Floating-caliper brake

A floating caliper and brake technology, applied in the direction of brake type, axial brake, brake components, etc., can solve problems such as consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

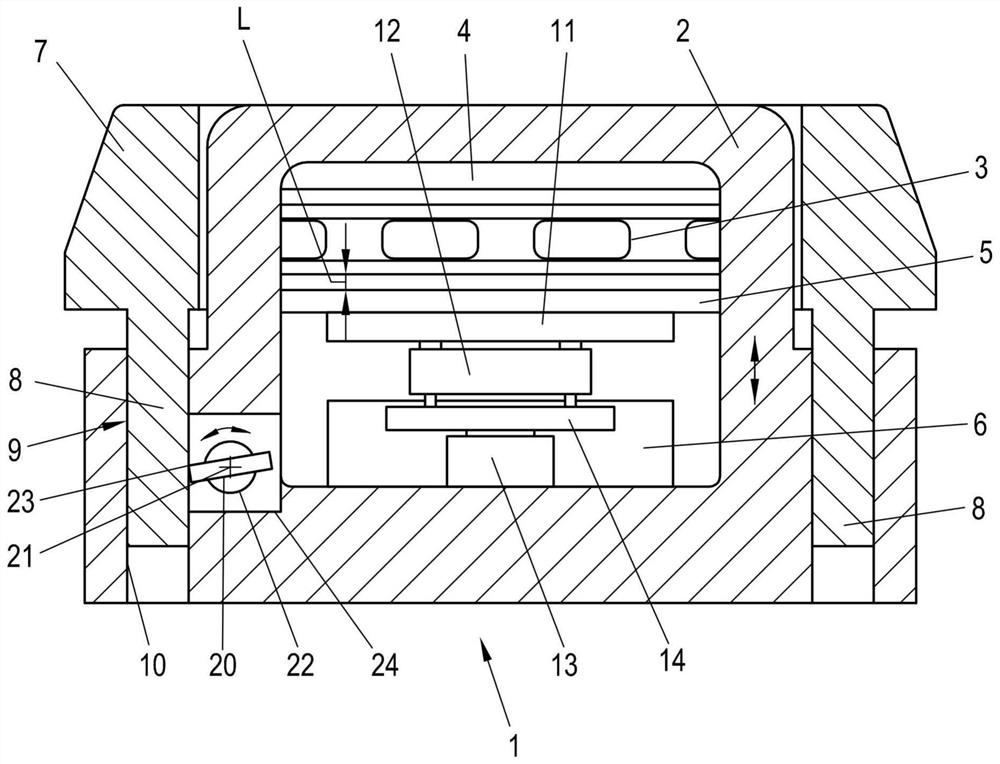

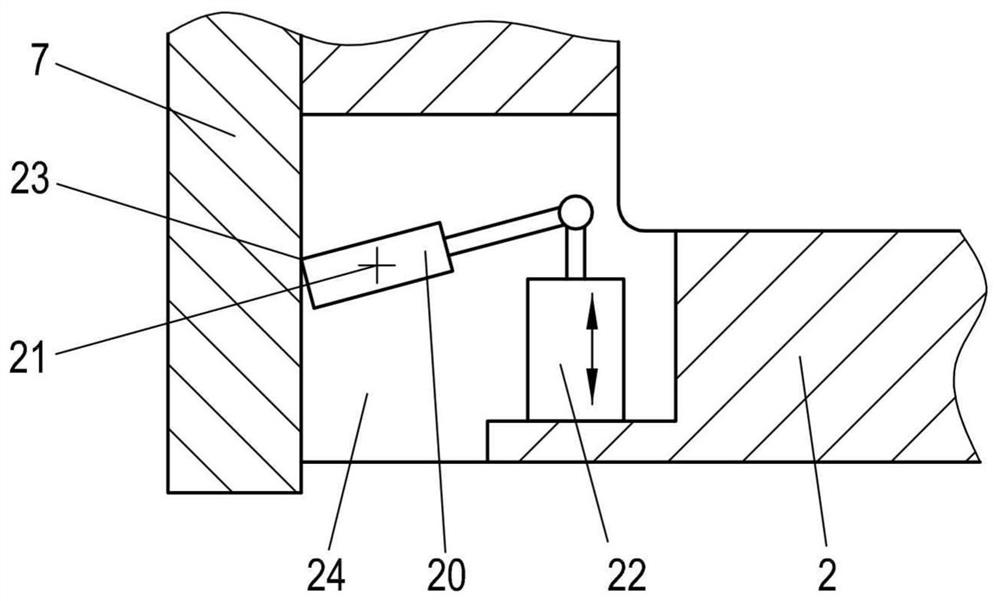

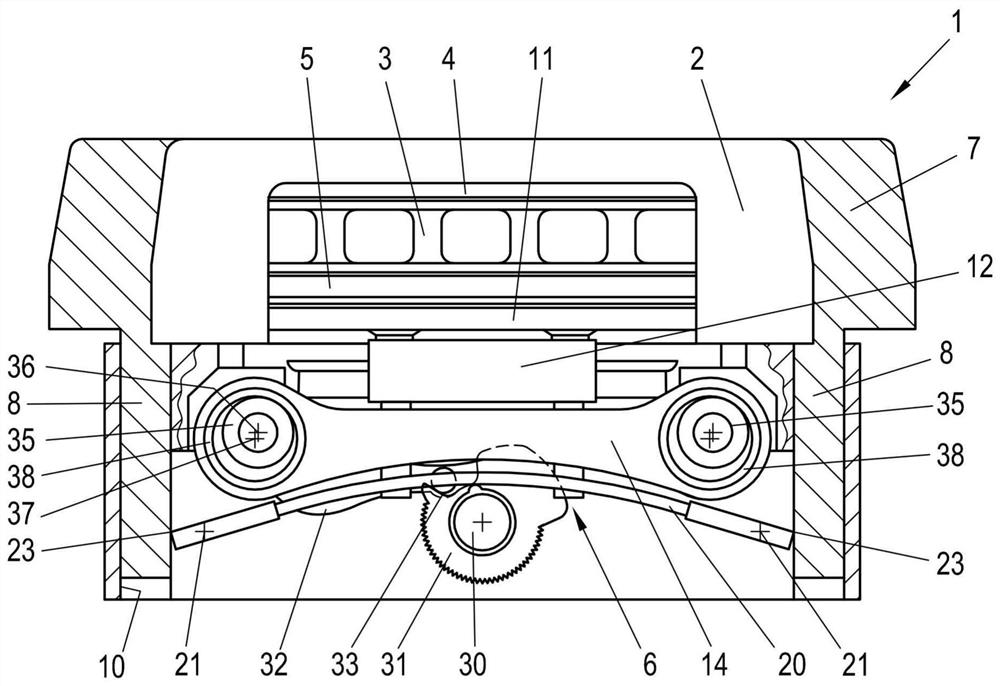

[0018] The floating caliper brake 1 essentially comprises a floating-mounted brake caliper 2 and a hold-down device 6 , on which the brake caliper is generally rigid (ie immovable relative to the brake caliper 2 but of course replaceable depending on requirements) A first brake lining 4 is provided on which, of course, a second brake lining 5 is arranged (replaceable depending on requirements, of course). For braking, the two brake linings 4 , 5 cooperate with the brake disk 3 . The second brake lining 5 can be moved relative to the brake caliper 2 by means of the pressing device 6 , in particular the second brake lining 5 can be moved towards the first brake lining 4 or away from said first brake lining. Pieces of movement. The floating caliper brake 1 serves to brake translational movements (eg in the case of lifting brakes or linearly moving mechanical parts) or rotational movements (eg of a vehicle wheel or a rotating mechanical part). For this purpose, the two brake lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com