Flame-retardant carpet film, flame-retardant carpet and manufacturing method of flame-retardant carpet

A production method and carpet technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of poor flame retardancy, reduce the thickness of the cast film, and strengthen the extrusion processing performance , The effect of reducing the risk of property loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

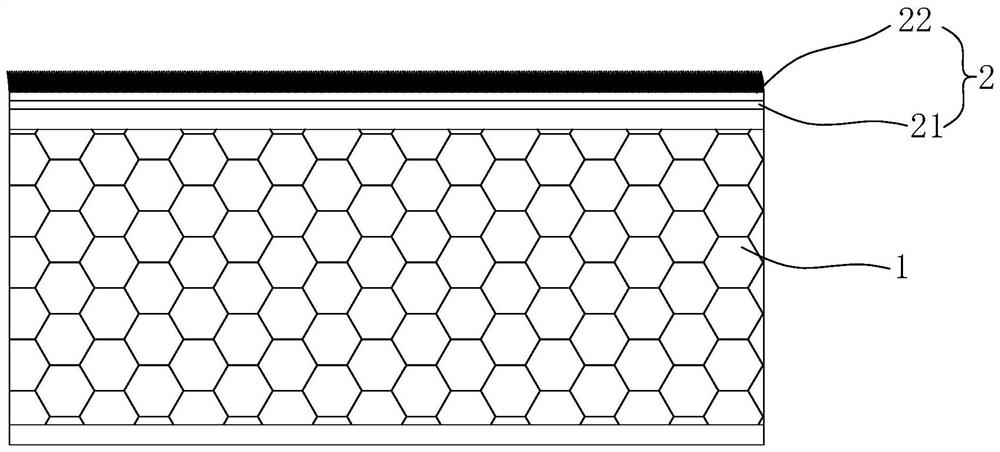

Image

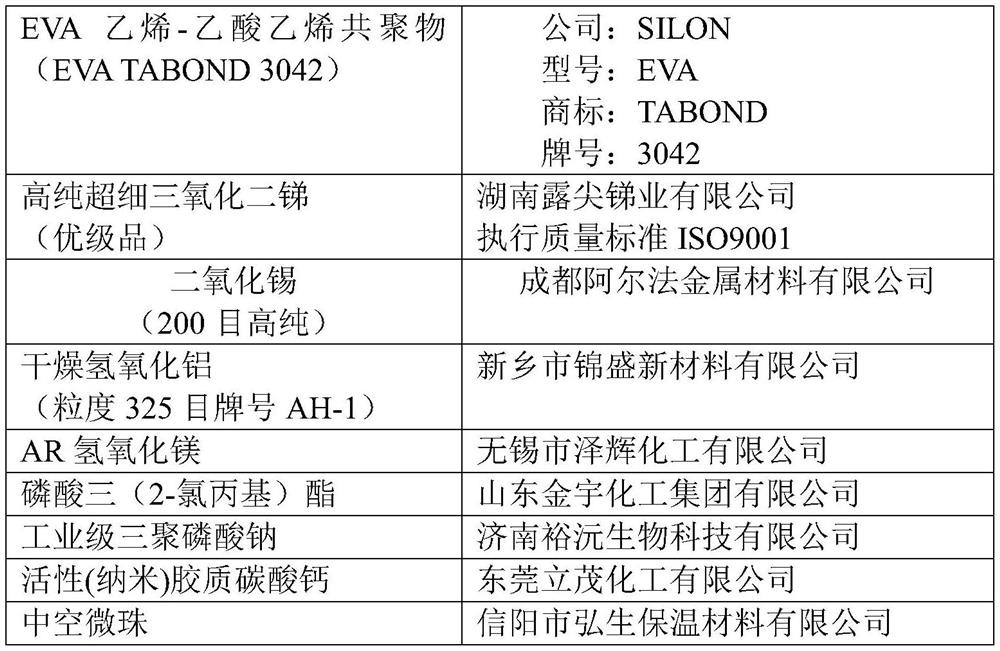

Examples

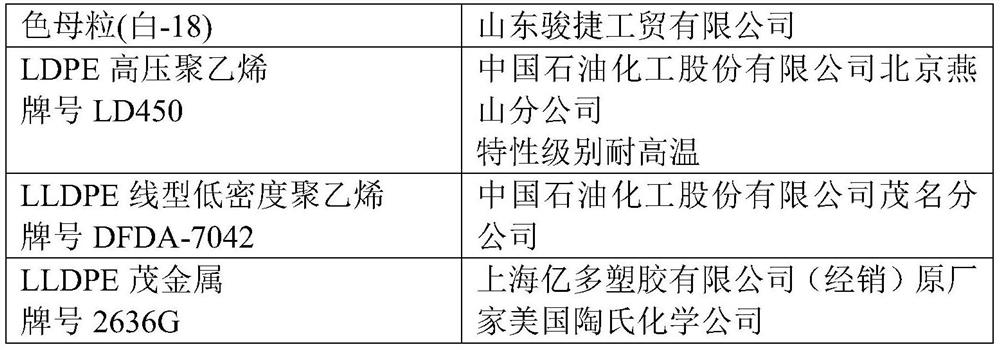

preparation example 1

[0038] LDPE high-pressure polyethylene is put into a twin-screw extruder at an extrusion temperature of 106°C, extruded, water-cooled, sent to a granulator for granulation, and pellets with a particle size of 0.5mm are obtained.

preparation example 2

[0040] LLDPE linear low-density polyethylene is put into a twin-screw extruder at an extrusion temperature of 117°C, extruded, water-cooled, sent to a granulator for granulation, and pellets with a particle size of 0.5mm are obtained.

preparation example 3

[0042]The LLDPE metallocene is put into a twin-screw extruder at an extrusion temperature of 105°C, extruded, cooled with water, sent to a granulator for granulation, and pellets with a particle size of 0.5mm are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com