Labyrinth sealing device capable of reducing gap leakage flow

A technology of leakage flow and clearance, applied in the field of grate sealing device, can solve the problems of reducing engine life, causing danger, increasing leakage, etc., to reduce leakage flow, avoid leakage flow increase, and improve sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

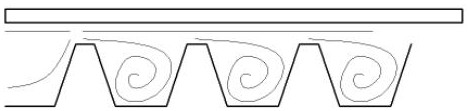

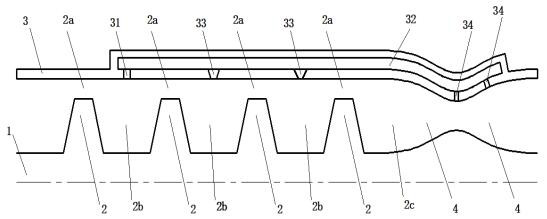

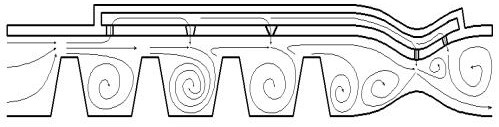

[0024] A grate tooth sealing device for reducing gap leakage flow in this embodiment includes a built-in rotating part 1, and a plurality of axially arranged sealing grate teeth 2 are arranged on the rotating part 1, while the rotating part 1 is equipped with The sealing bush 3, the outer peripheral surface of the sealing grate tooth 2 is matched with the inner ring surface of the sealing bush 3, so that the tip gap 2a is formed between the tip of the sealing grate tooth 2 and the inner ring surface of the sealing bush 3 , a tooth cavity 2b is formed between the adjacent sealing grate teeth 2, the sealing bush 3 cooperates with the rotating part 1 at the tail to form a tapered and expanded channel 4, and a transition section 2c is formed between the tapered and expanded channel 4 and the grate teeth , wherein: the grate tooth sealing device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com