Textile steam treatment equipment with recovery function

A processing equipment and textile technology, which is applied to the configuration of textile material equipment, spray/jet textile material processing, textiles and papermaking, etc., can solve the problems of resource waste, dampness, rough textile fabrics, etc., to improve the treatment effect and avoid dampness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

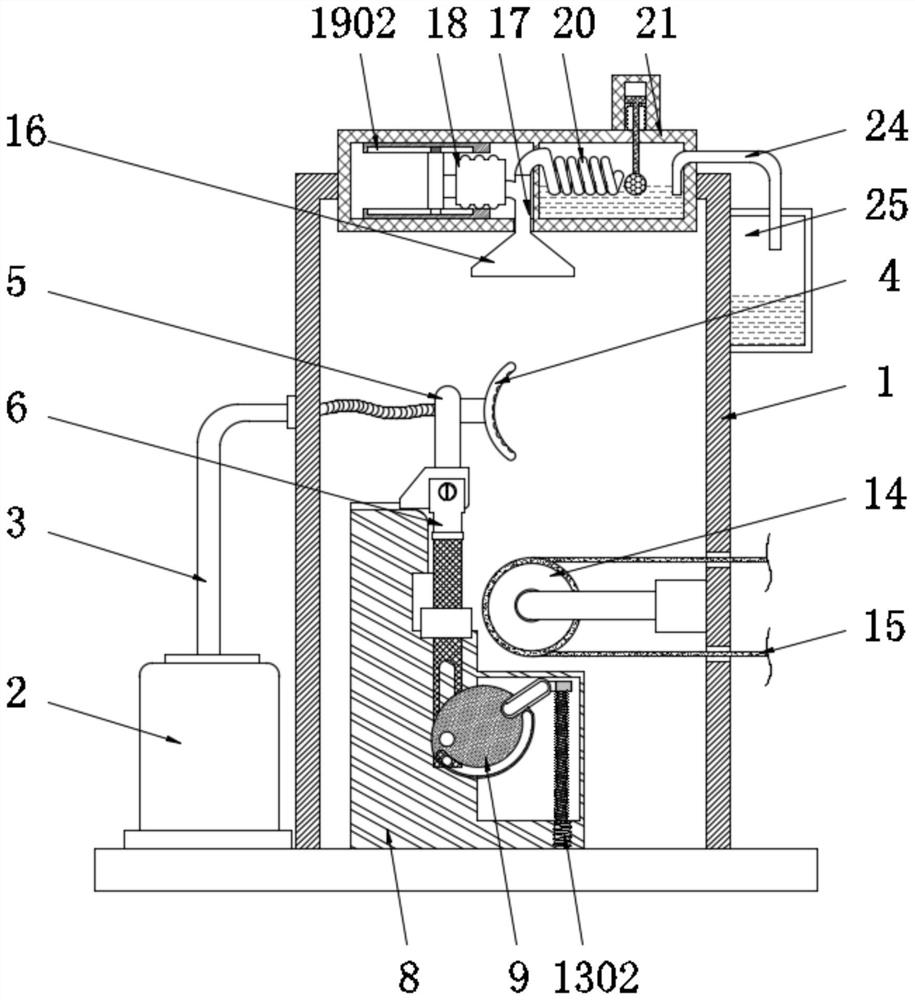

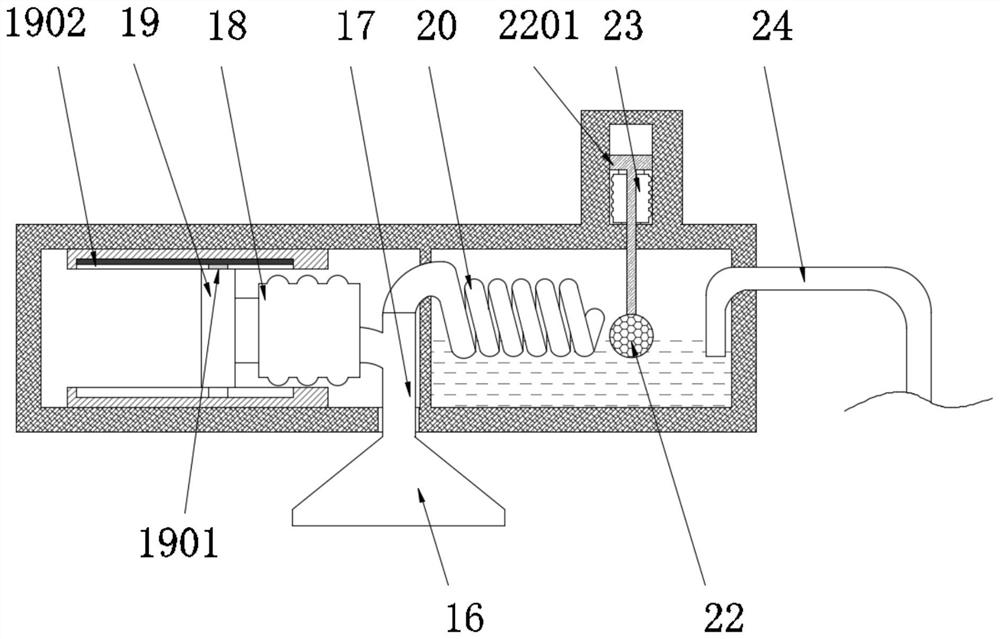

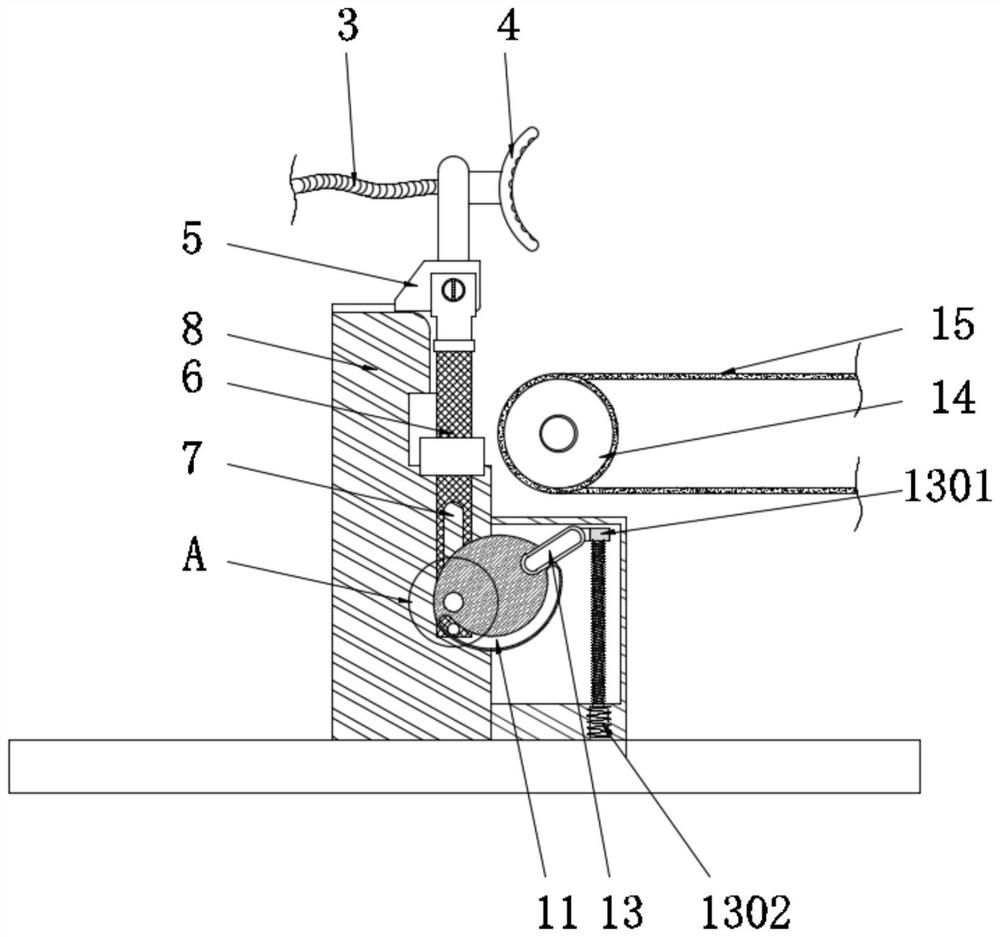

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] The invention provides a kind of textile steam treatment equipment with recovery function, as attached figure 1 to attach Figure 5 Shown: including processing chamber 1, steam tank 2 is fixedly installed on the left side of processing chamber 1, hose 3 is fixedly connected to the upper surface of steam tank 2, hose 3 runs through the left surface of processing chamber 1, and hose 3 runs through The inside of the adjustment head 5 is fixedly connected to the left surface of the steam nozzle 4, and the right end of the hose 3 is fixedly connected to the steam nozzle 4, which is a semi-arc structure. The semi-arc design of the steam nozzle 4 facilitates the weaving of textiles. 15 is processed between the steam nozzle 4 and the sticking roller 14, the steam nozzle 4 is fixedly installed on the right surface of the adjustment head 5, the adjustment head 5 is movably in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com