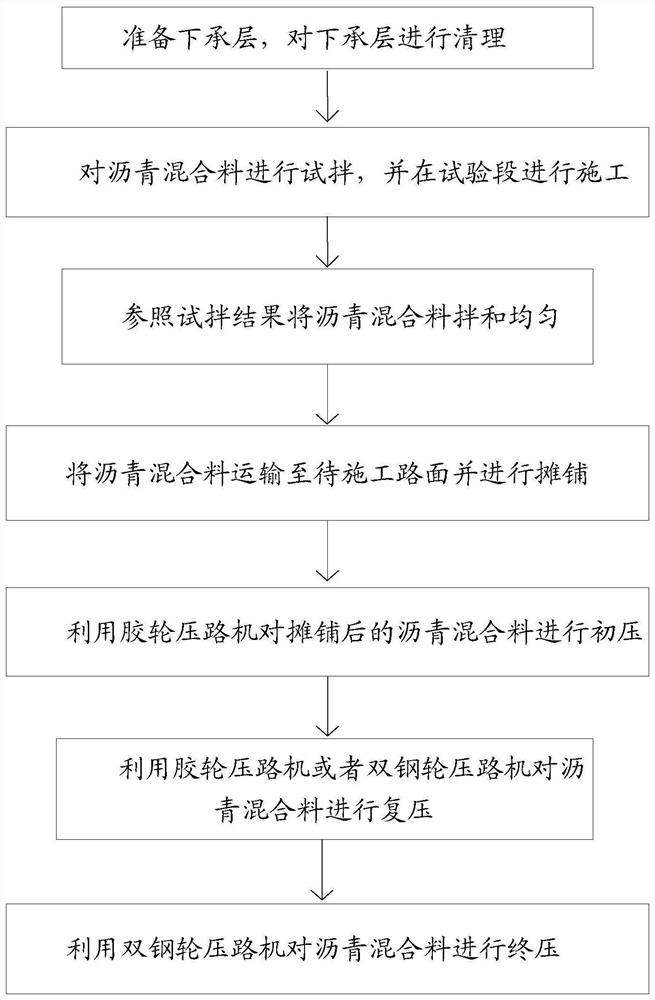

[0030] figure 1 The block diagram of the steps of the asphalt mixture compaction process that the embodiment of the present invention provides; figure 1 Shown, the asphalt mixture compaction technology provided by the invention comprises the following steps:

[0031] Initially press the paved asphalt mixture with a rubber-tyred road roller;

[0032] Recompact the asphalt mixture with a rubber-tyred roller or a double-steel roller;

[0033] Final compaction of the asphalt mixture with a tandem roller.

[0034] Further, before the step of rolling the paved asphalt mixture with a rubber-tyred roller, it also includes: coating the tires of the rubber-tyred roller with an anti-adhesive agent.

[0035] Wherein, the anti-adhesive agent is an oil-water mixture, a mixture of vegetable oil and water can be selected, and diesel oil is avoided for mixing.

[0036] Specifically, before the rubber-tyred road roller rolls, the anti-adhesive agent is sprayed on the waterproof cloth laid o...

Embodiment 2

[0052]On the basis of the above embodiments, further, the present invention also provides a pavement construction method, including the asphalt mixture compaction process provided in Embodiment 1. During use, the rubber-tyred roller can change the inflation pressure according to the actual demand to change the ground pressure, that is, the pressure of the rubber-tyred roller on the asphalt mixture can be greater than that of the double-steel roller on the asphalt mixture. In addition, during the compaction process, the rubber-wheeled road roller can carry out kneading and pressing, that is, it has a kneading effect, so that the particles of the compacted layer can be fitted with each other without being damaged, and the compacted layer can be evenly compacted. Then, the asphalt mixture is re-pressed with a rubber-tyred roller or a double-bar roller, and finally the asphalt mixture is finally compacted with a double-steel roller, and the compaction steps are repeated to further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com