Double-specification moon cake mould

A dual-standard, moon cake technology, applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc., can solve problems such as inability to meet production needs, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

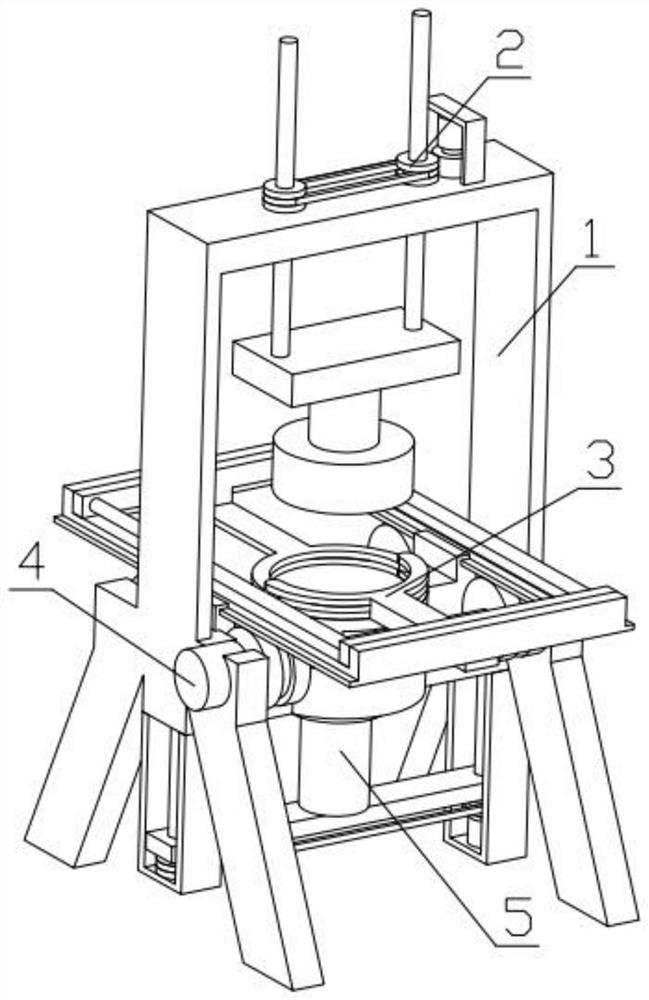

[0030] Combine below Figure 1-11 Describe this embodiment, a double-standard moon cake mold, including an assembly frame 1, a molding extrusion mechanism 2, a moon cake taking-out mechanism 3, a moon cake displacement mechanism 4 and a mold adjustment mechanism 5, and the molding extrusion mechanism 2 is fixedly installed in the assembly On the frame 1, the moon cake take-out mechanism 3 is slidingly installed in the groove provided on the assembly frame 1, the moon cake take-out mechanism 3 is engaged with the moon cake displacement mechanism 4, the moon cake displacement mechanism 4 is fixedly installed on the assembly frame 1, and the mold adjustment mechanism 5 is fixed Installed on the assembly frame 1.

