Inclined casting machine

A casting machine and tilting technology, applied in casting equipment, mold handling equipment, manufacturing tools, etc., can solve the problems of high labor intensity and poor working environment, and achieve the goal of improving efficiency, reducing strength and improving starting force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

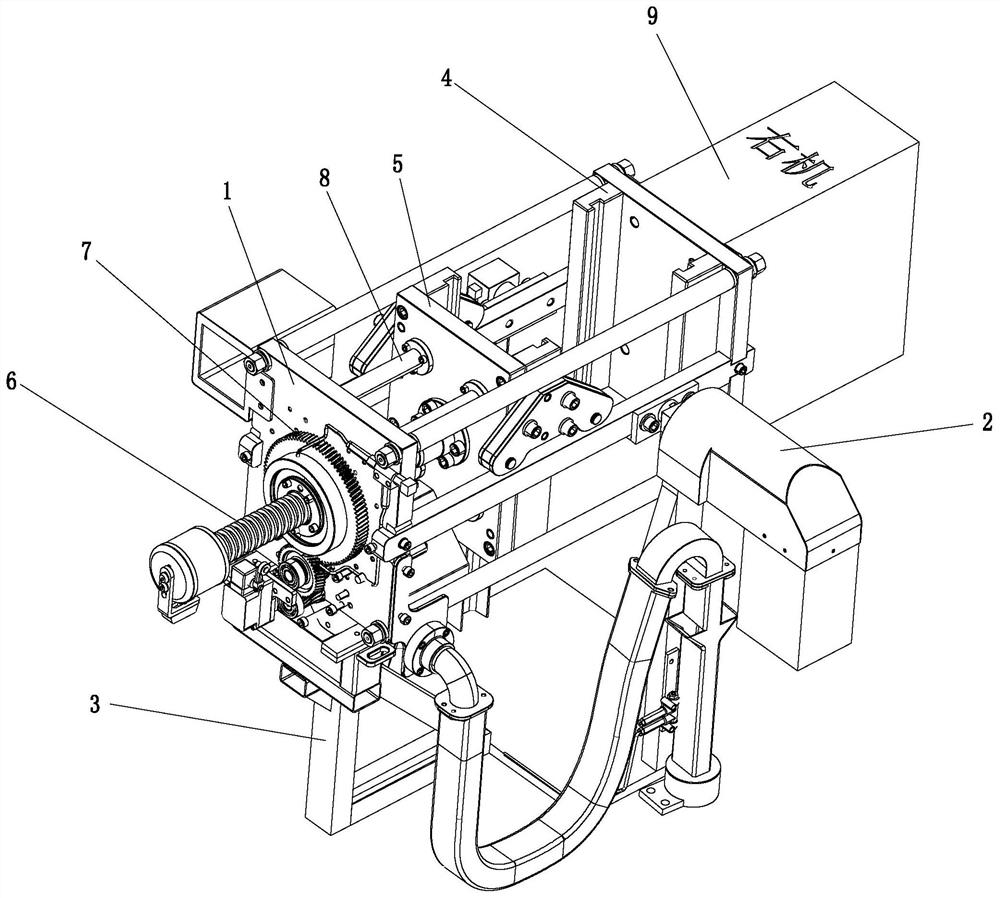

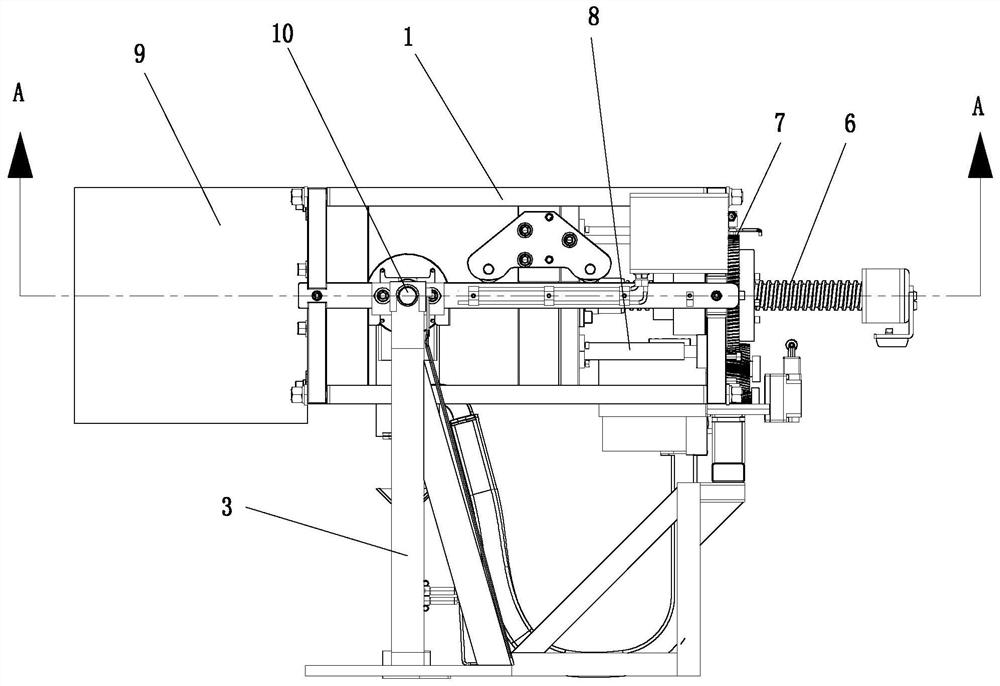

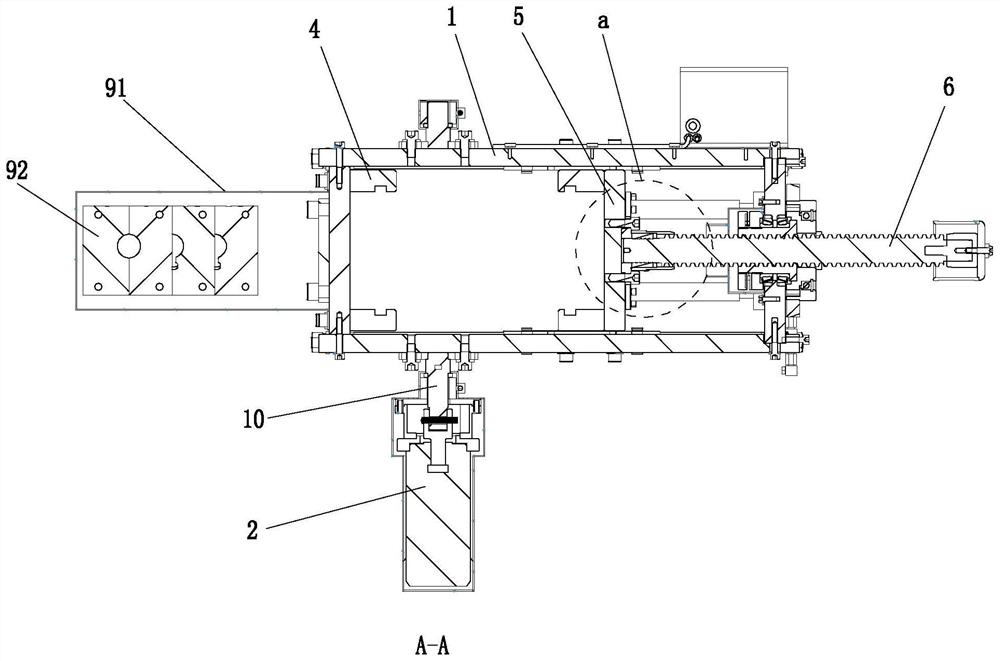

[0026] Such as Figure 1-Figure 11 As shown, the present invention comprises a frame 1, a tilting drive mechanism 2, an opening and closing mold mechanism, and an upper half mold and a lower half mold 14 that form an integral mould. The opening and closing mold mechanism includes an upper half mold mounting seat assembly 4, a lower half mold Die mounting base assembly 5, the upper half mold is fixed on the frame 1 through the upper half mold mounting base assembly, the lower half mold 14 is fixed on the sliding mechanism through the lower half mold mounting base assembly 5, and the frame 1 is The tilting drive mechanism 2 of the base 3 below the frame 1 drives the rotation and tilting casting; the sliding mechanism includes a servo motor, a screw 6, a nut 16, a beating disc 15, a beating disc 17, a transmission gear 7 and transmission with the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap