Power cable pipeline cleaning device and using method thereof

A technology for cleaning devices and power cables, applied in the directions of cleaning methods and utensils, spray devices, chemical instruments and methods, etc., can solve the problems of secondary pollution, dust dissipation, cable core damage, etc., to avoid damage and dust escape. , the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

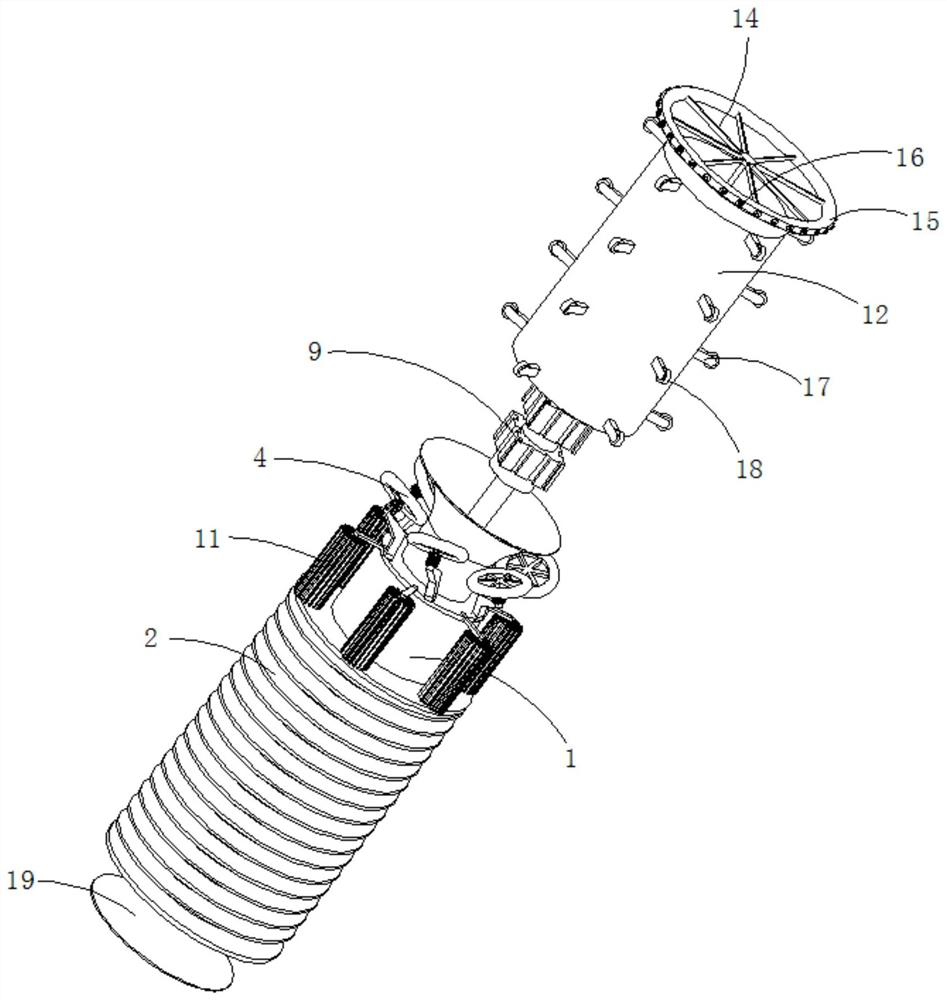

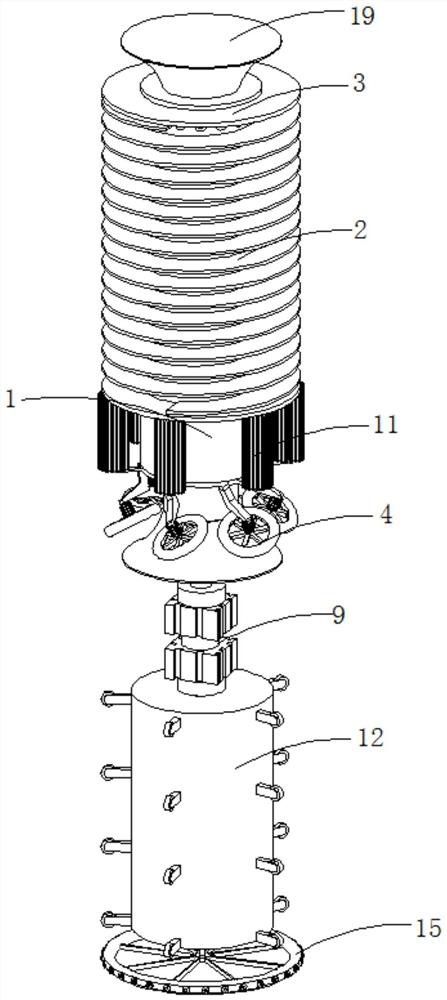

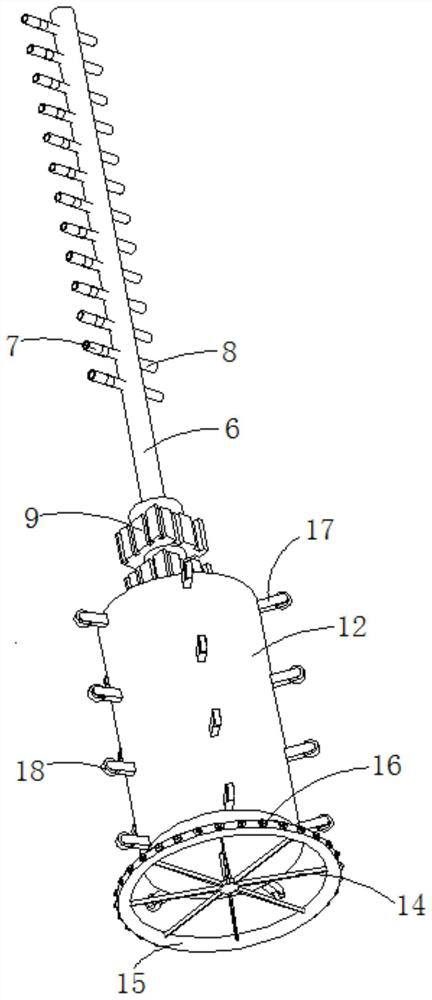

[0039] refer to Figure 1-8, a power cable duct cleaning device, including an installation cylinder 1, the installation cylinder 1 includes a hollow part 101 and a sealing part 102, the outer wall of the hollow part 101 is fixed with a shoveling piece 2 arranged in a spiral, and the two ends of the shoveling piece 2 It is also fixedly connected with the limit plate 3 set on the outer wall of the hollow part 101, and the outer wall of the sealing part 102 is provided with evenly distributed cleaning components. 4. A sealing cylinder 5 is rotatably connected to the installation cylinder 1, and the inner cavity of the sealing cylinder 5 is provided with a negative pressure air pipe 6, and the negative pressure air pipe 6 is provided with a uniformly distributed first dust removal pipe 7 and a second dust removal pipe 8. One end of a cleaning pipe 7 away from the negative pressure air pipe 6 is placed in the inner cavity between the sealing cylinder 5 and the installation cylinder...

