Automatic processing device for blast holes with karst caves

A processing device and blast hole technology, applied in blasting and other directions, can solve the problems of clogging of woven bags, poor blast hole effect, etc., and achieve the effect of increasing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

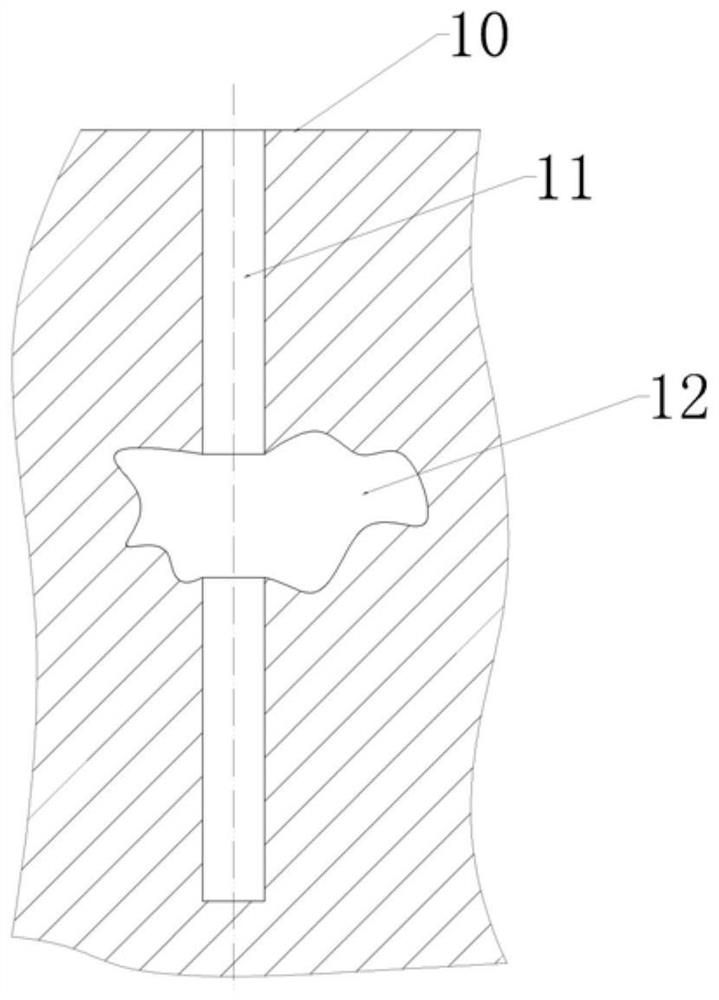

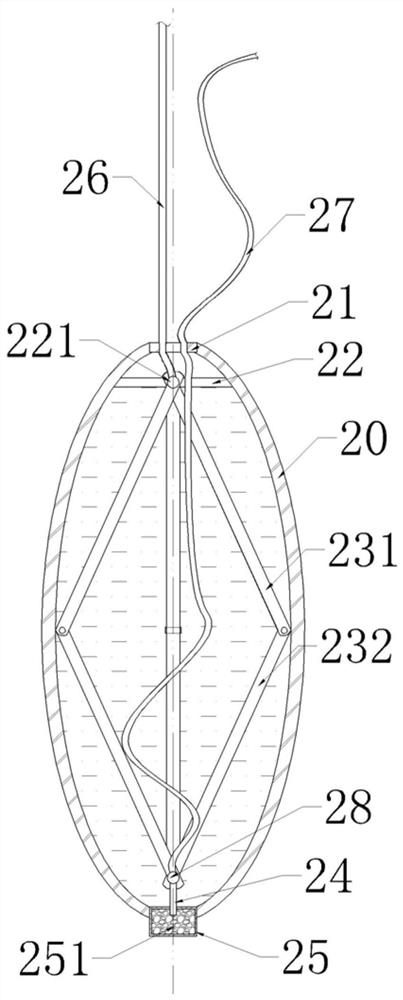

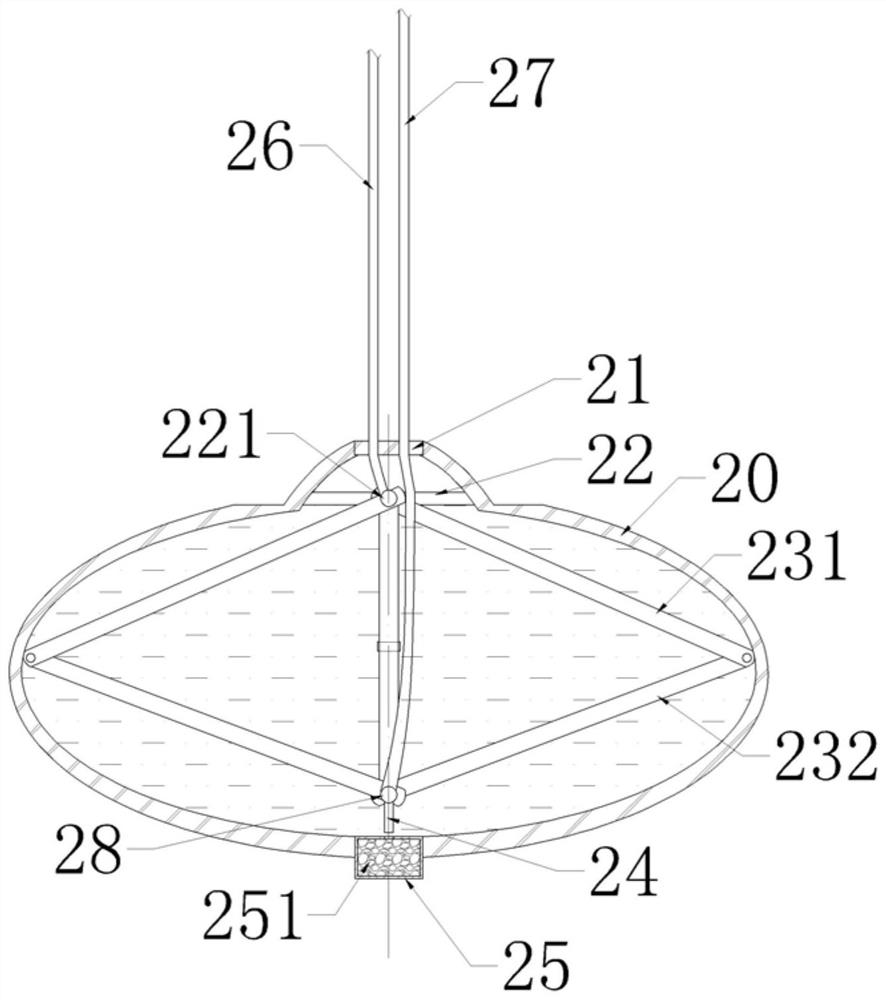

[0027] The reference signs in the accompanying drawings include: rock 10, blast hole 11, cave 12, capsule 20, fixed block 21, partition 22, first hinge shaft 221, first connecting rod 231, second connecting rod 232, Plunger 24, fixed box 25, sodium peroxide 251, first stay cord 26, second stay cord 27, second hinge shaft 28.

[0028] The embodiment is basically as attached figure 1 - attached image 3 Shown: the automatic processing device for blastholes with karst caves, including a capsule body 20, a telescopic mechanism and a fixing box 25.

[0029] like figure 1 As shown, a blasthole 11 is opened in the rock 10, and a karst cave 12 is located in the middle of the blasthole 11, and the karst cave 12 divides the blasthole 11 into upper and lower parts. If there is no karst cave 12 in the inside of blast hole 11, when charging (for the blast hole that the aperture is D90mm deep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com