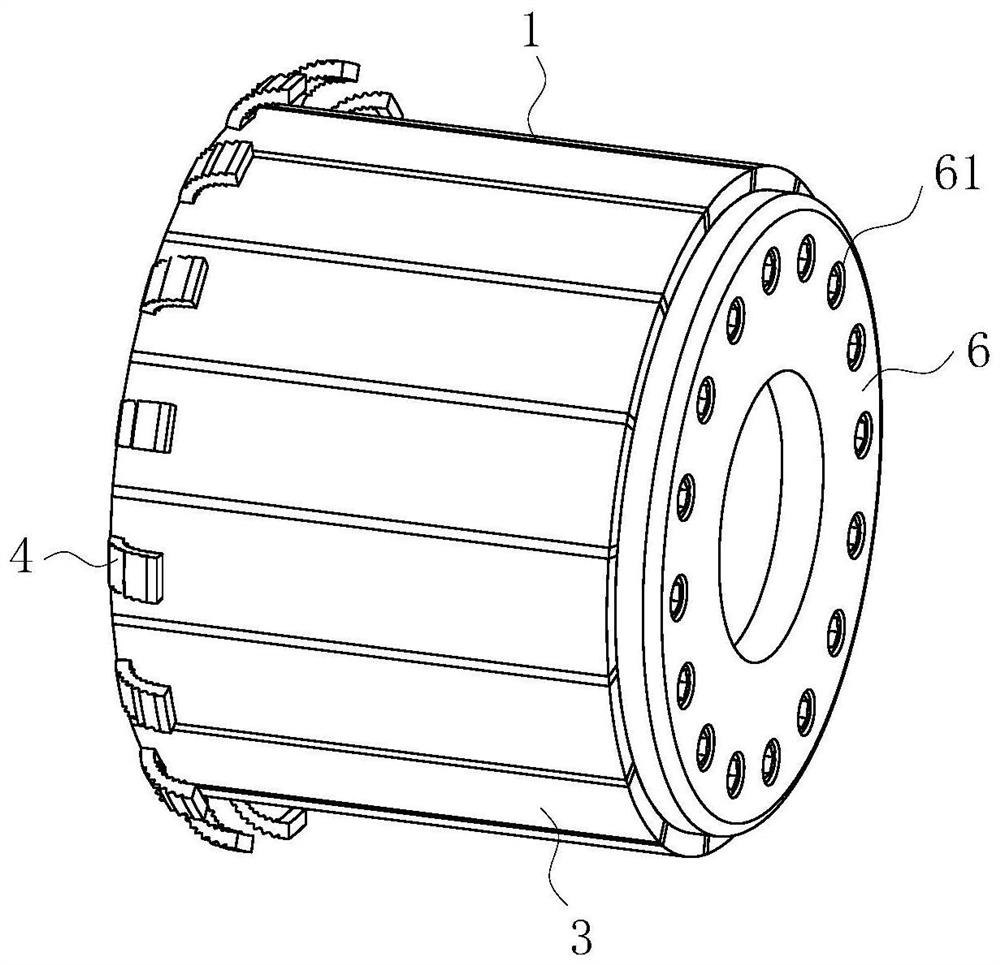

Motor and motor assembly

A technology of motor components and components, which is applied in the direction of electric components, electrical components, circuits, etc., can solve the problems of commutator piece waste, etc., and achieve the effects of improving utilization rate, improving maintenance and replacement efficiency, and improving connection stability and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

