Metal bending equipment of automatic discharging mechanism for metal bending

An automatic cutting and metal technology, applied in the field of metal bending, can solve the problems of increasing manual workload and operation complexity, increasing bending time, employee and company losses, etc., to reduce manual cutting time, The effect of reducing collision sound and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

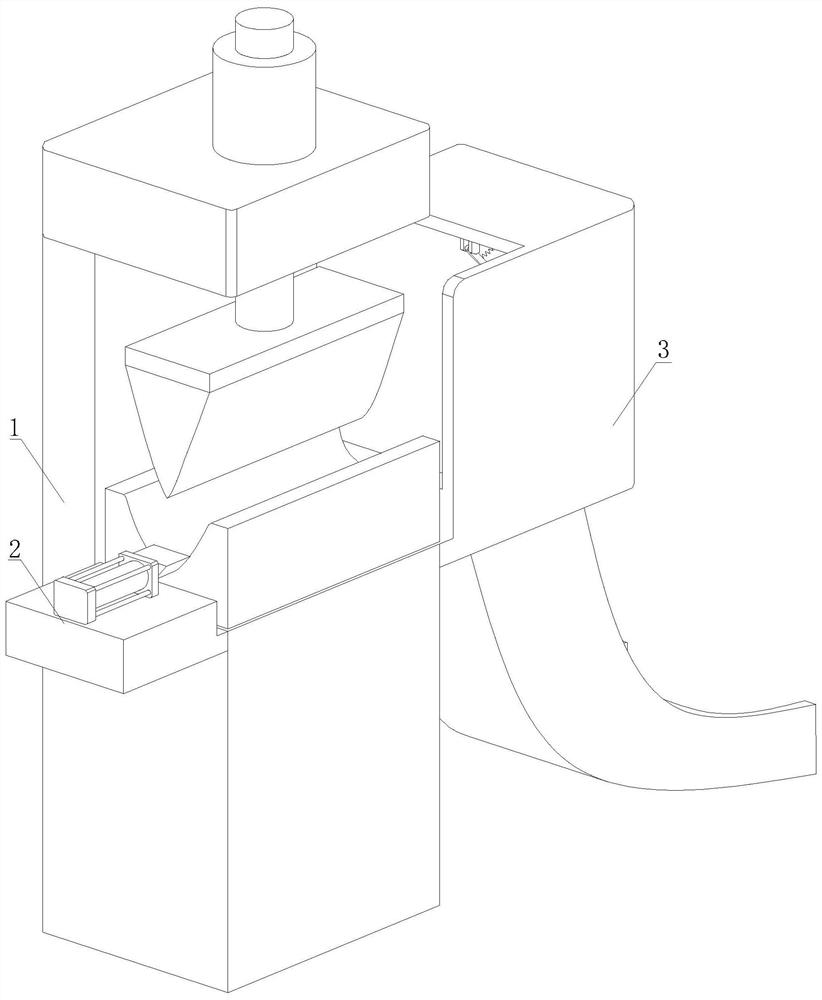

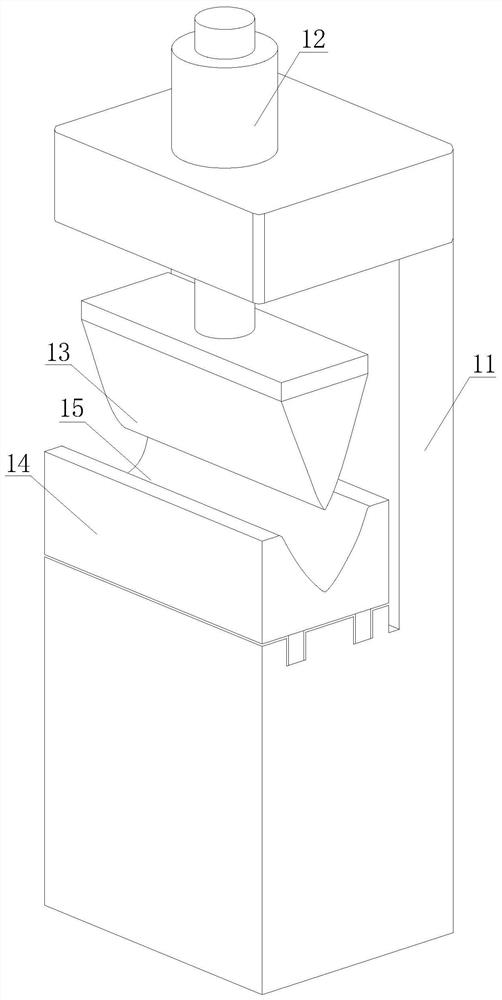

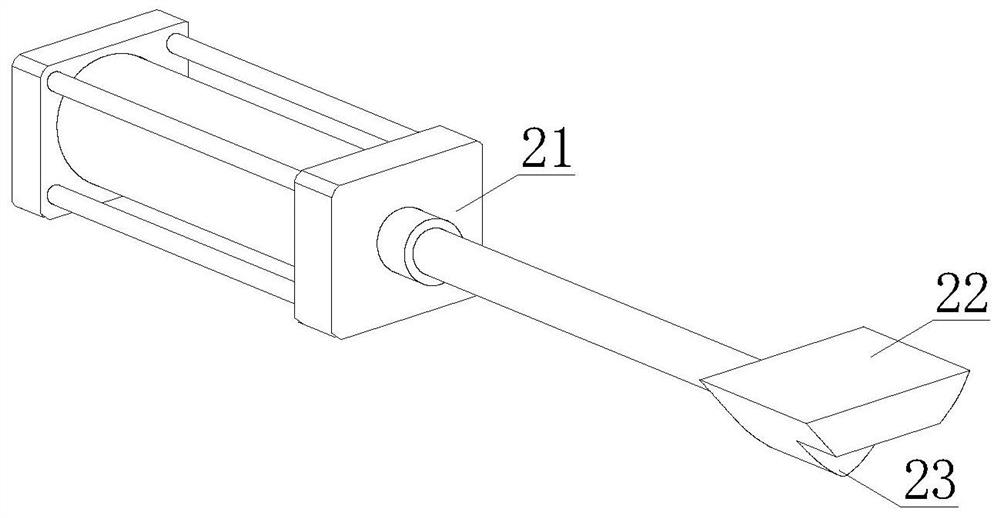

[0032] see Figure 1-2 , a metal bending equipment with an automatic blanking mechanism for metal bending, including a bending host 1, a blanking mechanism 2, a material guide mechanism 3 and a forming block 4, and the blanking mechanism 2 is arranged on one side of the bending host 1 At the upper end, the material guide mechanism 3 is set on the upper end of the other side of the bending main machine 1 corresponding to the unloading mechanism 2, and the forming block 4 is set on the upper end of the bending main machine 1. The bending main machine 1 includes a chassis 11, a hydraulic cylinder 12, and a pressure head. 13. The pressure bearing block 14 and the pressure groove 15, the hydraulic cylinder 12 runs through the upper middle of the chassis 11, the upper middle of the pressure head 13 is set at the lower end of the hydraulic cylinder 12, the pressure bearing block 14 is placed on the inner upper end of the chassis 11, and the pressure groove 15 Opened on the upper end ...

Embodiment 2

[0037] see Figure 1-3 , a metal bending equipment with an automatic blanking mechanism for metal bending, including a bending host 1, a blanking mechanism 2, a material guide mechanism 3 and a forming block 4, and the blanking mechanism 2 is arranged on one side of the bending host 1 At the upper end, the material guide mechanism 3 is set on the upper end of the other side of the bending main machine 1 corresponding to the unloading mechanism 2, and the forming block 4 is set on the upper end of the bending main machine 1. The bending main machine 1 includes a chassis 11, a hydraulic cylinder 12, and a pressure head. 13. The pressure bearing block 14 and the pressure groove 15, the hydraulic cylinder 12 runs through the upper middle of the chassis 11, the upper middle of the pressure head 13 is set at the lower end of the hydraulic cylinder 12, the pressure bearing block 14 is placed on the inner upper end of the chassis 11, and the pressure groove 15 Opened on the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com