Pile-soil combined action supporting device and construction method thereof

A technology of joint action and support device, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problem that the shear strength of the upper soil cannot be fully utilized, the advantages of the soil itself cannot be utilized, and the soil arch cannot be formed. effect and other problems, to achieve the effect of reducing the amount of uneven settlement and deformation, reducing the risk of landslides, and increasing the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The directions shown in the accompanying drawings are up, down, left, and right.

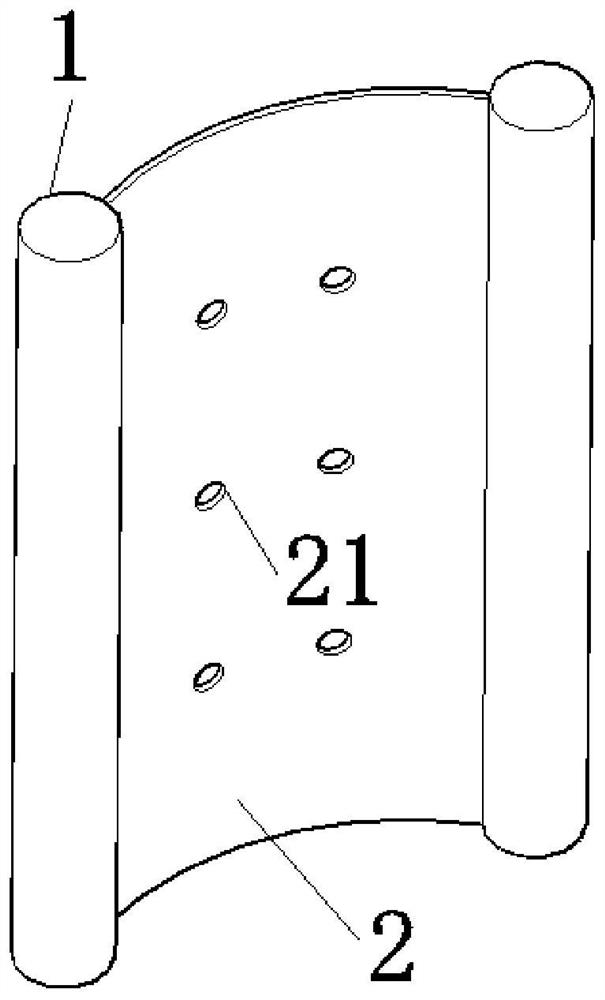

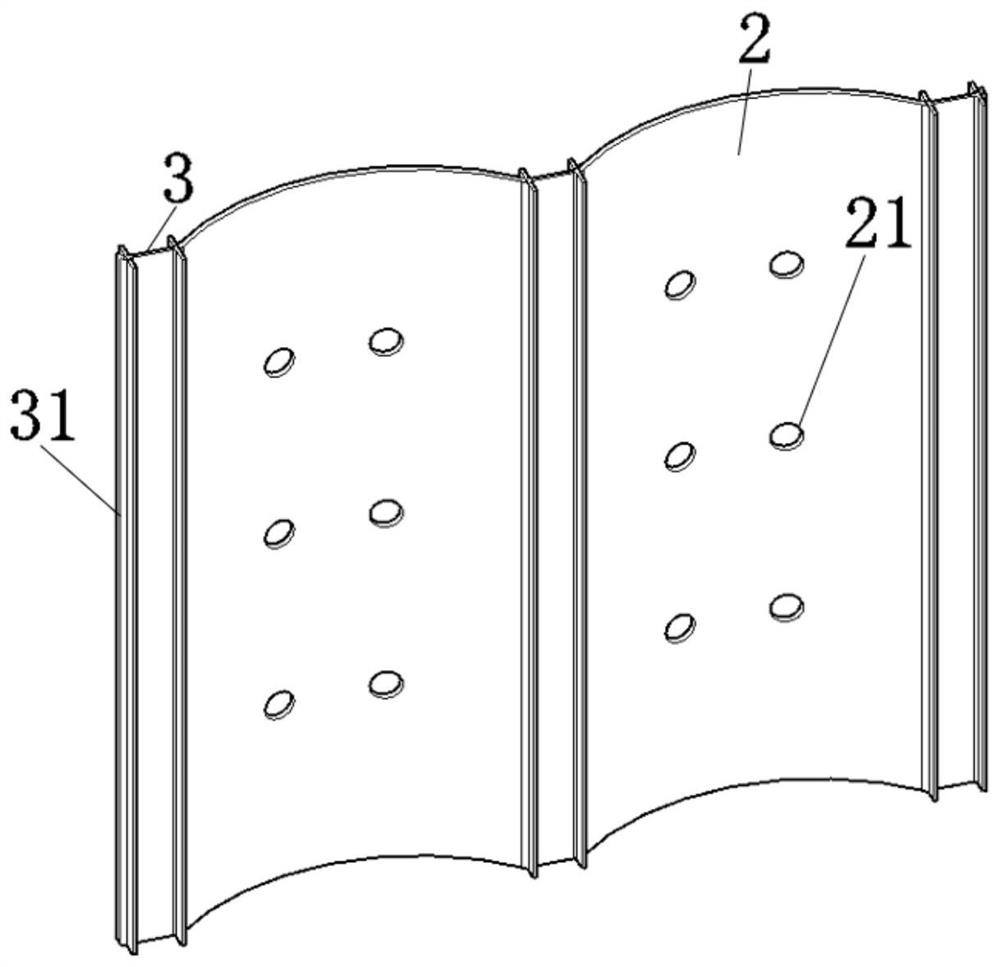

[0030] Such as Figure 1~2 The supporting device for pile-soil interaction includes bored cast-in-place pile 1 and steel plate 2, the