A steel-plastic combined concrete prefabricated component mold and demoulding method thereof

A prefabricated component and concrete technology, applied in the field of concrete molds, can solve the problems of increasing the cost of the mold, affecting the quality of the components, increasing the demoulding force, etc., and achieving the effects of easy release, low labor cost, and ensuring the quality of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

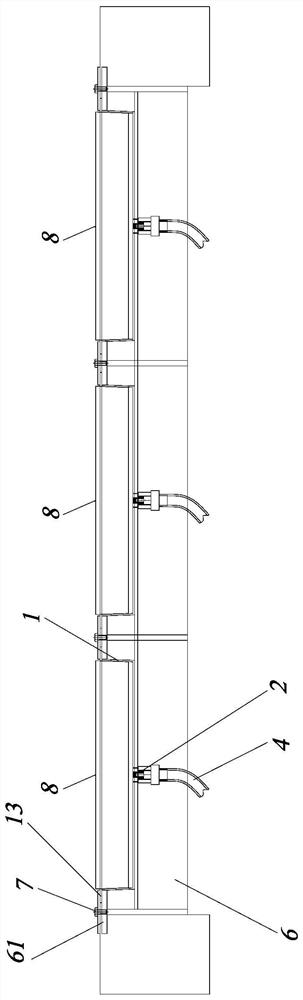

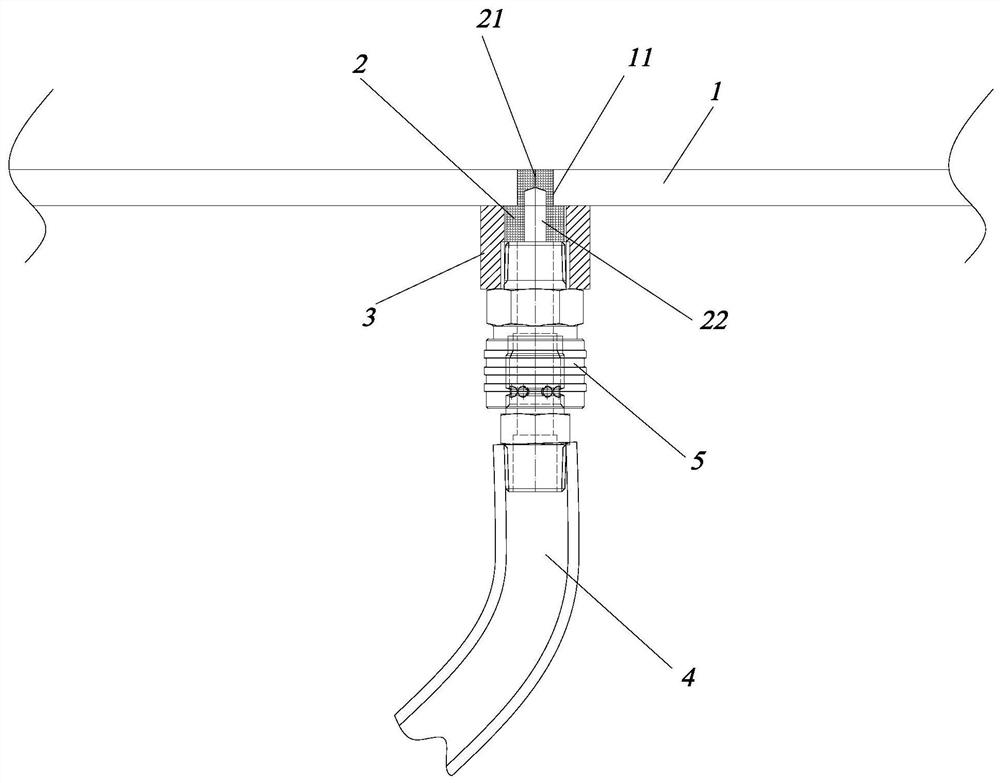

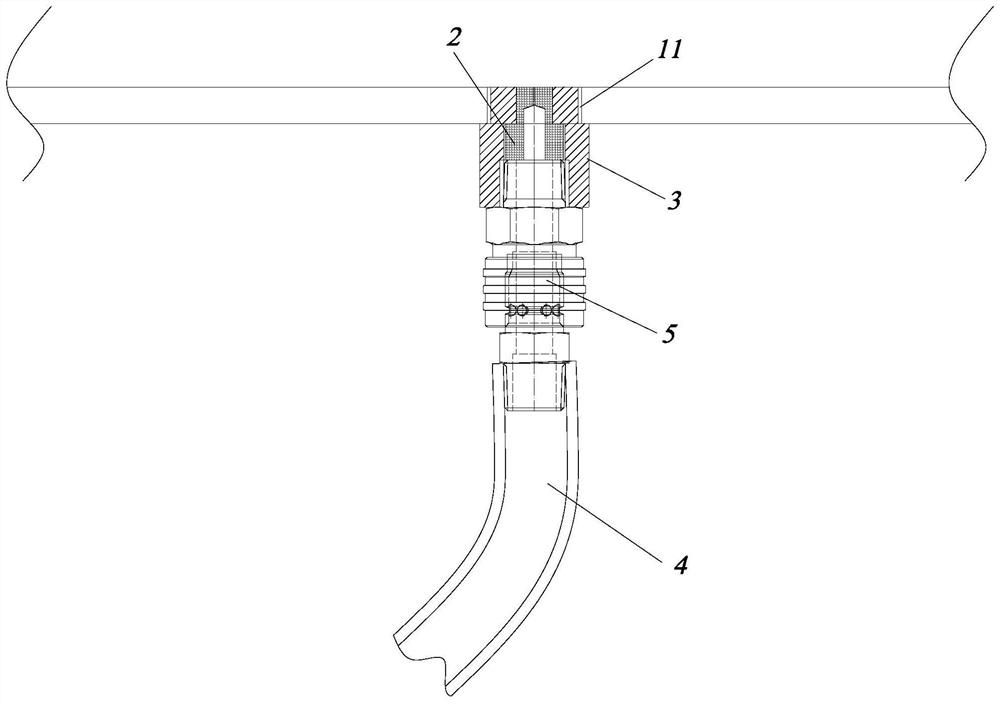

[0033] figure 1 , figure 2 and Figure 4 to Figure 7 An embodiment of the steel-plastic combined concrete prefabricated component mold of the present invention is shown. The steel-plastic combined concrete prefabricated component mold of this embodiment includes a plurality of plastic molds 1 and a steel frame 6 for supporting each plastic mold 1. , the plastic mold 1 includes a mold cavity 12 and a first connecting portion 13 arranged on the side of the mold cavity 12, a second connecting portion 61 is provided on the steel frame 6, and the first connecting portion 13 is fixedly connected with the second connecting portion 61 , each mold cavity 12 is provided with a mounting hole 11 and is equipped with an intake plug 2, one end of the intake plug 2 is provided with a first air intake portion 21 that can be opened and closed, and the other end is provided with a first air intake portion 21 The second air inlet portion 22 communicated with each other, the end of the air inl...

Embodiment 2

