Remote control electric insulation clamp

A technology of insulating clamps and clamps, which is applied in the direction of clamps, overhead line/cable equipment, hand-held tools, etc., which can solve the problems that the wires cannot be clamped, time-consuming and labor-intensive, and the direction of the head of the insulating clamp cannot be adjusted freely. , to achieve the effect of reliable action, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

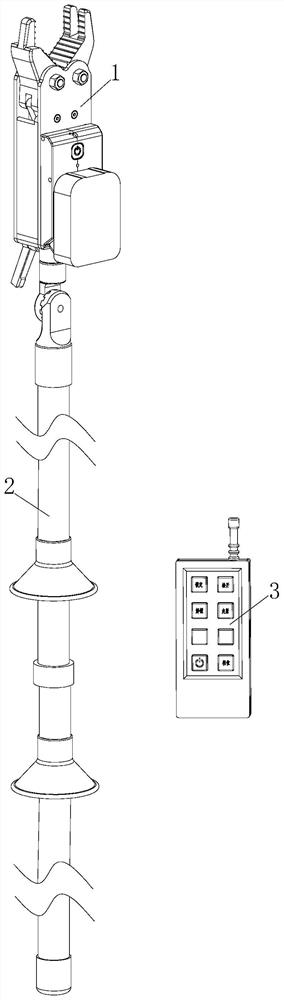

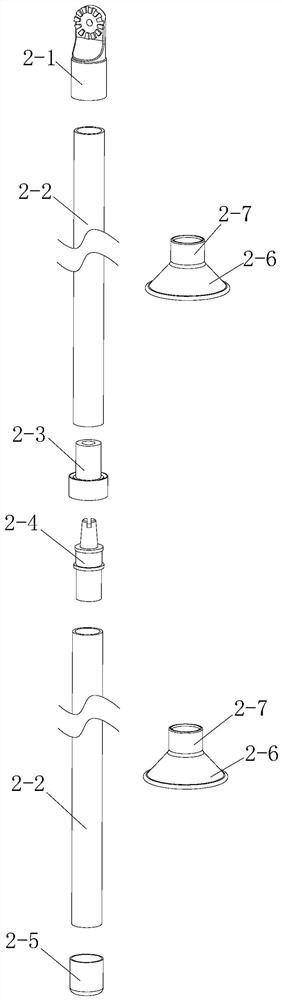

[0038] Example 1, see Figure 1-9 shown.

[0039] The remote control electric insulating clamp in this embodiment includes an insulating clamp main body 1, an insulating operating rod 2 and a remote control 3, the insulating clamp main body 1 is installed on the insulating operating rod 2, and the insulating clamp main body 1 is connected to the remote control 3 .

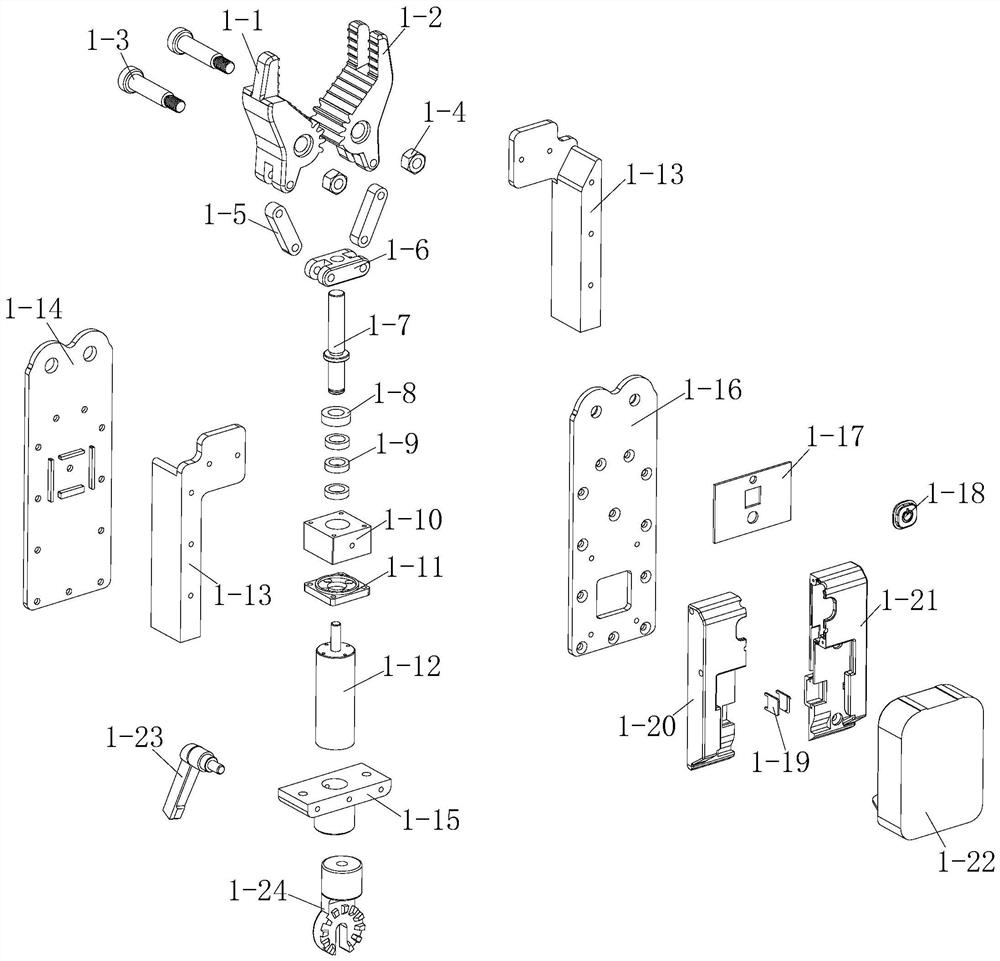

[0040] The main body 1 of the insulating clamp in this embodiment includes a collet, a collet driving mechanism, screws 1-3, nuts 1-4, a main body spacer 1-13, a left side plate 1-14, and a torx head connection seat 1-15 , right side board 1-16, main control circuit board 1-17, button cap 1-18, power contact piece 1-19, clamp female shell 1-20, clamp male shell 1-21, power supply 1-22, Thumb screw 1-23 and Torx head 1-24.

[0041] The collet in this embodiment is connected with the collet driving mechanism, and the collet includes a male tongs 1-1 and a female tongs 1-2, a male tongs 1-1 and a female tongs 1 -2...

Embodiment 2

[0058] Example 2 (flat type), see figure 2 , 3 and 7-12.

[0059] The remote control electric insulating clamp in this embodiment includes an insulating clamp main body 1, an insulating operating rod 2 and a remote control 3, the insulating clamp main body 1 is installed on the insulating operating rod 2, and the insulating clamp main body 1 is connected to the remote control 3 .

[0060] The main body 1 of the insulating clamp in this embodiment includes a collet, a collet driving mechanism, screws 1-3, nuts 1-4, a main body spacer 1-13, a left side plate 1-14, and a torx head connection seat 1-15 , right side board 1-16, main control circuit board 1-17, button cap 1-18, power contact piece 1-19, clamp female shell 1-20, clamp male shell 1-21, power supply 1-22, Thumb screw 1-23 and Torx head 1-24.

[0061] The collet in this embodiment is connected with the collet driving mechanism, and the collet includes a male tongs 1-1 and a female tongs 1-2, a male tongs 1-1 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com