Manufacturing method of free-cutting warp knitted fabric based on RSJ warp knitting machine

A manufacturing method and technology of warp knitting machines, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of incomplete free cutting, easy detachment, and increased cost of RSJ fabrics, and achieve a balance between feel and cost. Contradictory, soft and comfortable feel, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0016] Embodiment 1 of the present invention adopts the wrapping yarn forming method containing dry-spun spandex, and its characteristics include:

[0017] 1. Synthesize a wrapped yarn containing dry-spun spandex instead of conventional loop-forming raw materials.

[0018] 2. Make the wrapping yarn raw material containing dry-spun spandex through a special warping method to make a warp beam with uniform draft ratio of single yarn.

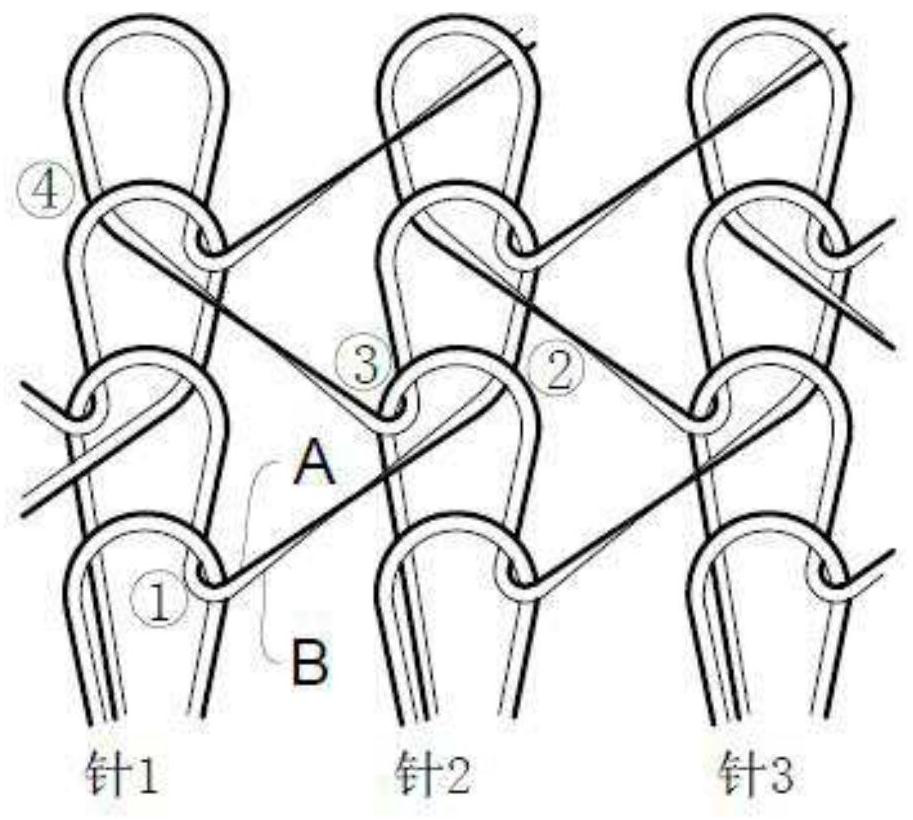

[0019] 3. Use the RSJ warp knitting machine to form a specific anti-loosening structure, that is, a warp yarn is alternately looped in multiple wales, and the loops are fully retracted and compacted in the warp and weft directions.

[0020] The present invention requires that the fabric courses can be tightly interwoven, and the dry-spun spandex wrapped yarn satisfies the requirement of the present invention well. Dry-spun spandex wrapping yarn uses super-elastic dry-spun spandex yarn as the yarn core, and is wrapped with a filament or short fiber...

Embodiment approach 2

[0026] Embodiment 2 of the present invention adopts the method of Jacquard double-threaded ultra-fine dry spinning naked ammonia and another kind of loop-forming raw material yarn to make a loop structure, and its technical characteristics include:

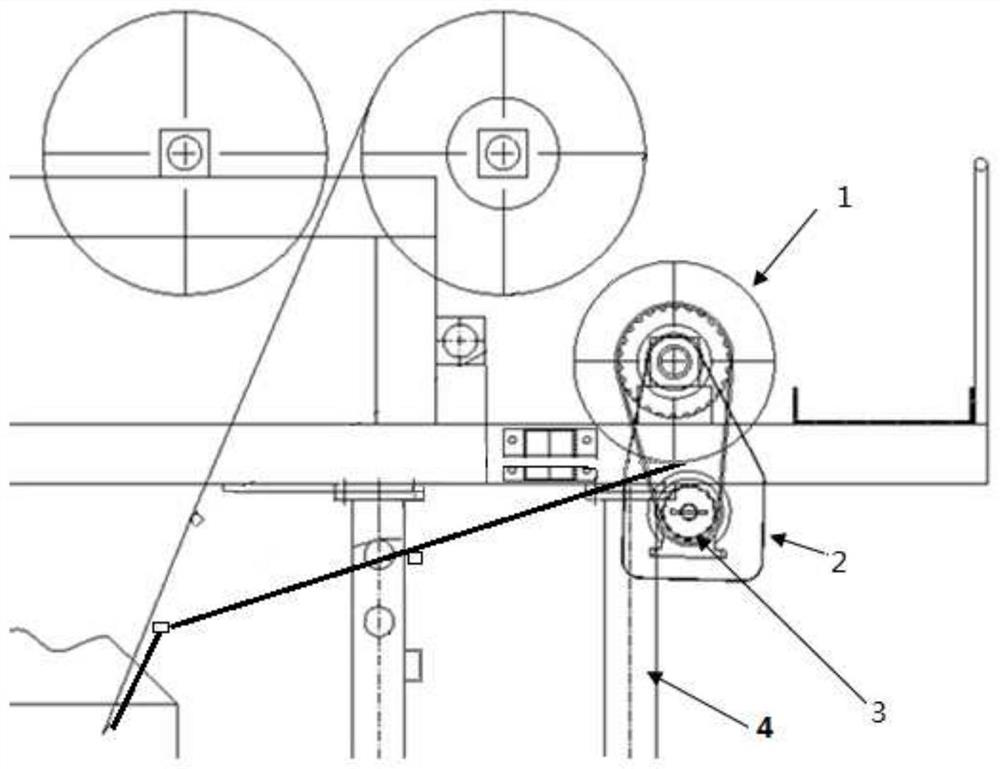

[0027] 1. On the basis of the original warp let-off of the RSJ warp knitting machine, another set of warp let-off is installed, which is located at the front end of the Jacquard warp let-off (not from the front and back of the two Jacquard combs according to the existing design). pinhole), which facilitates the elastic yarn to pass through the two jacquard guide pinholes from the front of the guide comb. The biggest advantage of threading yarn in this way is to fully consider the situation that the elastic yarn is prone to sticking and knotting during the starting process, and it is as convenient as possible for the staff to troubleshoot the yarn failure.

[0028] 2. A new set of independent yarn running system suitable for ultra-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com