Improved method for preparing silicon nitride anti-reflecting film of crystalline silicon solar cell

A technology of solar cells and anti-reflection films, applied in circuits, electrical components, gaseous chemical plating, etc., can solve the problems of insufficient passivation effect and anti-reflection effect, poor compactness of SiNx, etc., and improve the photoelectric conversion efficiency. , improve uniformity and density, and improve the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Select the polysilicon raw silicon wafer with a resistivity of 0.5~6 and a crystal plane of (100), and the specific process is as follows:

[0021] 1. Wafer pretreatment:

[0022] (1) Chemical cleaning removes the surface damage of the silicon wafer and forms anti-reflection corrosion pits;

[0023] (2) The liquid phosphorus source diffuses to form a PN junction;

[0024] (3) Plasma etching to remove the PN junction at the edge of the silicon wafer;

[0025] (4) Secondary cleaning to remove the phosphosilicate glass on the surface of the silicon wafer;

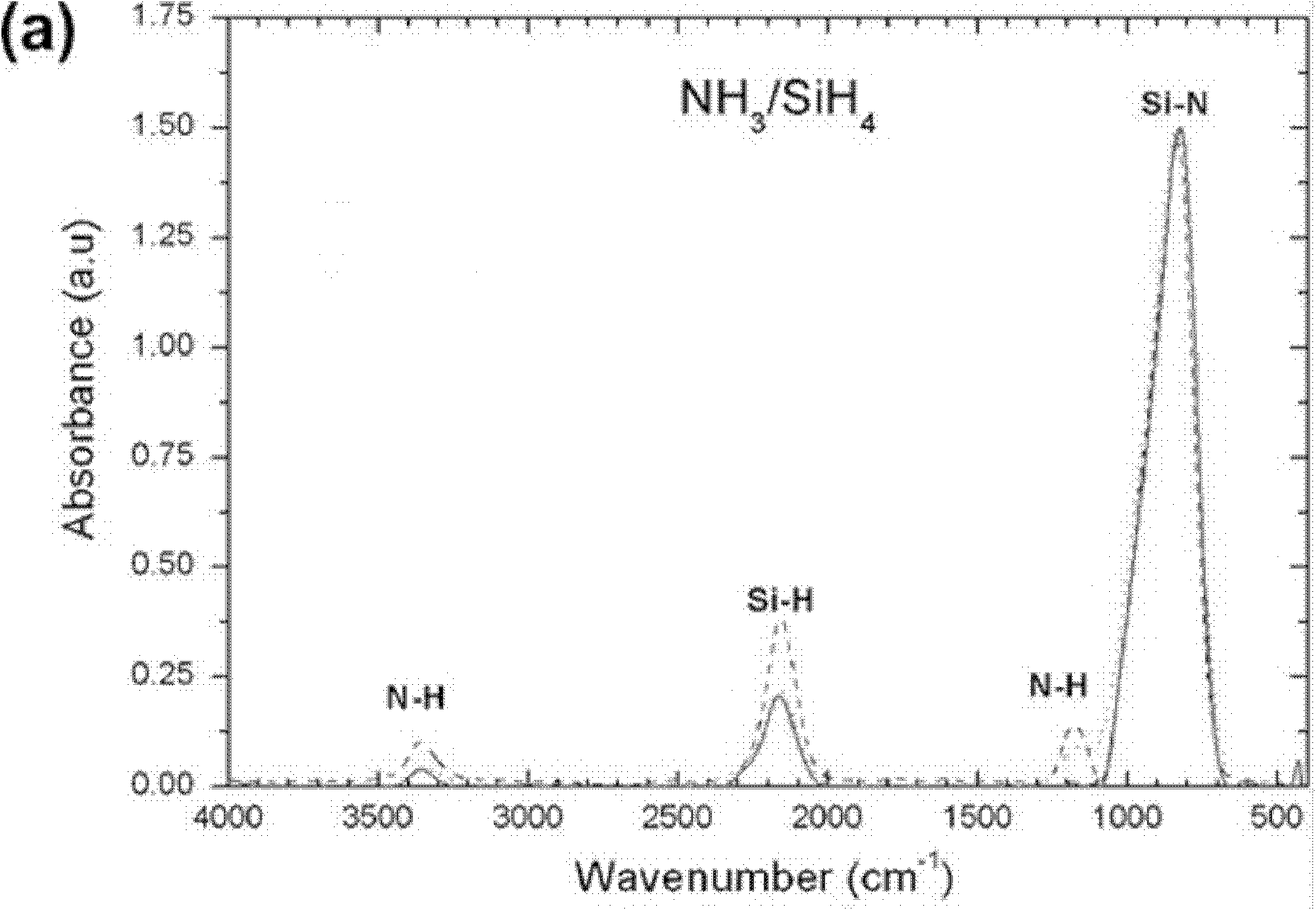

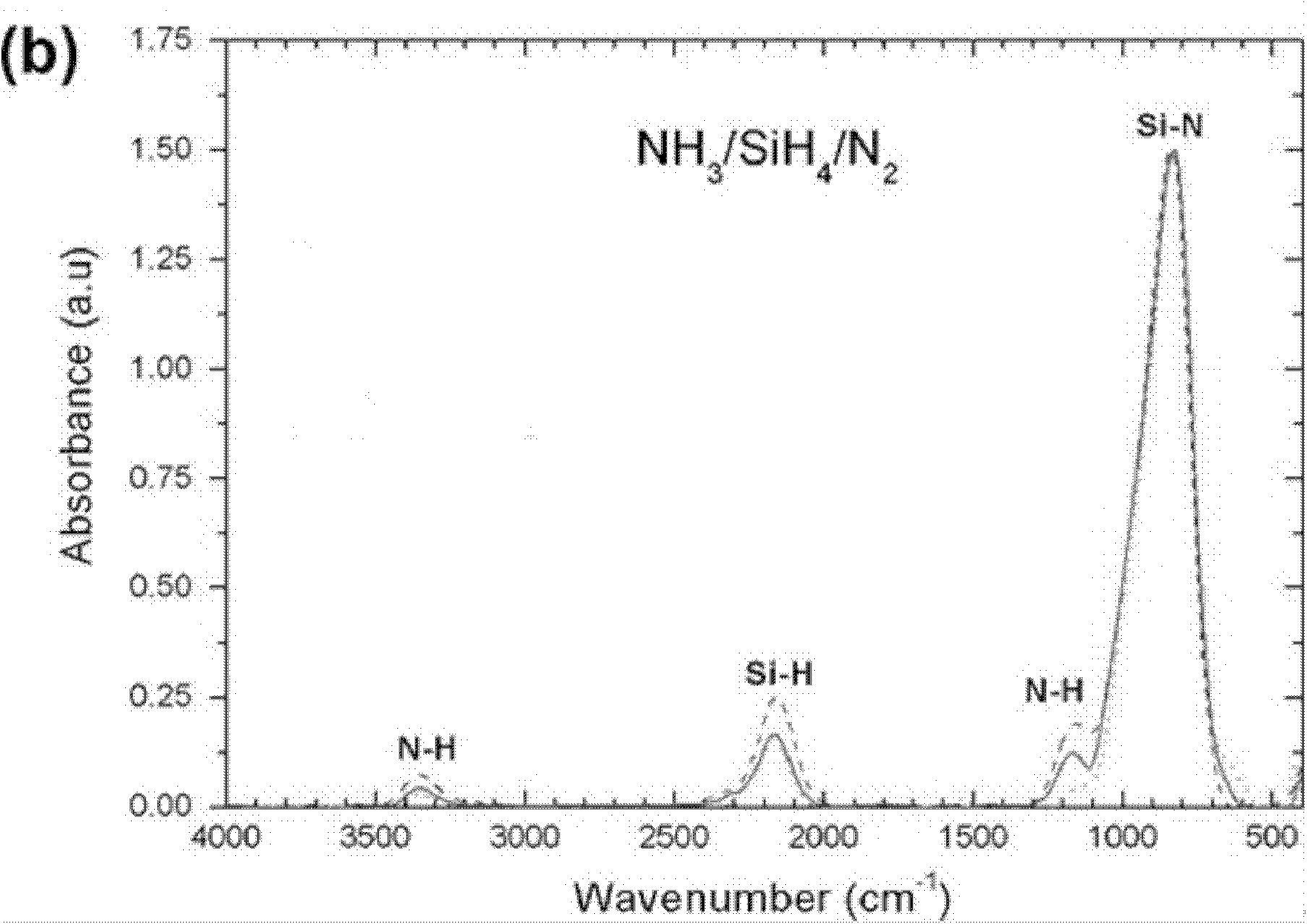

[0026] 2. Deposition of SiN by plasma enhanced chemical vapor deposition (PECVD) x Anti-reflective coating, the coating process is:

[0027] Heat the furnace tube to a certain temperature, place the graphite boat filled with silicon wafers in the furnace tube, heat to the preset temperature, pump the cavity to a vacuum state, and feed a certain flow of NH 3 Pre-deposit the silicon wafer for 3 minutes, and feed NH a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com