Underground coal flow visual detection method

A technology for visual detection and coal flow, applied in the field of visual detection, can solve the problem of low detection accuracy and achieve the effect of reducing resource costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

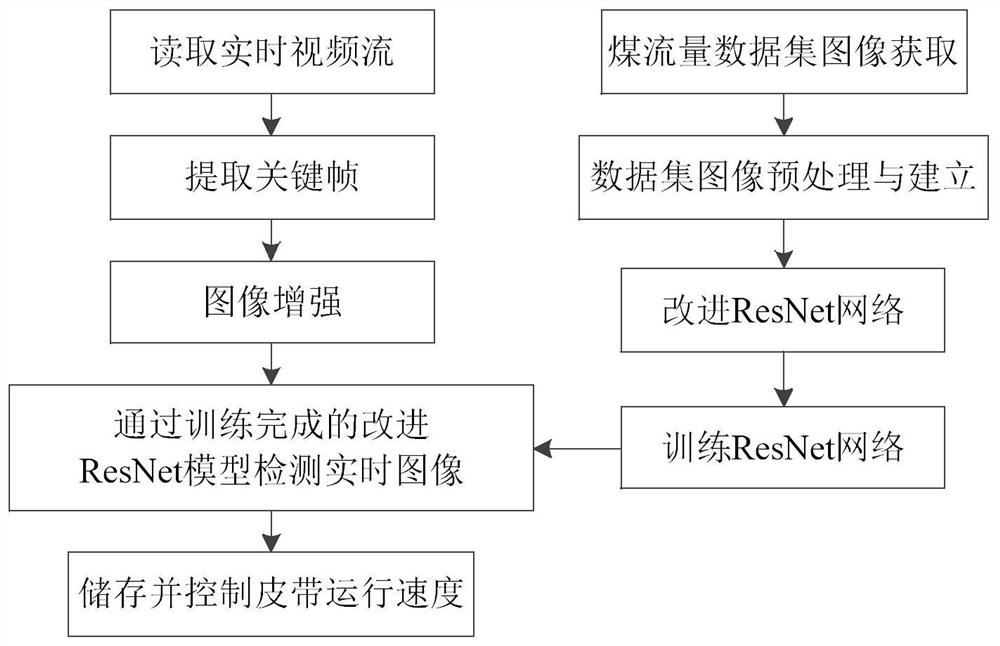

[0042] The present invention is an underground coal flow visual detection method, the process is as follows figure 1 Shown, specifically include the following steps:

[0043] Step 1. Adjust the angle of the original camera and read the real-time video stream;

[0044] The original camera has 2 million pixels, and the original size of the real-time video stream is 1920*1080 pixels. The vertical distance between the camera and the belt is 1.5m. On the basis of being perpendicular to the belt, adjust the angle of the camera from 0 to 15°.

[0045] Step 2, based on the video stream read in step 1, the image detection range is narrowed by extracting key frames and dividing image feature sensitive areas to obtain normalized key frame images;

[0046] The specific process of step 2 is:

[0047] Step 2.1, adjusting the speed of the original video...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com