specific Embodiment approach 2

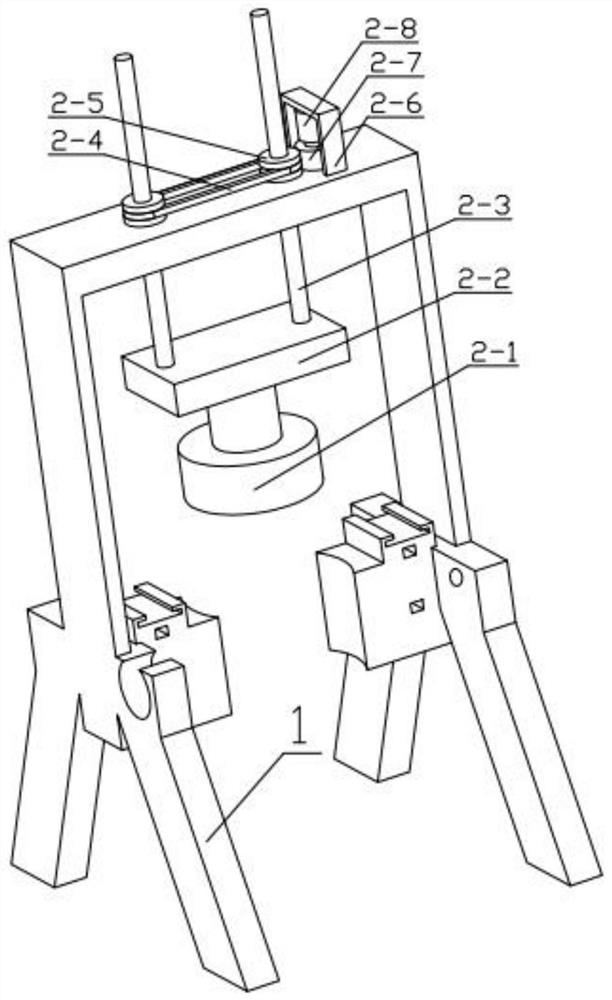

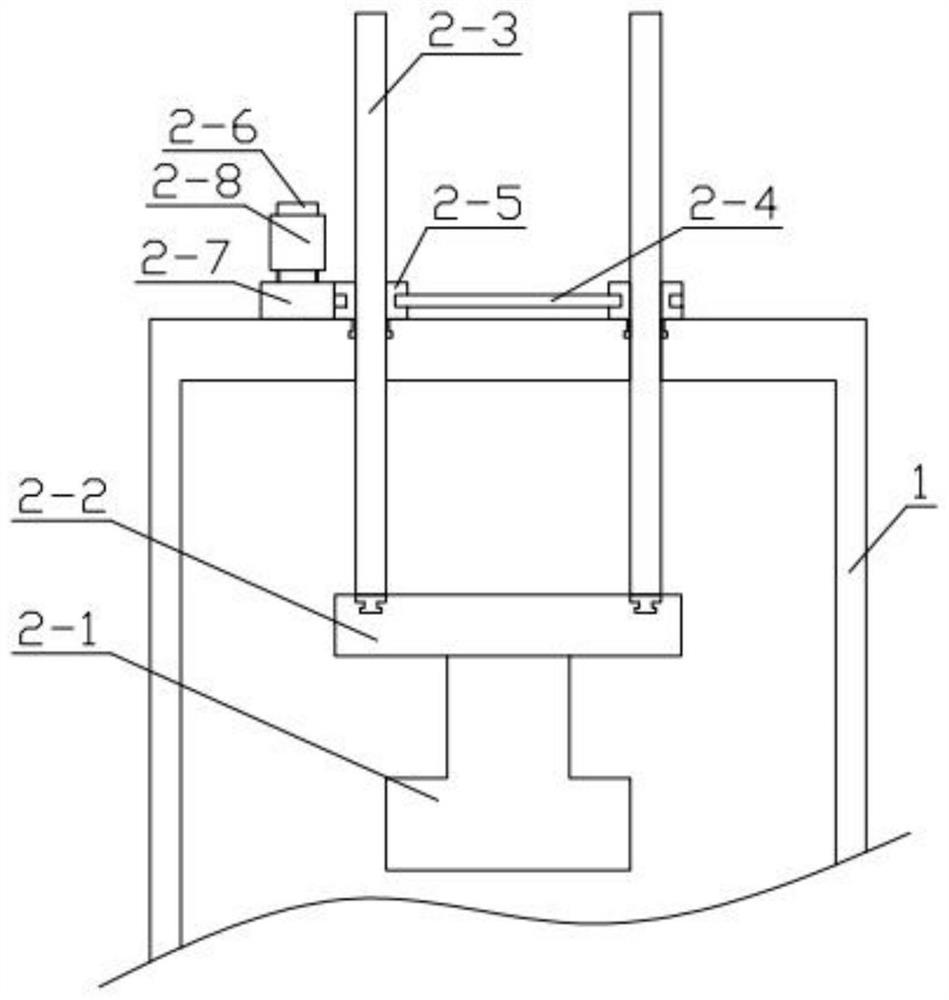

[0032] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the first embodiment, the forming extrusion mechanism 2 includes a circular extrusion part 2-1, a push plate 2-2, a threaded rod 2-3, and a synchronous chain 2-4 , limit sprocket 2-5, motor frame 2-6, motor gear 2-7, lifting motor 2-8, circular extruded part 2-1 is fixedly installed on the push plate 2-2, push plate 2-2 Threaded rods 2-3 are respectively rotated on both sides, threaded rods 2-3 pass through the assembly frame 1 and are threaded with the limit sprocket 2-5, and the limit sprocket 2-5 is rotatably installed on the assembly frame 1 In the groove, the limit sprocket 2-5 meshes with the synchronous chain 2-4, the limit sprocket 2-5 meshes with the motor gear 2-7, and the motor gear 2-7 is fixedly installed on the lifting motor 2-8 output end, the lifting motor 2-8 is fixedly mounted on the motor frame 2-6, and the motor frame 2-6 is fixedly mounted on the assembly fram...

specific Embodiment approach 3

[0034]Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain Embodiment 1, the described moon cake take-out mechanism 3 includes a square frame 3-1, clamping motor 3-2, two-way threaded rod one 3-3, two-way threaded rod two 3- 4. Clamp the inner rod 3-5, clamp the outer rod 3-6, the square frame 3-1 is slidably installed in the groove provided on the assembly frame 1, and the clamping motor 3-2 is fixedly installed on the square frame 3-1 Above, one end of the bidirectional threaded rod 3-3 is fixedly installed on the output end of the clamping motor 3-2, and the other end of the bidirectional threaded rod 3-3 is rotatably installed in the groove provided on the square frame 3-1, bidirectional Threaded rod one 3-3 is threadedly connected with clamping inner rod 3-5, two-way threaded rod one 3-3 is threadedly connected with clamping outer rod 3-6, and clamping outer rod 3-6 is slidably installed on two-way threaded rod two 3 -4, the gripping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com