Whole-course cold chain implementation method

A technology of whole-process cold chain and implementation method, applied in the field of whole-process cold chain, can solve the problems of quality decline of fresh agricultural products, unsuitable and unreasonable production mode, etc., and achieve the effect of moderate capacity, avoiding cooling loss and avoiding physical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

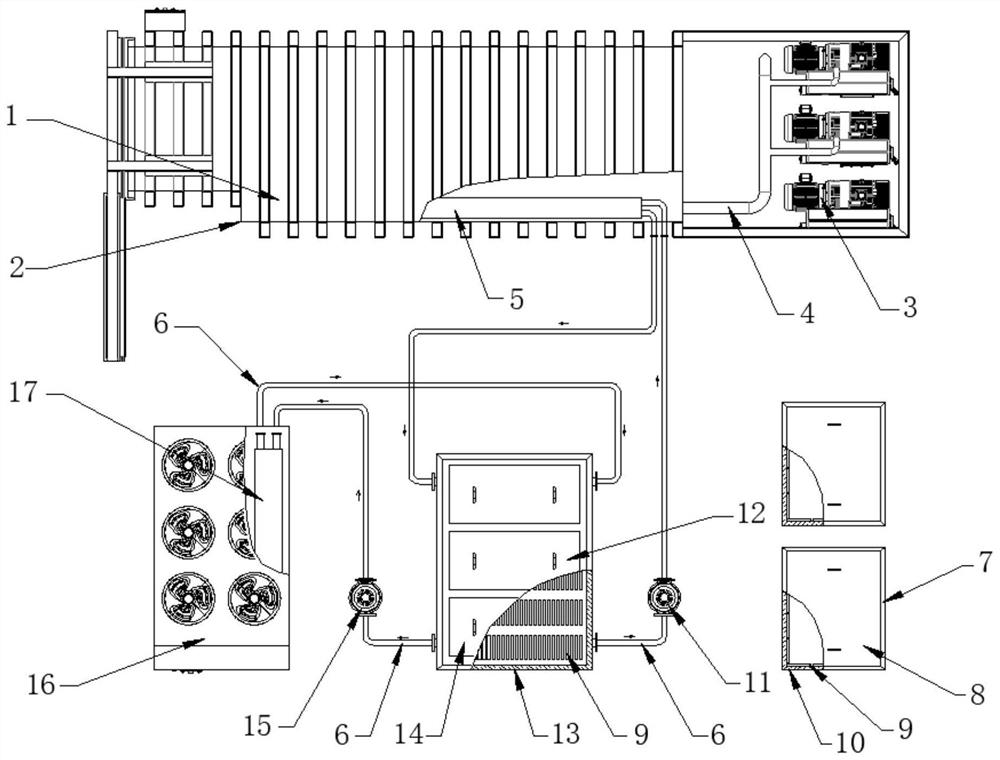

[0025] Such as figure 1 As shown, the present invention provides a new whole-process cold chain implementation method. The devices used in the implementation process include the following devices: phase change cold storage insulation box 7, vacuum rapid precooler 1, refrigeration unit 16, brine solution tank 12. The brine circulation pump a11 and the brine circulation pump b15; wherein, the phase change cold storage insulation box 7 includes a box insulation layer 10, an insulation box cover 8, a phase change cold storage plate 9 and a cold storage plate slot, and a cold storage plate card The groove is located inside the box insulation layer 10, and the phase change cold storage plate 9 can be easily inserted into the cold storage plate slot to fix it. The phase change cold storage plate 9 is filled with a phase change cold storage material, and the phase change cold storage temperature range of the phase change cold storage material is -5°C to 10°C; Vacuum fast pre-cooler 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com