bored cast-in-place pile 1 is inserted with H-shaped steel 3, and the steel plate 2 is an arc-shaped steel plate 2 that conforms to the radian of a reasonable arch axis in actual engineering. According to actual needs, a certain number of support devices are set up on the slope surface of the slope as needed.

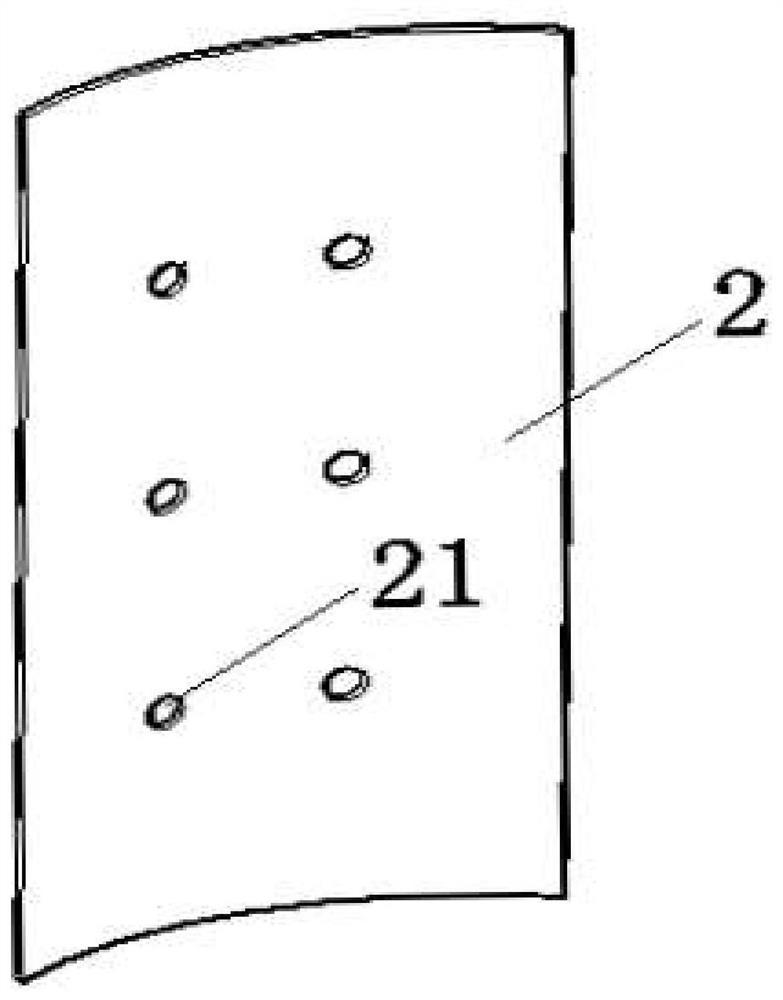

[0031] Such as image 3 The surface of the arc-shaped steel plate 2 has a through hole 21, the through hole 21 is circular, elliptical or any polygon, preferably circular, which is beneficial to soil drainage. The surface of the arc-shaped steel plate 2 has an anti-corrosion paint layer, and the anti-corrosion paint is existing. Bottom surfaces of the bored cast-in-place pile 1 and the steel plate 2 are lower than the sliding surface of the slope....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com