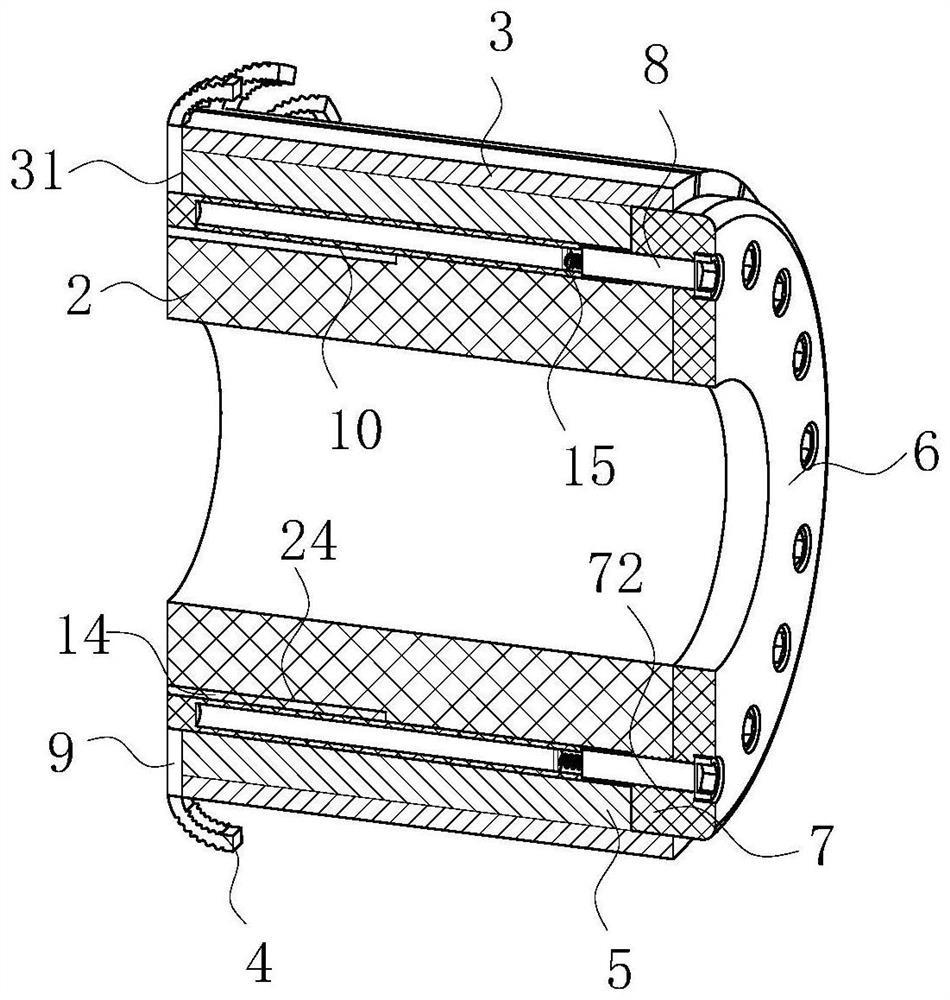

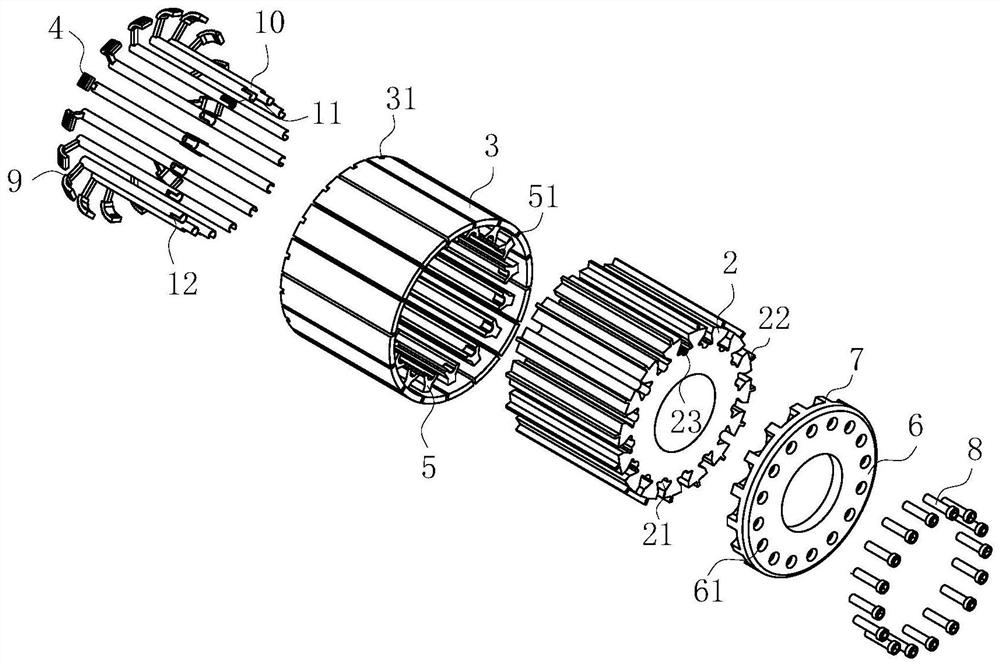

[0026] As an embodiment of the present invention, the end of the reversing segment 3 is provided with an engaging groove 31, and an elastic metal block 9 is squeezed and engaged in the engaging groove 31; The top end is fixedly connected with the lead terminal 4, and the bottom end of the elastic metal block 9 is connected to the insulating conduit 10; the insulating conduit 10 is inserted into the bottom end surface of the dovetail inclined block 5; the bottom cavity wall of the dovetail slot 21 is A limit slot 24 is set up, and a splice strip 14 is inserted into the limit slot 24; the splice strip 14 is fixed to the bottom end of the insulating conduit 10; 5 After being slid and inserted into the dovetail slot 21, the insulating conduit 10 can be slid and inserted along the bottom end surface of the dovetail slant block 5 to the connection between the dovetail slant block 5 and the dovetail slot 21, and at the same time, the insertion of the bottom end of the insulating condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com