Energy-saving building outer wall structure and construction method

A technology of building exterior walls and construction methods, which is applied to building components, building structures, buildings, etc., can solve the problems of non-removable foaming agent, reduced thermal insulation effect, and troublesome demolition operations, so as to increase thermal insulation effect and facilitate construction and molding , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

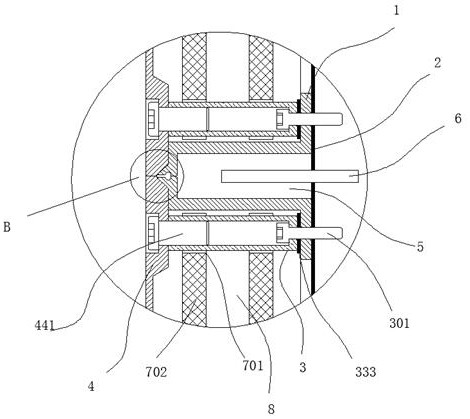

[0046]An energy-saving building exterior wall structure, comprising a frame 1, the side of the frame 1 facing the wall is provided with a slot 101, the end of the frame 1 away from the wall is provided with an opening, and an opening is provided on the outside of the opening There is an outer part 102; a film layer 2 is laid between the wall and the frame 1, and a plurality of through holes 102 are arranged on the outside of the slot 101 inside the frame 1, through which the through holes 102 Fitted with a connecting pipe 3, the bottom of the connecting pipe 3 is provided with an expansion screw 301, and the expansion screw 301 is driven into the wall after passing through the through hole 102; the end of the frame 1 away from the wall is covered There is a decorative panel 4, and a connecting screw 441 is fitted between the decorative panel 4 and the connecting pipe 3; a gap 5 for filling concrete is formed between two adjacent frames 1, and the position corresponding to the g...

Embodiment 2

[0048] A stepped groove 111 is provided at the outer edge position of the outer edge portion 102. When two adjacent outer edge portions 102 are spliced together, the stepped groove 111 is combined to form a filling groove. The walls of the side grooves are provided with arc-shaped grooves 112; the filling groove formed by closing the adjacent veneer panels 4 after combination; the filling groove formed by splicing the stepped grooves 111 can be filled with sealant, and the sealant can be effective after drying. For better sealing, the arc-shaped groove 112 can increase the filling thickness of the sealant and improve the sealing performance.

Embodiment 3

[0050] The outer edge of the outer part 102 protrudes outward to form a fitting part 122. After two adjacent outer parts 102 are combined, a V-shaped structure is formed through the fitting part 122, and the filling groove is exposed on the V. In the V-shaped structure, the outer surface of the decorative panel 4 is provided with a hypotenuse portion 441 corresponding to the V-shaped structure. The above-mentioned structure is mainly to extend the depth of the filling groove, so as to facilitate filling more sealant in the filling groove. To increase the sealing effect, secondly, it is to guide the installation of the veneer 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com