Instrument board structure for installing PAB without tubular beam

A technology for instrument panels and mounting holes, which is applied in the field of instrument panel structures where PAB is installed without pipe beams. It can solve the problems that the blasting load-bearing effect has not been disclosed, and achieve increased blasting load-bearing performance, wide application prospects, and exact fixing effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

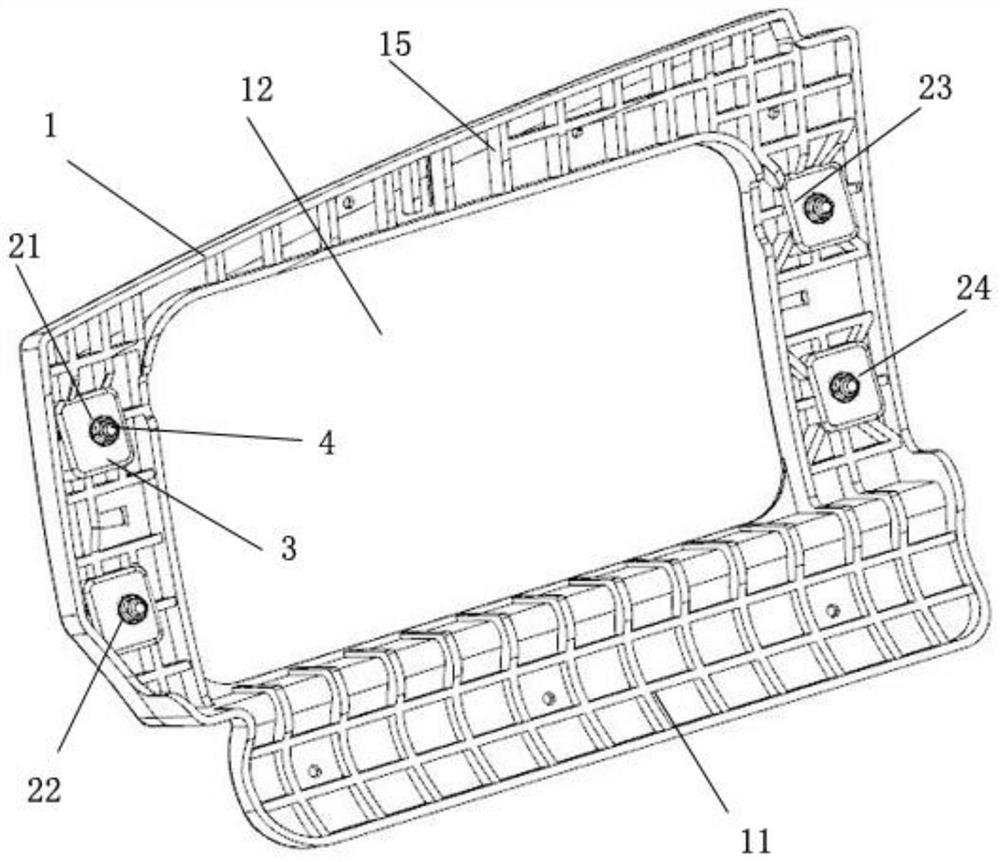

[0034] The reference signs and components involved in the accompanying drawings are as follows:

