A power-based online detection method for abnormal motion of industrial manipulators

A technology for industrial machinery and anomaly detection. It is used in machine gear/transmission mechanism testing, electrical power measurement, electrical measurement, etc. It can solve problems such as high cost, unreliable data, and noise interference, achieve good real-time response performance, reduce The probability of being tampered with and the effect of reducing the false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

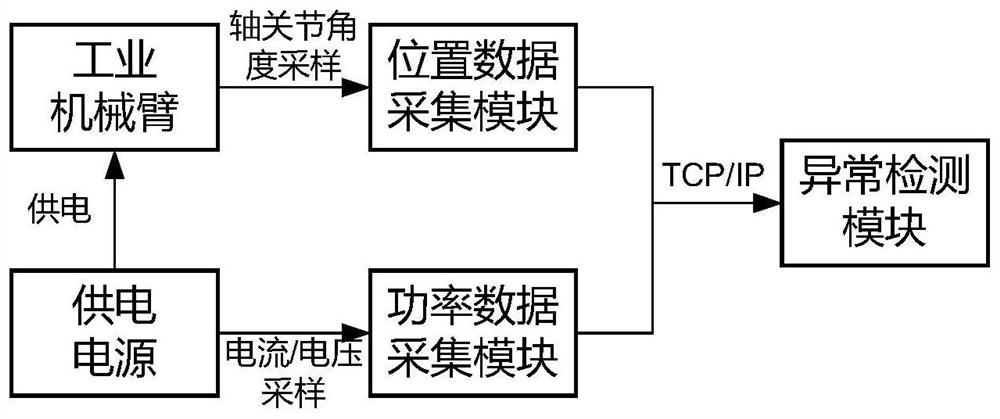

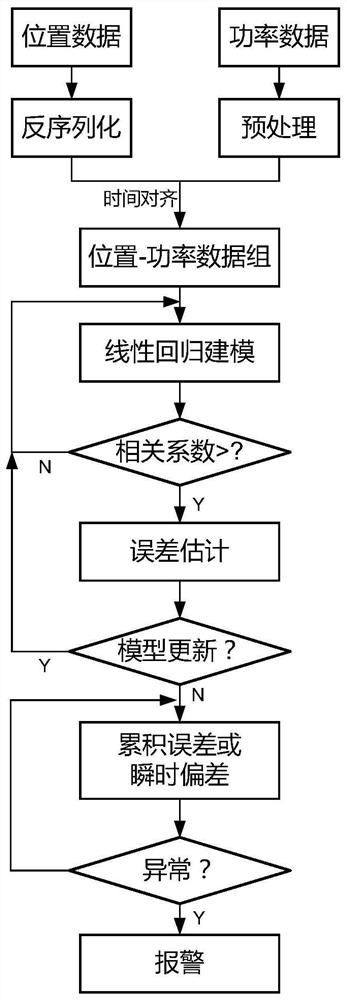

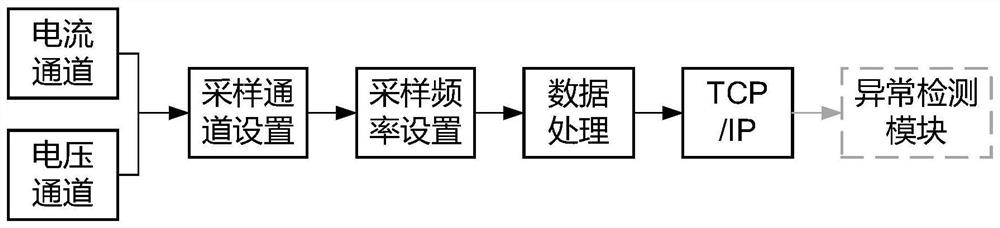

[0043] The power-based online detection method for abnormal motion of the industrial manipulator proposed by the present invention uses power and position asynchronous sampling data to solve time synchronization, and then identifies the dynamic model of the industrial manipulator through model parameter identification (for example, regression fitting can be used) The generalization parameters of , provide a basis for further judging the motion state of the manipulator through cumulative deviation or instantaneous deviation. The detection method proposed by the invention utilizes the characteristics of strongly correlated data to realize state verification, and provides a new idea for the problem of abnormal detection in an open environment.

[0044] The power-based online detection method for abnormal motion of industrial manipulator proposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com