Koji making device

A koji-making device and koji-making pool technology, applied in the field of food processing, can solve problems such as difficult control of feeding speed, unreasonable distribution of raw materials, and affecting production efficiency, so as to save labor force, increase the output of koji medicine, and have strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

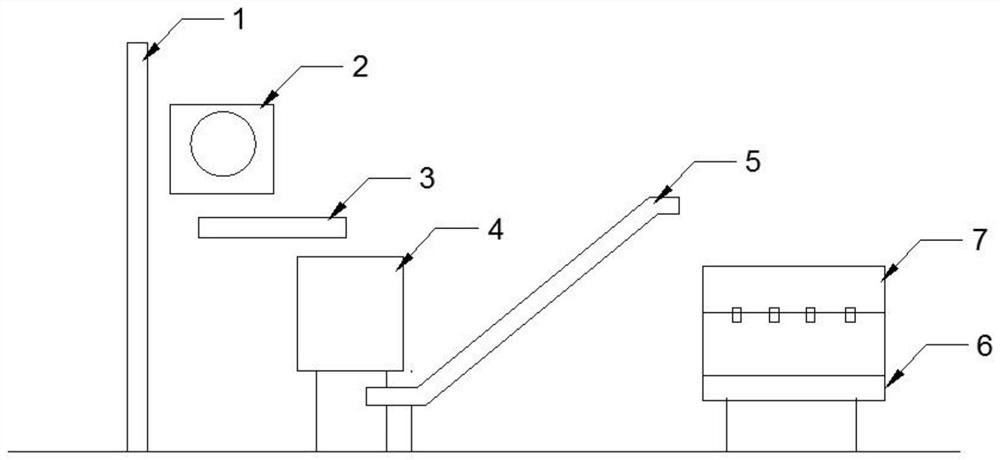

[0025] A koji making device, comprising a hoist, a crusher, a belt conveyor, a koji mixing machine, a conveyor belt, a koji making tank and a temperature measuring device;

[0026] The hoist is arranged on one side of the crusher, a belt conveyor is arranged below the crusher, a koji mixer is arranged downstream of the belt conveyor, a conveyor belt is arranged at the outlet of the koji mixer, and a koji pool is arranged below the end of the conveyor belt;

[0027] A detachable temperature measuring device is arranged above the koji making pool;

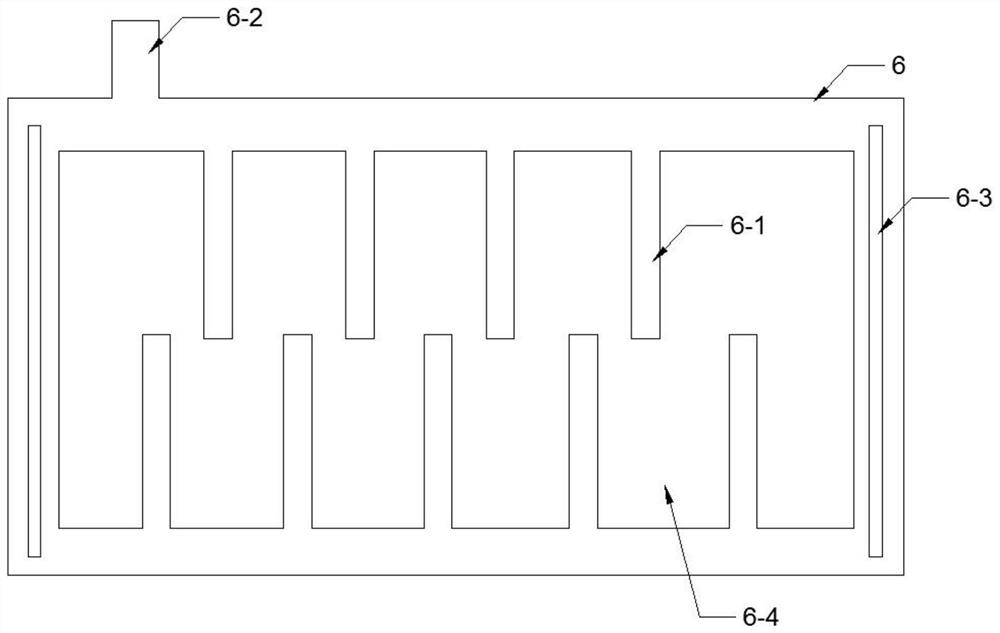

[0028] The interior of the koji-making pool is relatively intersected with partition plates, which form an S-shaped koji-making tank inside the koji-making pool. A liquid inlet pipe / outlet pipe is formed on one side of the Quchi pool wall; a chute is formed on the upper end surfaces of the pool walls on both sides of the Quchi pool;

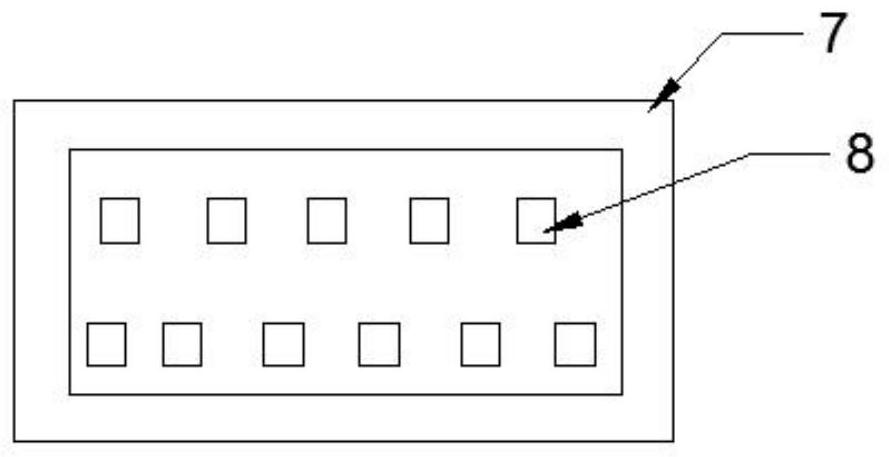

[0029] The temperature measuring device is in the shape of a cover, straddling the koji making pool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com