[0035] 1. Reinforcing plate 11. Rolling plate

[0036] 12. Mounting hole 13. Fixing hole

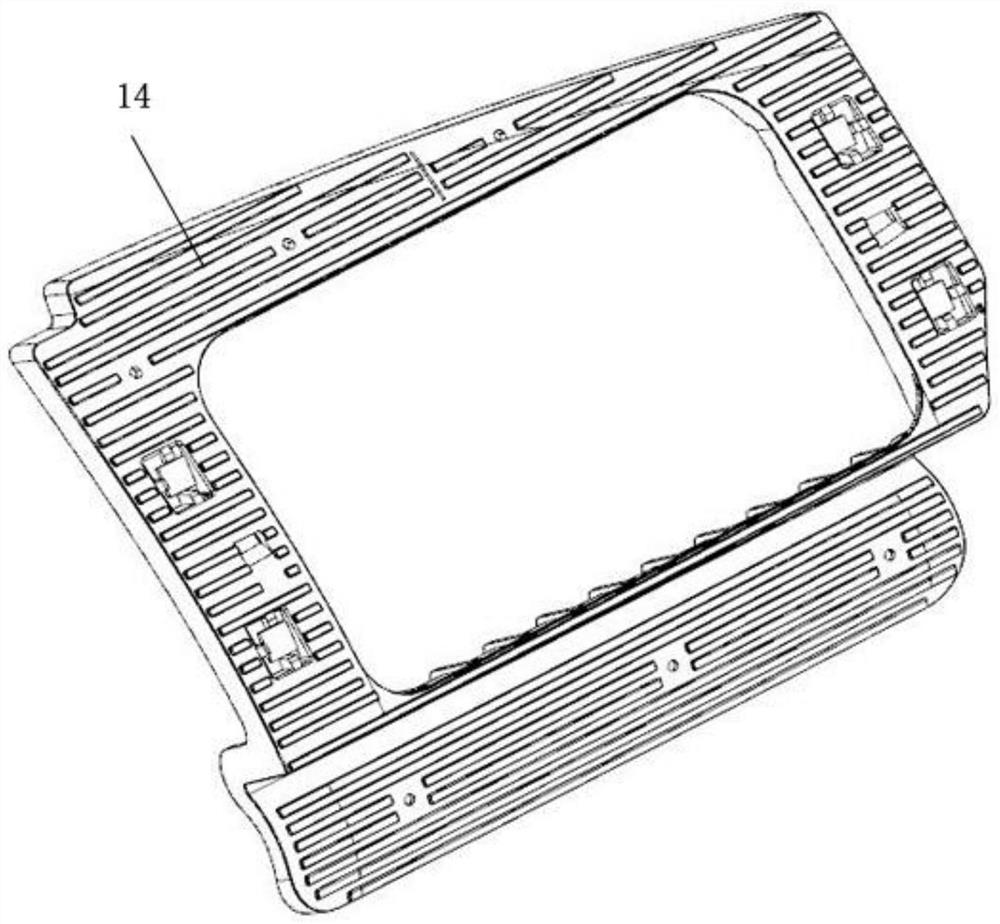

[0037] 131. Limiting strip 14. Welding rib

[0038] 15. Rib 2. Fixed components

[0039] 21. First fixing part 22. Second fixing part

[0040] 23. The third fixing part 24. The fourth fixing part

[0041] 3. Support platform 31. Extrusion block

[0042] 4. Fixing screw 5. Fixing lug

[0043] 51. PAB airbag module fixing part 52. Connecting part

[0044] 53. Reinforcing plate fixing part 531. First fixing piece

[0045] 532. Connecting piece 533. Second fixing piece

[0046] 54. Inner cavity 55. Reinforcing block

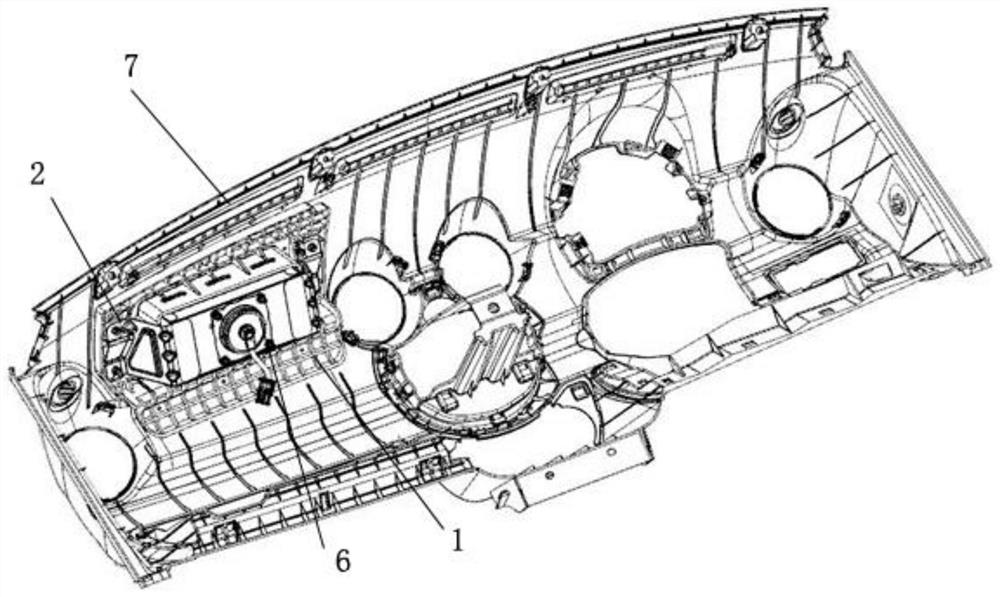

[0047] 6. PAB airbag module 7. Instrument panel body

[0048] Please refer to figure 1 , figure 1 It is a structural sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com