Embodiment 2

[0046] refer to Figure 6-7 , a power cable duct cleaning device, which is basically the same as that of Embodiment 1, and furthermore, the thickness of the outer edge of the shovel sheet 2 is greater than the thickness of the joint between the shovel sheet 2 and the hollow part 101, so as to avoid the agglomeration of the removed concrete. In the gaps of the shovel sheet 2, the stability of the shovel is improved.

Embodiment 3

[0048] refer to Figure 1-7 , a power cable duct cleaning device, including an installation cylinder 1, the installation cylinder 1 includes a hollow part 101 and a sealing part 102, the outer wall of the hollow part 101 is fixed with a shoveling piece 2 arranged in a spiral, and the two ends of the shoveling piece 2 It is also fixedly connected with the limit plate 3 set on the outer wall of the hollow part 101, and the outer wall of the sealing part 102 is provided with evenly distributed cleaning components. 4. A sealing cylinder 5 is rotatably connected to the installation cylinder 1, and the inner cavity of the sealing cylinder 5 is provided with a negative pressure air pipe 6, and the negative pressure air pipe 6 is provided with a uniformly distributed first dust removal pipe 7 and a second dust removal pipe 8. One end of a cleaning pipe 7 away from the negative pressure air pipe 6 is placed in the inner cavity between the sealing cylinder 5 and the installation cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com