Jacking equipment for bridge construction

A technology for bridge construction and jacking, which is applied in bridge construction, bridge erection/assembly bridge, etc. It can solve problems such as bridge collapse, increased compressive stress of box-type bridges, and damage to the lower part of the bridge body, so as to prevent excessive pressure, The effect of increasing the pressure buffer and improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

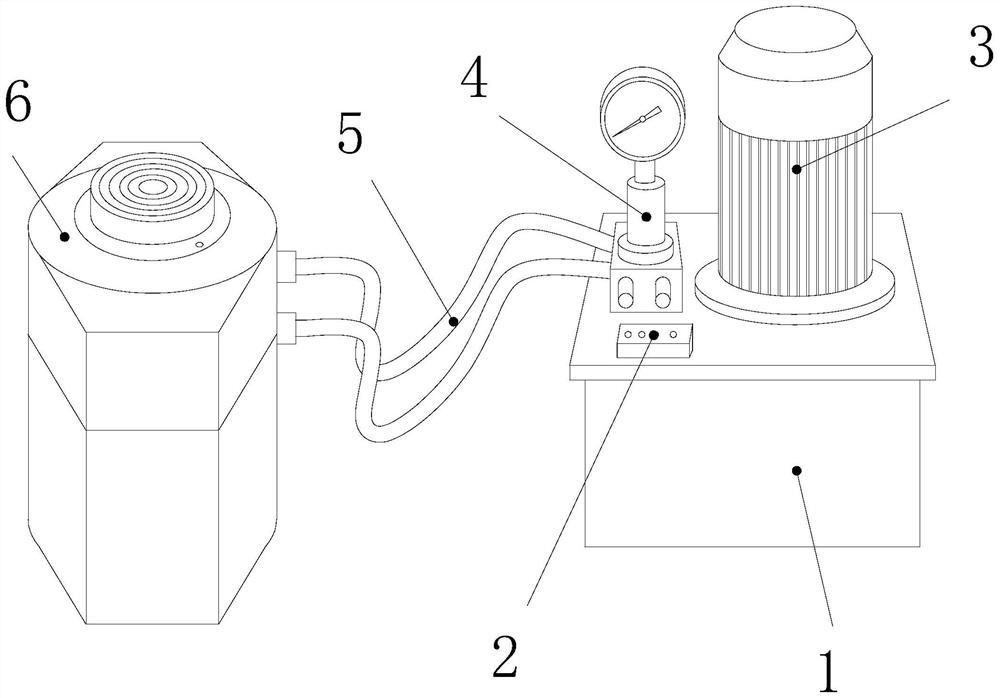

[0026] as attached figure 1 To attach Figure 5 Shown:

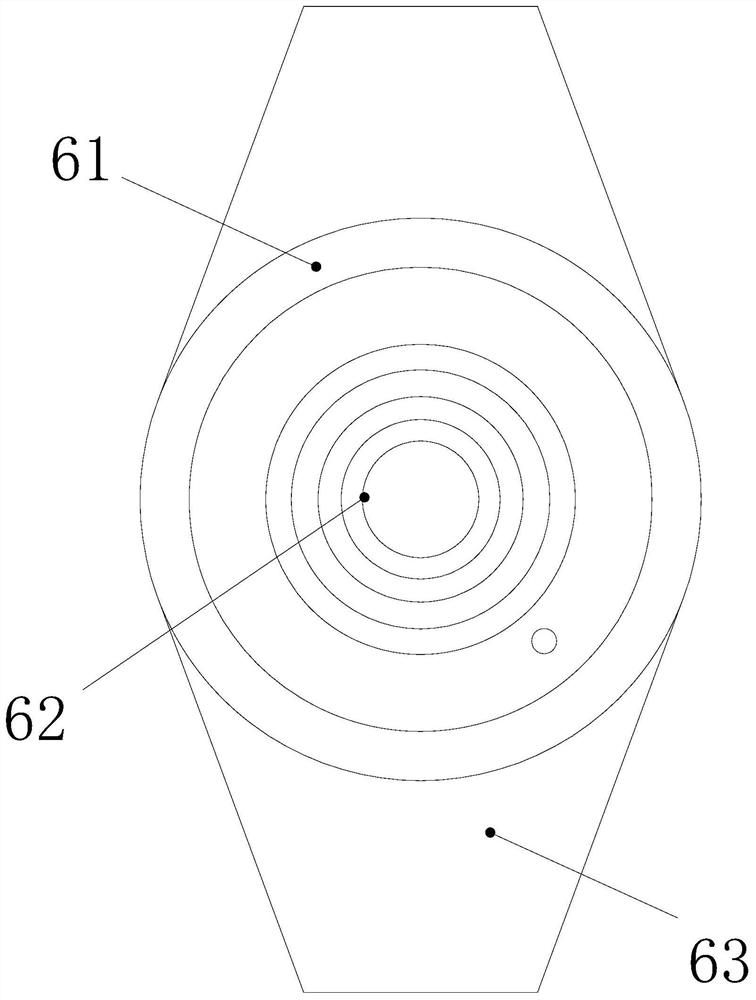

[0027] The invention provides a jacking device for bridge construction, the structure of which includes a base 1, a switch 2, an oil pump 3, a pressure gauge 4, a liquid supply pipe 5, and a jacking device 6, the upper side of the front end of the base 1 and the lower side of the switch 2 Embedded connection, the oil pump 3 is bolted to the upper side of the middle part of the base 1, the pressure gauge 4 is embedded and connected to the upper left end of the base 1, and the liquid supply pipe 5 is connected between the pressure gauge 4 and the jack 6 , the jacking device 6 is located on the left side of the base 1, the jacking device 6 includes an outer ring 61, a jacking rod 62, and an auxiliary device 63, and the right side of the outer ring 61 is screwed to the liquid supply pipe 5, and the The jacking rod 62 fits with the inner clearance of the outer ring 61, and the auxiliary device 63 is welded to the outer side...

Embodiment 2

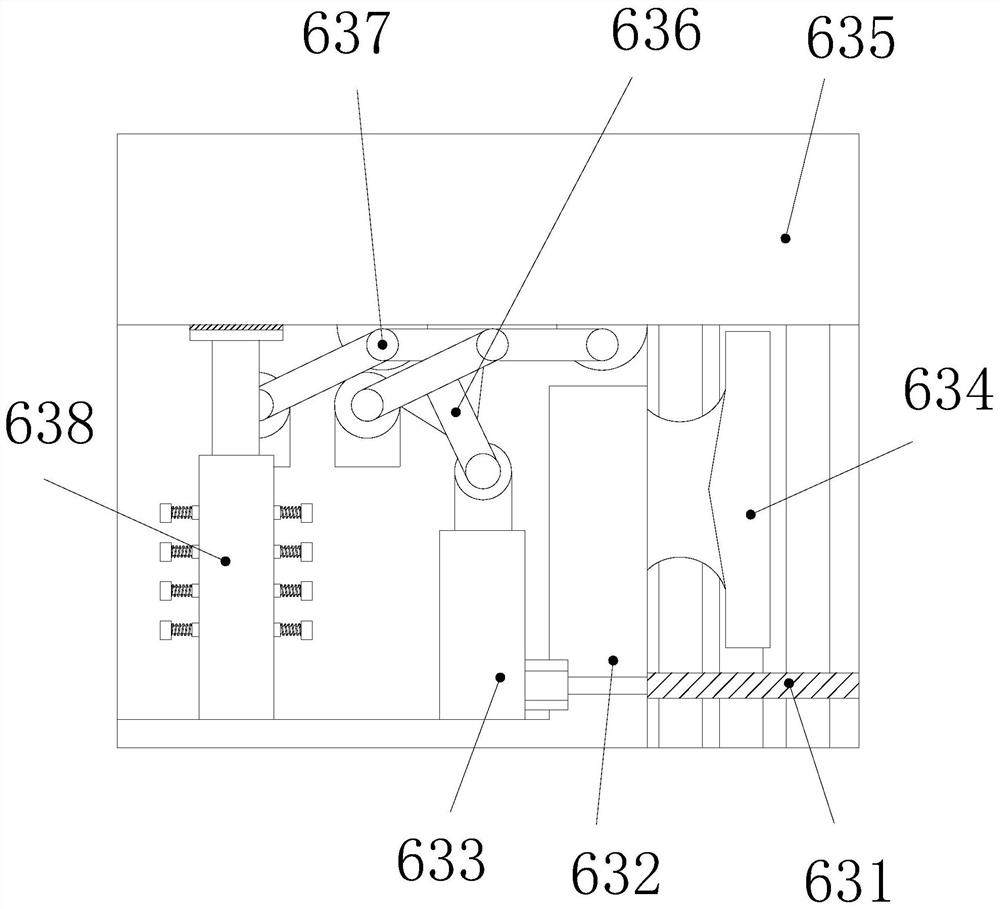

[0034] as attached Image 6 to attach Figure 8 Shown:

[0035] Wherein, the top pressing block 635 includes an upper abutment layer 35a, a tight structure 35b, a buffer block 35c, and a support block 35d, and the upper abutment layer 35a is connected with the support block 35d through a tight structure 35b, and the buffer block 35c Located between the support block 35d and the upper layer 35a, one end of the support block 35d is movably engaged with the engaging device 638, and the other end is axially connected to the upper side of the horizontal rod 637, and the upper layer 35a is in contact with the support block 35d The end is wave-shaped, and the upper layer 35a and the support block 35d form a mutual fit shape, so that the upper layer 35a and the support block 35d can be bonded according to the shape of the wave, which is conducive to improving the relationship between the upper layer 35a and the support block 35d. support between.

[0036] Wherein, the tension struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com