An optical system adjustment device capable of real-time compensation and its adjustment method

An optical system and real-time compensation technology, applied in the direction of using optical devices, optics, optical components, etc., can solve the problems of wasting time, the adjustment personnel cannot directly obtain the detection data of optical lenses, and the interval compensation data cannot be obtained, so as to increase the reliability Operability, improve the efficiency of assembly and adjustment, and the effect of loose lens tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

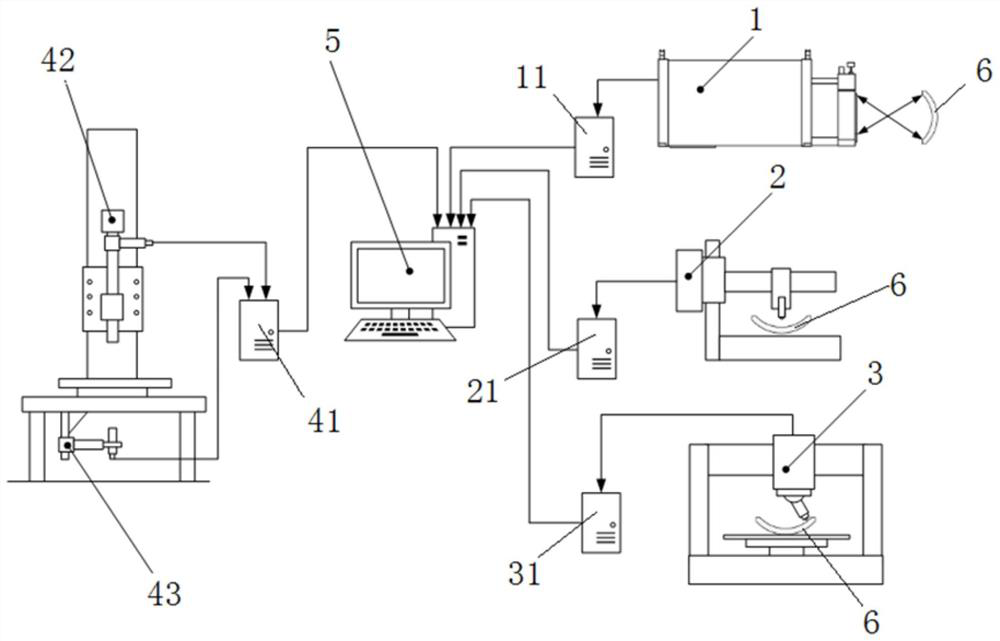

[0021] Such as figure 1 As shown, the real-time compensable optical system adjustment equipment of the present invention includes a laser interferometer 1, a depth measuring instrument 2, an interferometer 3, a centering instrument 42, a mirror locator 43, and a calculation unit 5; a laser interferometer host 11, Depth measuring instrument host 21 and interferometer host 31 are respectively connected to the input of the calculation unit, and the output of the centering instrument 42 and the mirror locator 43 is connected to the input of the calculation unit 5 through the adjustment host 41; the laser interferometer 1, the depth measuring instrument, the interferometer The measuring instrument transmits the measured surface shape accuracy, thickness, and surface curvature radius of each lens to the calculation unit 5 respectively.

[0022] For the first lens of the optical system, the calculation unit 5 calculates the adjustment guidance data according to its theoretical adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com