Hollow brick dust removing device

A cleaning device and technology of hollow bricks, which are applied in the direction of dust removal, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as high resource utilization costs, incomplete cleaning, and impact on brick quality, and achieve high practicability and applicability, prevent dust from polluting the air, and reduce air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

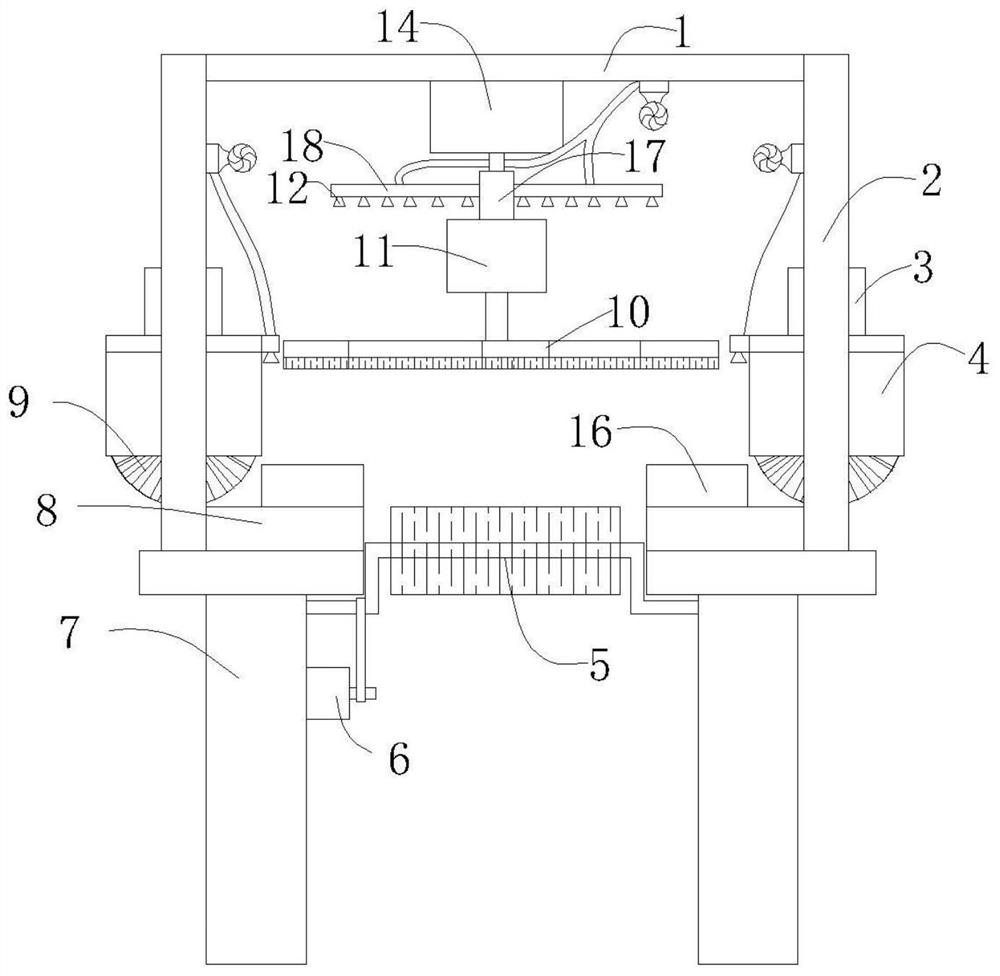

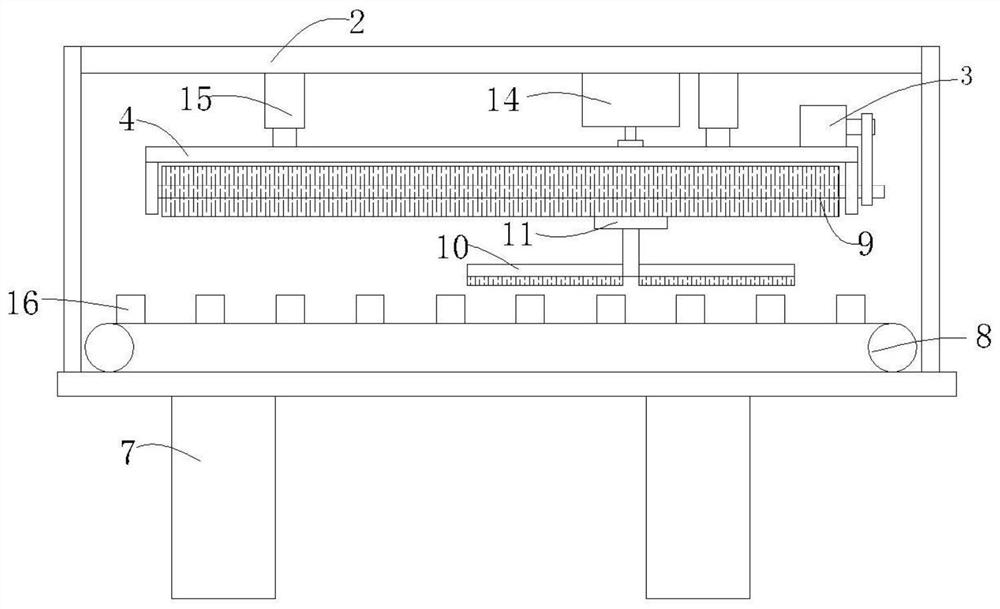

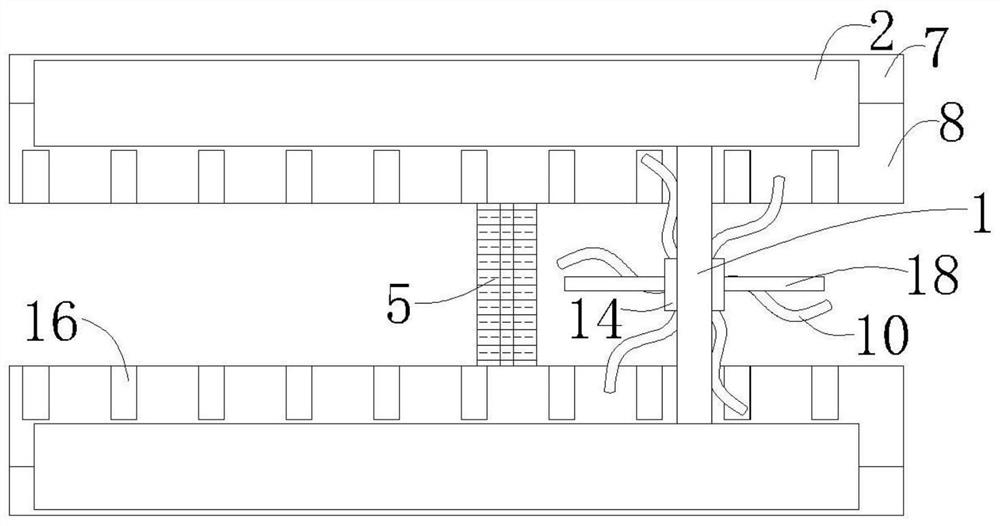

[0021] refer to figure 1 As shown, it is a schematic diagram of the side structure of a hollow brick dust cleaning device Figure 1 , a hollow brick cleaning device, including a support frame 7, a cleaning roller unit and two mutually parallel conveyor belts 8 arranged on the support frame 7, the two conveyor belts 8 rotate synchronously, and the conveyor belts 8 are distributed along the extension direction of the conveyor belt 8 Limiting block 16, the limiting block 16 on the two conveyor belts 8 coincides in the running direction perpendicular to the conveyor belt 8 all the time. Place the two ends of the bricks on the two conveyor belts 8 respectively, so that the bricks are located between the two corresponding limit blocks 16 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com