Tungsten oxide-graphene photochromic composite film and preparation and application methods thereof

A technology of graphene composite and composite film, which is applied in the direction of optics, optical components, instruments, etc., can solve the problems of poor performance, long photochromic fading time, etc., to improve uniformity and compactness, improve photochromic performance, Apply promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

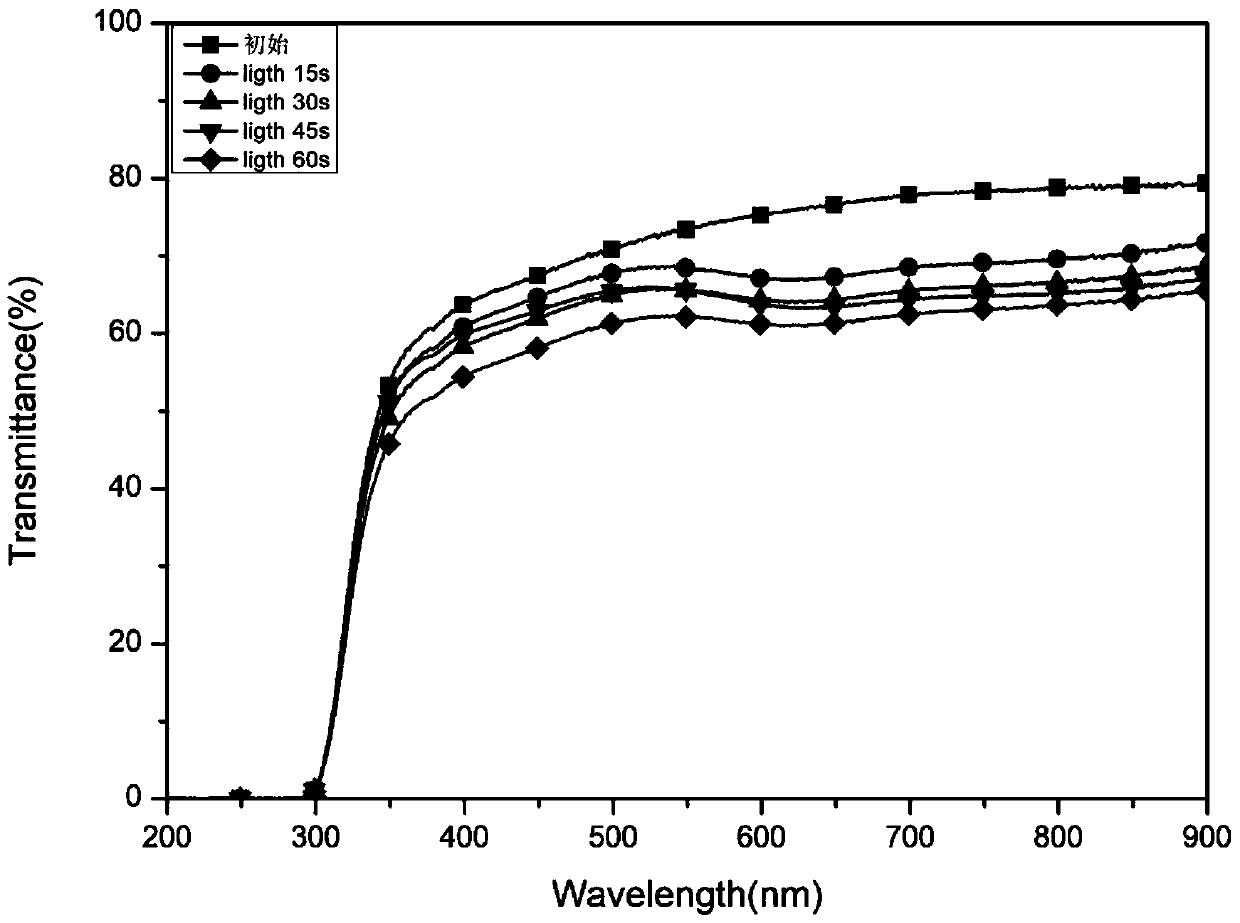

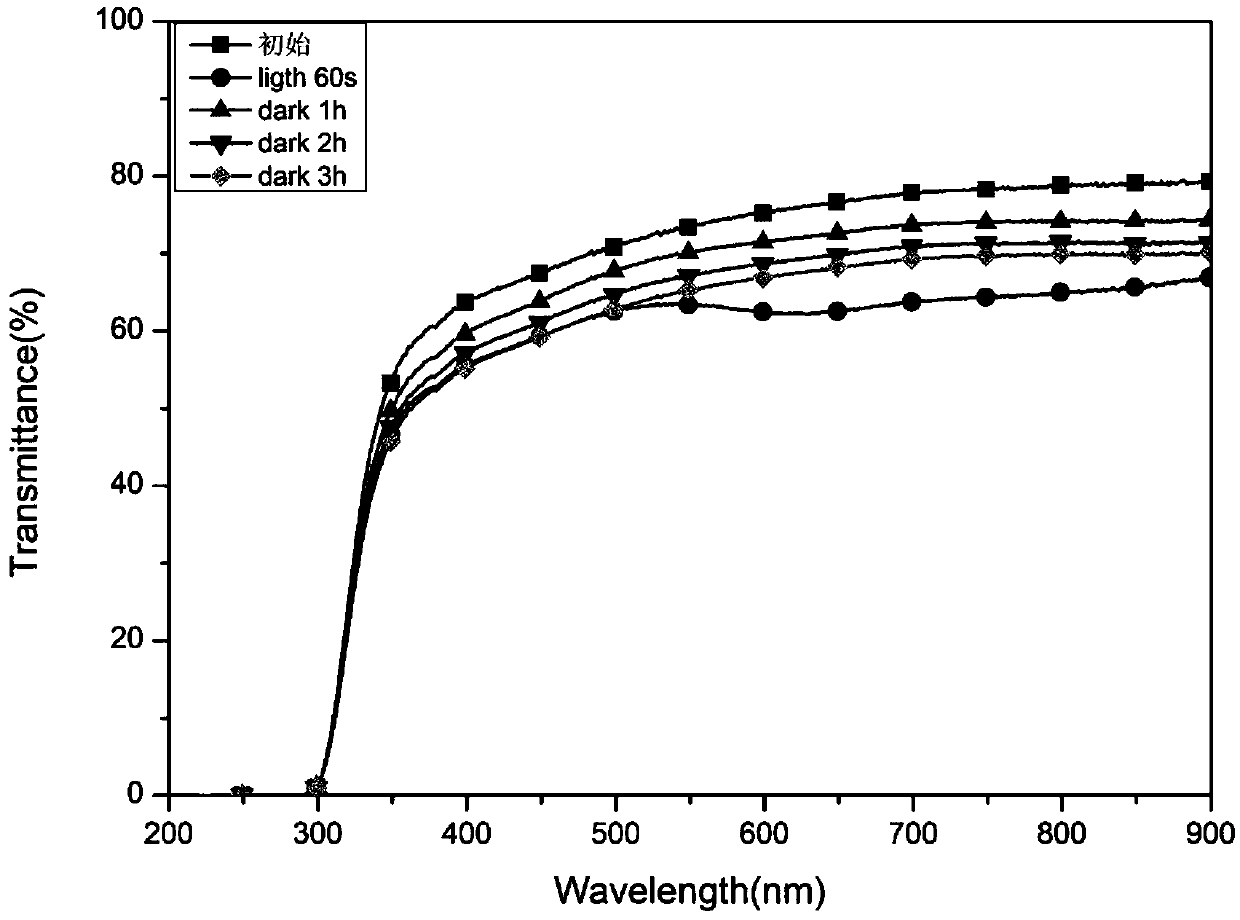

[0030] The parameters of the tungsten oxide-graphene composite film prepared by dipping and pulling method are the same as those of the comparative example. Weigh 6.6g of sodium tungstate and dissolve it in 20mL of ultrapure water, and add concentrated hydrochloric acid dropwise during stirring to adjust the pH to 4 to obtain 0.4mol / L sodium tungstate solution A. Weigh 1.8g of oxalic acid and dissolve it in 20mL of ultrapure water, and ultrasonically shake at 50°C for 10min to prepare 0.7mol / L oxalic acid solution B. Weigh 1.26 g of citric acid and dissolve it in 10 mL of ultrapure water to prepare citric acid solution C with a concentration of 0.6 mol / L. Mix and stir solution A and solution B for 10 minutes, then add solution C, continue stirring for another 10 minutes, and age in air for 24 hours after stirring to obtain WO 3Precursor sol. in WO 3 Hydroxylated graphene quantum dots were added to the precursor sol at a concentration of 0.14g / L and ultrasonically oscillated...

Embodiment 2

