Intelligent cable shearing device

A technology of shearing device and cutting device, which is applied in the direction of cable installation device, cable installation, cutting/split cable equipment, etc., which can solve waste, low work efficiency, inability to accurately determine cable fault point and complete cutting And other problems, to achieve the effect of preventing pollution and waste, effective insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

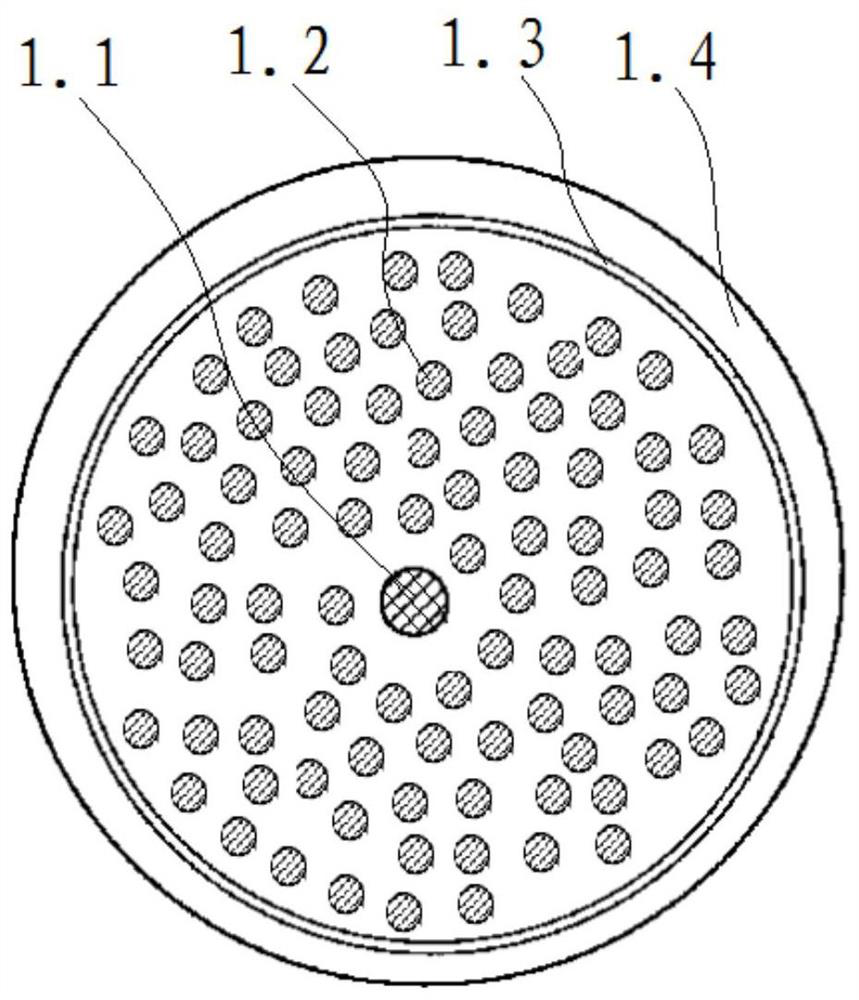

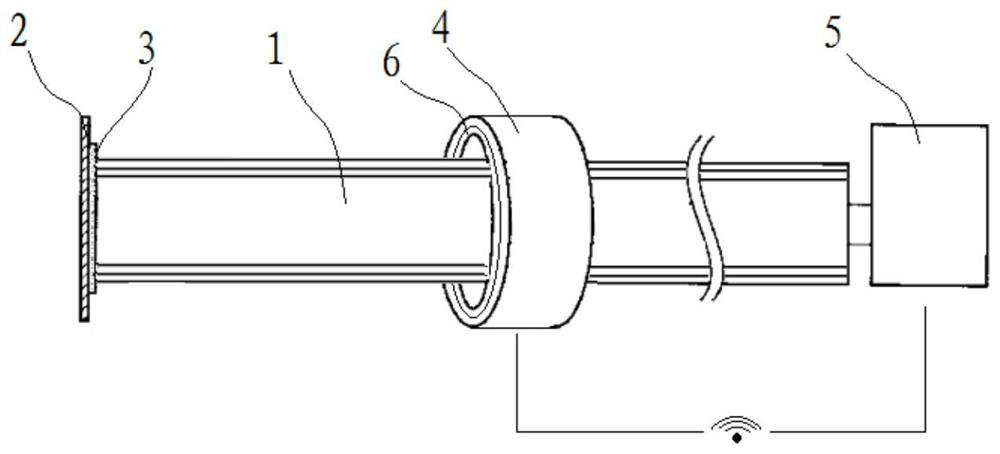

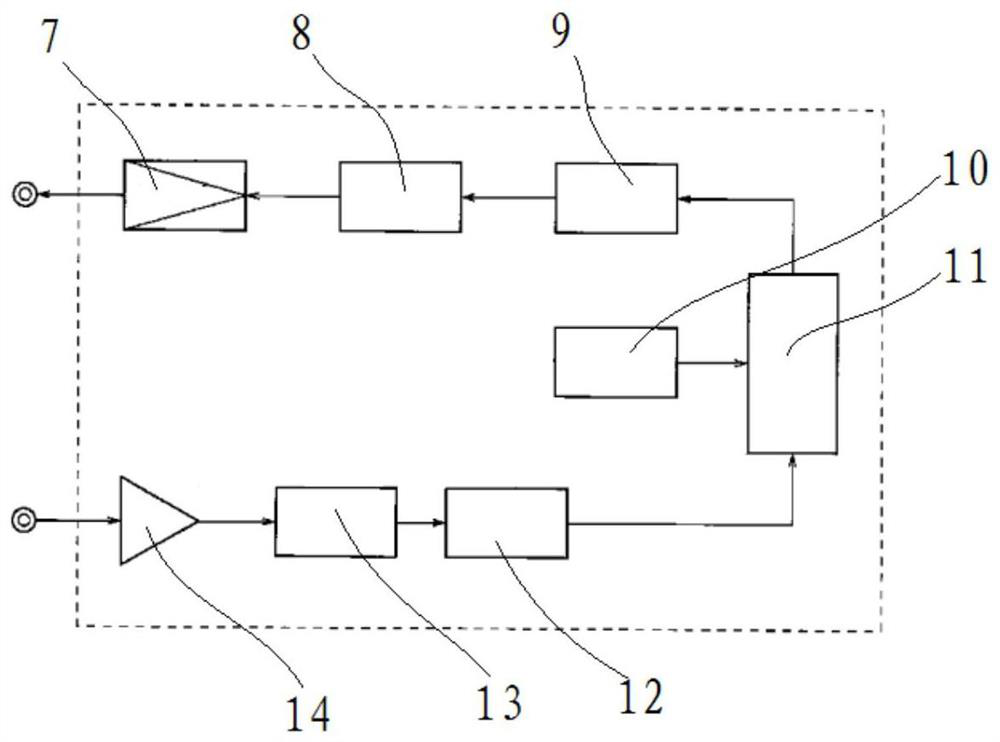

[0044] see Figure 1-6 , in the embodiment of the present invention, please refer to the appended Figure 1-6 , The present invention relates to an intelligent cable cutting device, which has a support plate 2, a cable cutting device, a control device for the cable cutter 4, and a pilot signal generating device. The side of the support plate 2 close to the cable 1 is coated with a conductive coating 3, the support plate 2 and the pilot signal generating device are respectively located at the two ends of the cable 1, and the cable 1 electrically connects the conductive coating 3 and the pilot signal generating device And transmit the pilot signal inside the communication cell 1.2 through the conductive coating 3 . On the section cable 1, a sensor unit 6 for detecting that the magnetic field leaks from the cable 1 to the outside is provided, and the sensor unit 6 judges whether the cutting operation needs to be completed; the frequency of the pilot signal generator is 100-10000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com