A locking gas outlet device for plexiglass potting

A technology of plexiglass and gas outlet device, which is applied in the field of plexiglass processing and molding, which can solve the problems of affecting the quality of finished products and easy generation of air bubbles, and achieve the effect of avoiding excessive outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

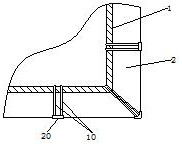

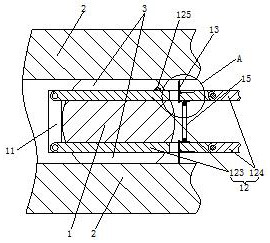

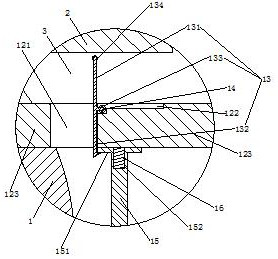

[0028] Such as Figure 1-Figure 5 As shown, a lock and air outlet device for plexiglass potting described in this embodiment includes a lock part 10 socketed with the sealing ring 1 and a buckle part 20 buckled on the glass plate 2; the lock part 10 includes The connecting rod 11 and two cross bars 12, the two cross bars 12 are respectively connected to the two ends of the connecting rod 11 in rotation, the connecting rod 11 is arranged on the side of the sealing ring 1 away from the buckle 20, the cross bar 12 A through groove 121 is provided, and the through groove 121 is arranged on the side of the cross bar 12 away from the connecting rod 11, and a rotating plate 13 is arranged in the through groove 121, and the rotating plate 13 includes an impact part arranged on the outside of the through groove 121 131. The buckle part 132 arranged inside the through groove 121 and the rotating part 133 arranged between the impact part 131 and the buckle part 132, the rotating part 133...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com