Tunnel rail-mounted safety inspection robot and tunnel rail-mounted safety inspection robot system

An inspection robot and rail-type technology, which is applied in the field of tunnel rail-type safety inspection robots and their systems, can solve problems such as rail-type inspection robots that have no safety management application scenarios, and achieve lower implementation costs and lower costs. Maintenance costs, improve work efficiency, and achieve the effect of management automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically describe the tunnel rail safety inspection robot and its system of the present invention in conjunction with the accompanying drawings.

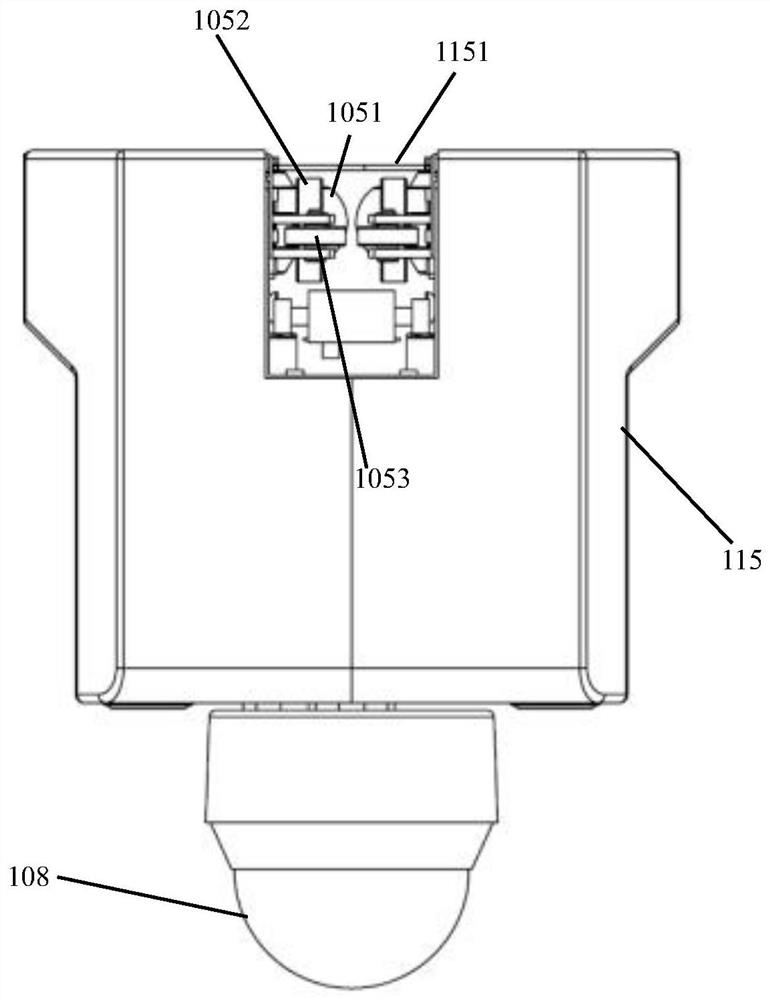

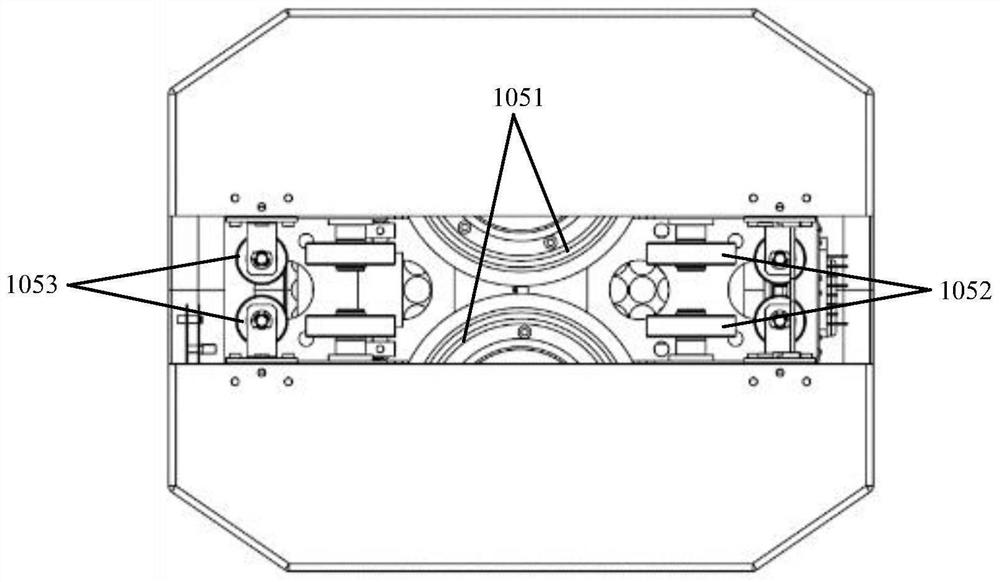

[0032] The tunnel rail safety inspection robot includes: a support (not shown in the figure), a track (not shown in the figure) and a plurality of inspection robots 100 . The bracket is fixed in the tunnel, the track is installed on the bracket, and each inspection robot 100 is installed on the track and can move along the track. Tracks are deployed according to site needs.

[0033] The track includes a plurality of track modules, and the track modules are assembled into a track. Such as image 3 As shown, the cross section of the track module is "I" shape. In this embodiment, the track module is a customized standardized assembled track. It is used to realize plug-and-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com