Sealing member and casing including such member, gyratory crusher and installation method

一种回转破碎机、密封构件的技术,应用在发动机的密封、机械设备、发动机元件等方向,能够解决耗时等问题,达到省时安装的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided for thoroughness and completeness, and will fully convey the scope of the invention to Technical staff. Like reference numerals refer to like elements throughout.

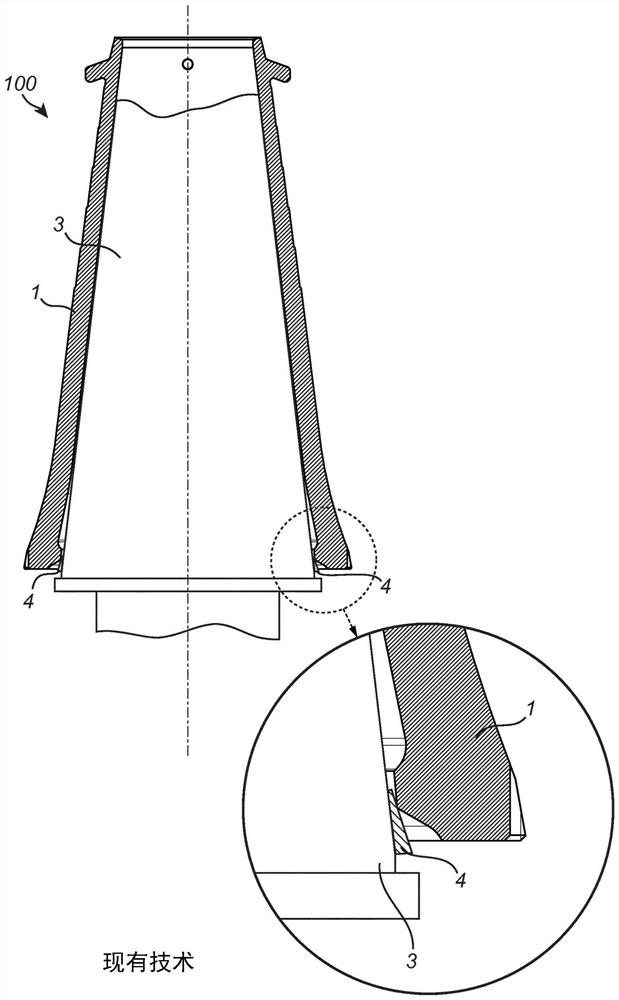

[0030] figure 1 A shows a part of a prior art gyratory crusher 100 comprising a casing 1 . The housing is centered around the main shaft 3 by means of a wedge 4 arranged between the outer wall of the main shaft 3 and the inner wall of the housing 1 . Typically four wedges 4 are provided, which are evenly distributed around the circumference of the outer wall of the main shaft 3 . Such casings 1 typically weigh between 5 and 13 tons. Wedge 4 is installed manually, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com