Device and method for compensating wedge-shaped error in wafer bonding

A wedge-shaped error and wafer bonding technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the bonding accuracy error of the upper and lower wafers, the non-parallel of the upper and lower wafers, wedge error, etc. problem, to achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

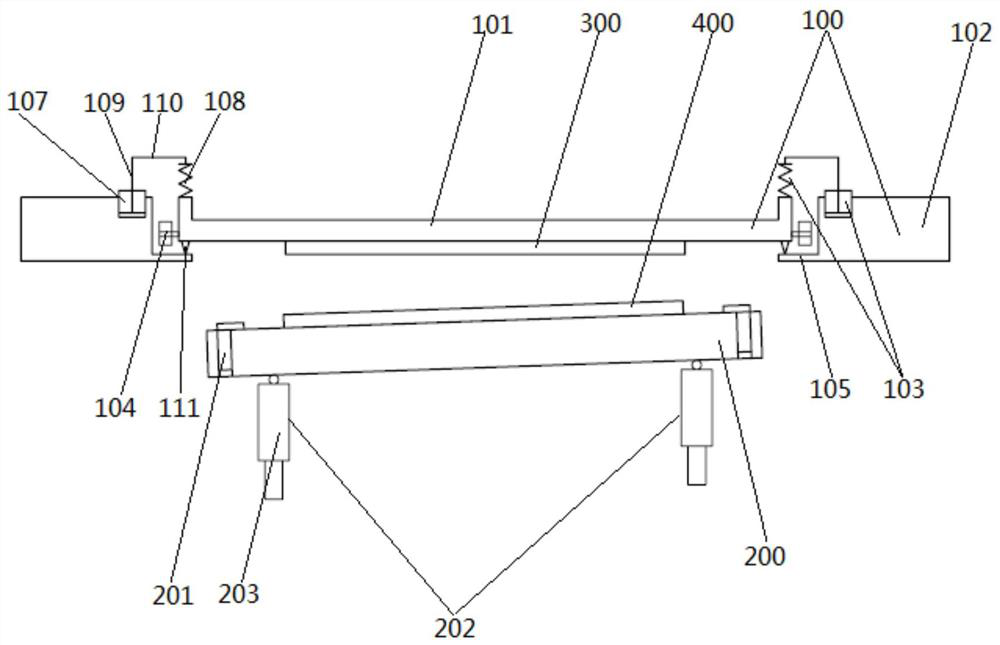

[0038] Embodiments of the present invention provide a device for compensating wedge errors in wafer bonding, such as figure 1 As shown, the device includes an upper loading platform 100 and a lower loading platform 200, wherein:

[0039] The lower platform 200 is provided with a first adsorption device, the upper surface of the lower platform 200 is provided with a gasket 201, the gasket 201 is connected with a gasket driving device, and the lower surface of the lower platform 200 is provided with a lifting and angle adjustment device 202.

[0040] The upper stage 100 includes an inner frame 101 and an outer frame 102. The edge area of the inner frame 101 is located above the outer frame 102. The inner frame 101 is floatingly connected to the outer frame 102 through a gravity balance device 103, so that the inner frame of the upper stage floats on the upper carrier. On the outer frame of the table, a plurality of capacitive sensors 104 are arranged on the edge area of the ...

Embodiment 2

[0055] An embodiment of the present invention provides a method for compensating wedge errors in wafer bonding, the method is based on the device for compensating wedge errors in wafer bonding described in Embodiment 1, and the method includes:

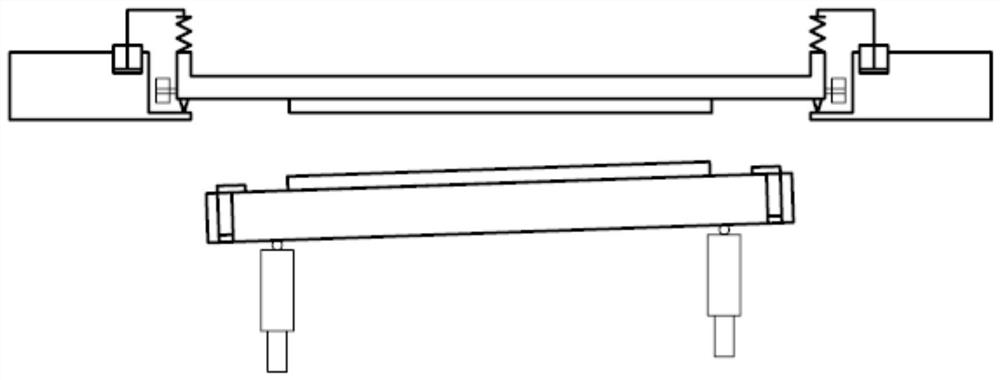

[0056] S1: The lower wafer is adsorbed on the upper surface of the lower carrier by the first adsorption device, and the upper wafer is adsorbed on the lower surface of the inner frame of the upper carrier by the second adsorption device, such as figure 2 shown.

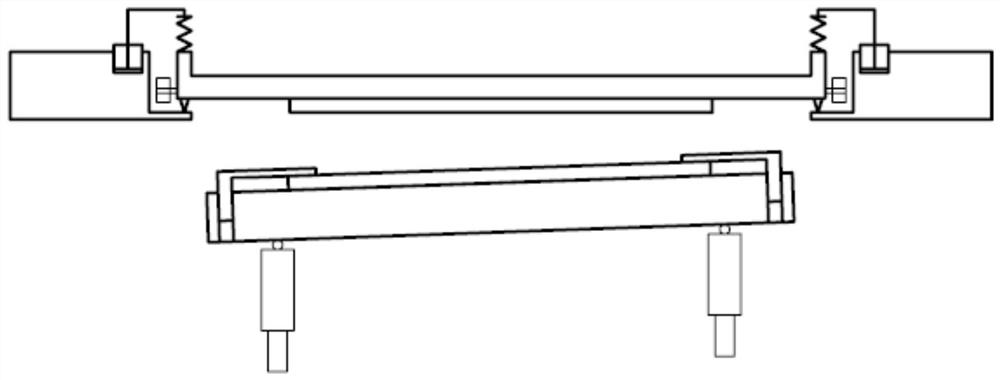

[0057] S2: The gasket on the lower carrier is pushed to the edge area of the upper surface of the lower wafer through the gasket driving device, such as image 3 shown.

[0058] S3: The gravity balance device performs gravity balance on the inner frame of the upper bearing platform, such as Figure 4 shown.

[0059] S4: The lower carrier is driven up by the lifting and angle adjustment device until it comes into contact with the upper wafer. The inner frame of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com