PI protective film uncovering method of rigid-flex printed circuit board

A rigid-flex board and protective film technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of rigid board ink falling off easily, product quality is difficult to guarantee, and production efficiency is affected. Easy to remove the cover, ensure product quality, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The method for uncovering the PI protective film of the rigid-flex board of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

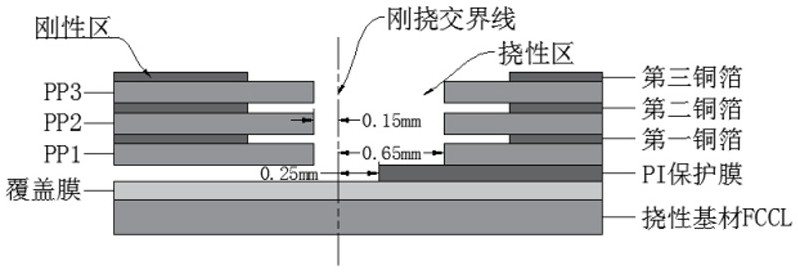

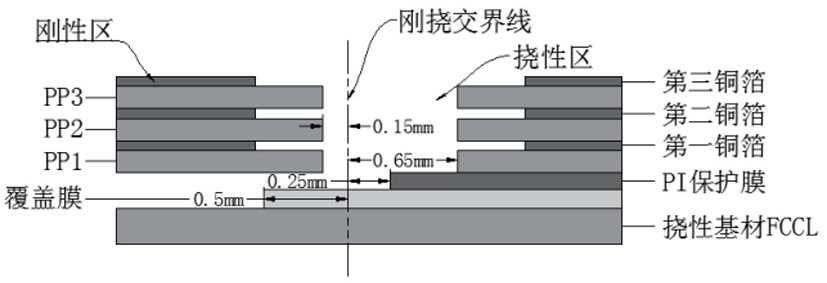

[0028] refer to figure 1 , a non-limiting embodiment of the present invention, a method for uncovering a PI protective film of a rigid-flex board, the method is suitable for uncovering a rigid-flex board with a large uncovering area of more than 6 layers, and the method adopts high flow Glue prepreg is used to make PP, and a slot with a certain width is burned out by UV laser machine for PP window opening. PP window opening is located on both sides of the rigid-flexible boundary line, which is divided into two parts by the rigid-flexible boundary line; When making the circuit, all the copper skin corresponding to the 0.4mm area of the inner edge of the PP is bitten off; a PI protective film is pasted on the bottom of the bottom PP, and the PI protective film i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com