Machining tool for fixed pins of commercial vehicle fuel tank

A fixed pin and commercial vehicle technology, applied in the field of parts processing, can solve the problems of low processing efficiency, low production efficiency, and high labor costs, and achieve the effects of stable fixing effect, stable quality, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

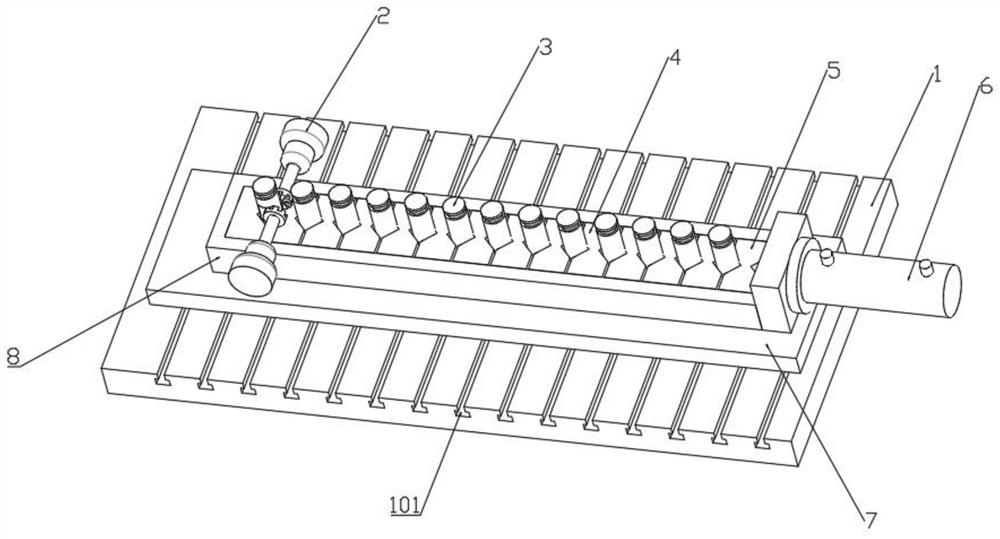

[0022] as attached figure 1 Shown:

[0023] The present invention provides a commercial vehicle fuel tank fixing pin processing tooling, comprising a milling machine tooling table 1, a milling machine double cutter head 2 and a product blank 3; the milling machine tooling table 1 is located at the bottom of a support plate 7; the milling machine double cutter head 2 is located in a product assembly groove 8; The lower end of the product blank 3 is located inside the V-shaped clamping block 4, and the V-shaped clamping block 4 is fixedly connected with the oil cylinder pressing block 5; the V-shaped clamping block 4 and the oil cylinder pressing block 5 are located inside the product assembly groove 8.

[0024] Among them, the top of the milling machine tooling table 1 is provided with multiple grooves 101, and the bottom of the support plate 7 is slidingly connected to the groove 101 on the top of the milling machine tooling table 1; The left and right distances determine the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap