Elevator framework and corridor structure and installation method thereof

A technology for skeletons and corridors, which is applied to elevators, transportation and packaging, and building construction in buildings. It can solve problems such as low connection accuracy, low construction efficiency, and low structural strength, and achieve high support reliability and improved The effect of bearing capacity and the stability of the connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

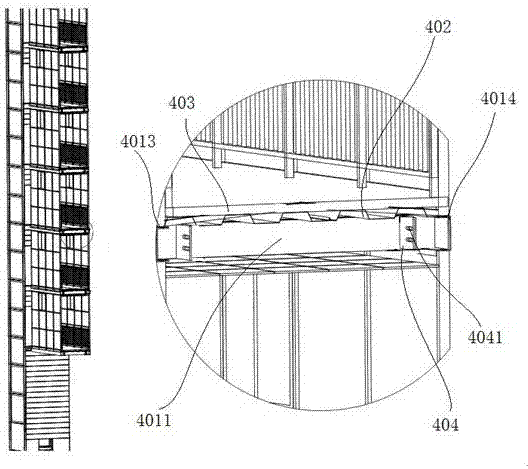

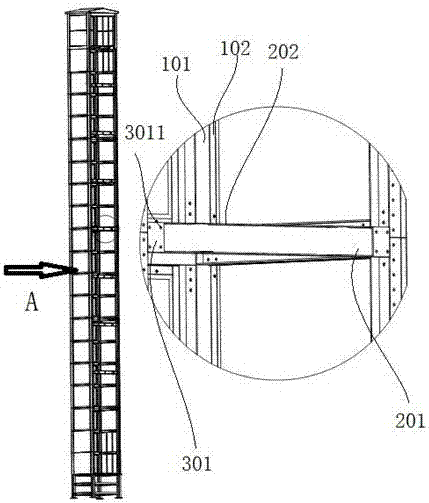

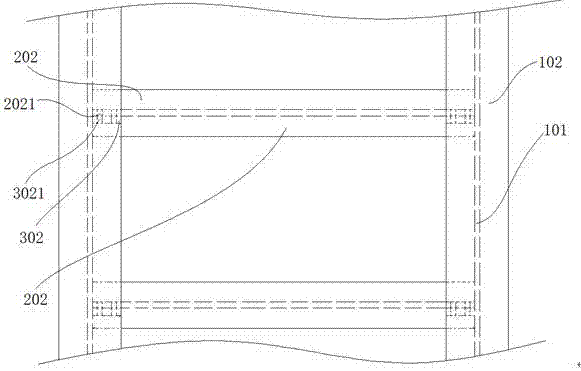

[0046] Such as Figure 1-5 As shown, this embodiment provides an elevator frame and corridor structure, including: elevator frame: including longitudinal H-shaped steel and transverse H-shaped steel, the longitudinal H-shaped steel includes a longitudinal web 101 and two longitudinal wings 102 parallel to each other, two A longitudinal web 102 is connected by a longitudinal web 101, and the longitudinal web 101 is vertically arranged between two longitudinal webs 102; the transverse H-shaped steel includes a transverse web 201 and two transverse webs 202 parallel to each other, and the two transverse Flanges 202 are connected by transverse webs 201, and transverse webs 201 are vertically arranged between two transverse webs 202, and transverse webs 201 are provided with web through holes; mounting plate: includes wing plate mounting plate 301 and web installation Plate 302, the wing plate mounting plate 301 is vertically connected to the outer surface of the longitudinal wing ...

Embodiment 2

[0056] This embodiment provides an elevator frame and corridor structure, including: elevator frame: including longitudinal H-shaped steel and transverse H-shaped steel, the longitudinal H-shaped steel includes a longitudinal web 101 and two longitudinal wing plates 102 parallel to each other, and two longitudinal wing plates The plates 102 are connected by a longitudinal web 101, which is vertically arranged between two longitudinal wings 102; the transverse H-shaped steel includes a transverse web 201 and two parallel transverse wings 202, and the two transverse wings 202 Connected by a transverse web 201, the transverse web 201 is vertically arranged between two transverse wing plates 202, and the transverse web 201 is provided with a web through hole; the mounting plate: includes a wing plate mounting plate 301 and a web mounting plate 302, The wing plate mounting plate 301 is vertically connected to the outer side of the longitudinal wing plate 102, and the wing plate moun...

Embodiment 3

[0058]This embodiment provides an elevator frame and corridor structure, including: elevator frame: including longitudinal H-shaped steel and transverse H-shaped steel, the longitudinal H-shaped steel includes a longitudinal web 101 and two longitudinal wing plates 102 parallel to each other, and two longitudinal wing plates The plates 102 are connected by a longitudinal web 101, which is vertically arranged between two longitudinal wings 102; the transverse H-shaped steel includes a transverse web 201 and two parallel transverse wings 202, and the two transverse wings 202 Connected by a transverse web 201, the transverse web 201 is vertically arranged between two transverse wing plates 202, and the transverse web 201 is provided with a web through hole; the mounting plate: includes a wing plate mounting plate 301 and a web mounting plate 302, The wing plate mounting plate 301 is vertically connected to the outer side of the longitudinal wing plate 102, and the wing plate mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com