Sample centrifugal management system and method for intelligent laboratory

A management system and laboratory technology, applied in the direction of analyzing materials, instruments, etc., can solve problems such as being unsuitable for intelligent assembly lines, unable to achieve multiple parallel work, exceeding the optimal time for sample detection, etc., to achieve continuous and stable long-term work, The effect of maximum sample processing efficiency and avoiding pipeline congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

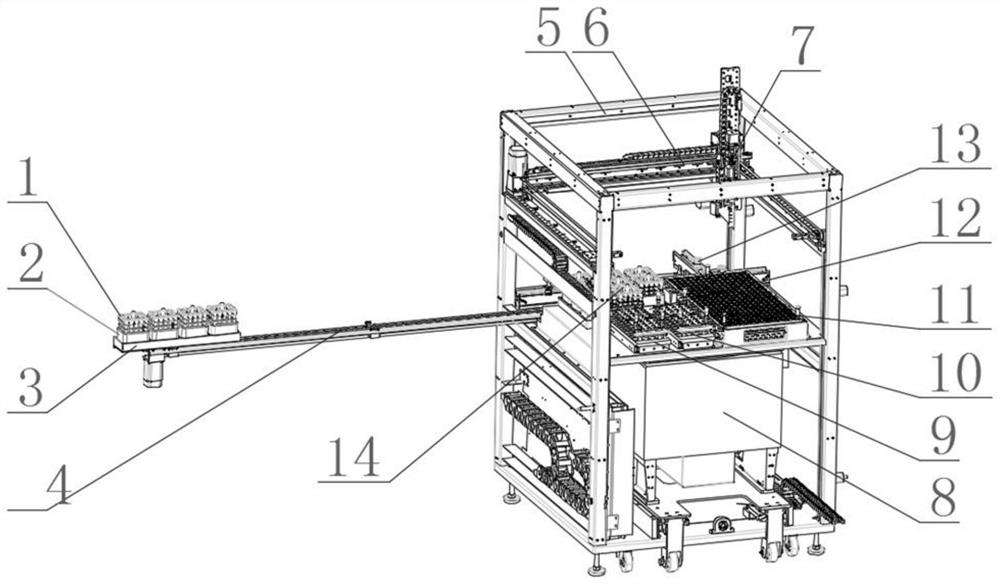

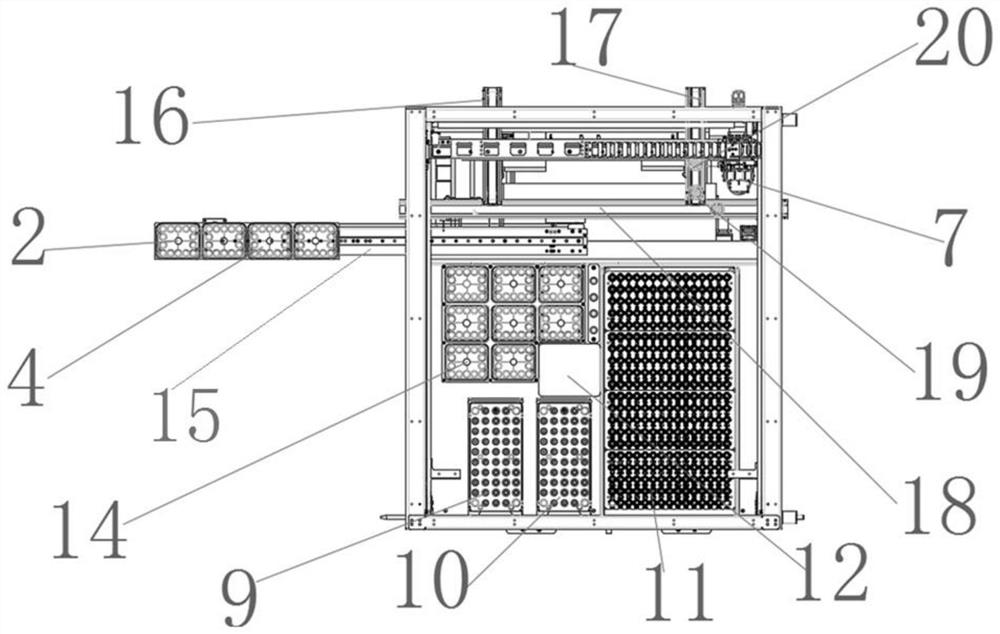

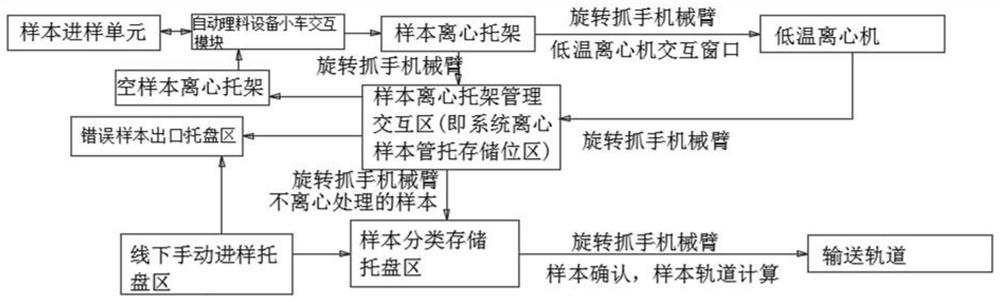

[0039] Such as Figure 1 to Figure 3 As shown, a sample centrifugation management system of an intelligent laboratory in the present invention includes a sample sampling unit and at least one sample centrifugal processing unit, the sample sampling unit is connected to the sample centrifugal processing unit, and the sample sampling unit is externally connected to a sample loading system, the sample loading system can use a specific sampling device to insert the blood sample tube 1 into the sample sampling unit through the sample loading system; the sample centrifugal processing unit is externally connected to a detection instrument, and the detection instrument is used to perform the centrifugation of the sample. The samples after unit processing are tested;

[0040] The sample centrifugal processing unit is a device for centrifuging and managing the sample obtained from the sample sampling unit; the sample sampling unit is a device for transferring the blood sample tube 1 to t...

Embodiment 2

[0061] Such as Figure 1 to Figure 3 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, multiple sample sampling units are used, and multiple sample sampling units are arranged in a row along the interior of the sample centrifugal processing unit. , and concatenated together.

[0062] The system of this embodiment connects the sample injection unit and multiple sample centrifugation management units in series through the interactive module 4 of the automatic material sorting equipment trolley, so that the maximum sample processing efficiency can be exerted at the same time when multiple units are connected in series.

[0063] In this embodiment, the two sample sampling units are arranged in a row, that is, they are connected together in series. At this time, one end of the transport track 15 passes through the first sample sampling unit and extends to the second sample sampling unit. Inside the sampling unit, the other end of the del...

Embodiment 3

[0065] Such as Figure 1 to Figure 3 As shown, the difference between this embodiment and Embodiment 2 is that this embodiment also includes an offline manual sampling tray area 10, and the offline manual sampling tray area 10 is arranged on the front side of the centrifuge inlet 12, so The offline manual sample injection tray area 10 is used for manually adding samples or for emergency needs.

[0066] This embodiment ensures that the batch sample injection interface (by means of the sample injection unit) and the manual input and output interface (by means of the offline manual sample injection tray area 10) are combined, and the implementation efficiency is better.

[0067] In the system of the present invention, the low-temperature centrifuge 8 is stable and reliable, and can work continuously and stably for a long time; the batch sample injection interface is combined with the manual sample entry and exit interface; the processed samples are kept sealed, classified central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com