[0043] image 3 Another embodiment of the steel-plastic combined concrete prefabricated component mold of the present invention is shown. The steel-plastic combined concrete prefabricated component mold of this embodiment is basically the same in structure as the first embodiment, with the difference that: in this embodiment , the installation hole 11 is a threaded hole, and the air plug sleeve 3 is provided with an external thread and is arranged in the installation hole 11 through the external thread. Compared with the first embodiment, the threaded connection structure can facilitate the disassembly of the gas plug sleeve 3 .

Embodiment 3

[0045] like Figure 8 As shown, the demolding method based on the above-mentioned mold of the present embodiment comprises the following steps:

[0046] S1, the external gas or liquid enters the second air inlet portion 22 of the air inlet plug 2 and the first air inlet portion 21 is opened, and then the external gas or liquid enters the mold cavity 12 through the first air inlet portion 21;

[0047] S2. The vacuum suction cup 91 or the component clamp 92 on the component hanger 9 fixes the component 8, and then the component hanger 9 rises to lift the component 8 out of the mold cavity 12;

[0048] S3. The component hanger 9 transfers the component 8 to the stacking position, and the vacuum suction cup 91 or the component clamp 92 releases the component 8 to complete the stacking.

[0049] In this demolding method, the air inlet plug 2 is first ventilated (or liquid such as water is introduced) to increase the pressure in the mold cavity 12, so that after the component 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com