[0033] Preparation of WO by spin coating method 3 -The parameters of the graphene composite film are the same as those of the comparative example. Weigh 8.63g of calcium tungstate, dissolve it in 20mL of ethanol, and add concentrated sulfuric acid dropwise during stirring to adjust the pH to 3 to prepare 1.5mol / L calcium tungstate solution A. Weigh 1.8 g of oxalic acid, dissolve it in 20 mL of ultrapure water, and oscillate ultrasonically at 50 °C for 10 min to prepare 0.7 mol / L oxalic acid solution B. Weigh 0.84 g of citric acid and dissolve it in 10 mL of ultrapure water to prepare 0.4 mol / L citric acid solution C. Mix and stir solution A and solution B for 10 minutes, then add solution C, continue stirring for 10 minutes, and age in air for 12 hours after stirring to obtain WO 3 Precursor sol. in WO 3 The carboxylated graphene quantum dots added in the precursor sol, the concentration is 0.06g / L, and the ultrasonic vibration is 30min, so that the graphene is evenly disp...

Embodiment 3

[0036] The parameters of the tungsten oxide-graphene composite film prepared by dipping and pulling method are the same as those of the comparative example. Weigh 9.9g of sodium tungstate, dissolve it in 20mL of ultrapure water, and add concentrated hydrochloric acid dropwise during stirring to adjust the pH to 3 to prepare 0.8mol / L sodium tungstate solution A. Take 0.96 g of acetic acid and dissolve it in 20 mL of ultrapure water to prepare acetic acid solution B with a concentration of 0.8 mol / L. Weigh 9.16 g of sodium hexametaphosphate and dissolve it in 10 mL of ultrapure water to obtain sodium hexametaphosphate solution C with a concentration of 1.5 mol / L. Mix and stir solution A and solution B for 10 minutes, then add solution C, continue stirring for 10 minutes, and age in air for 36 hours after stirring to obtain WO 3 Precursor sol. in WO 3 Add hydroxylated reduced graphene oxide to the precursor sol, the concentration is 0.18g / L, ultrasonic vibration for 30min, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com