Ignition resistor capable of enhancing firepower and manufacturing method thereof

A technology of ignition resistance and production method, which is applied to weapon accessories, offensive equipment, blasting tubes, etc., can solve the problems of insufficient contact surface, insufficient ignition ability of the resistance alloy layer, and failure to detonate, so as to avoid ignition failure, reliably detonate detonators, reduce The effect of rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

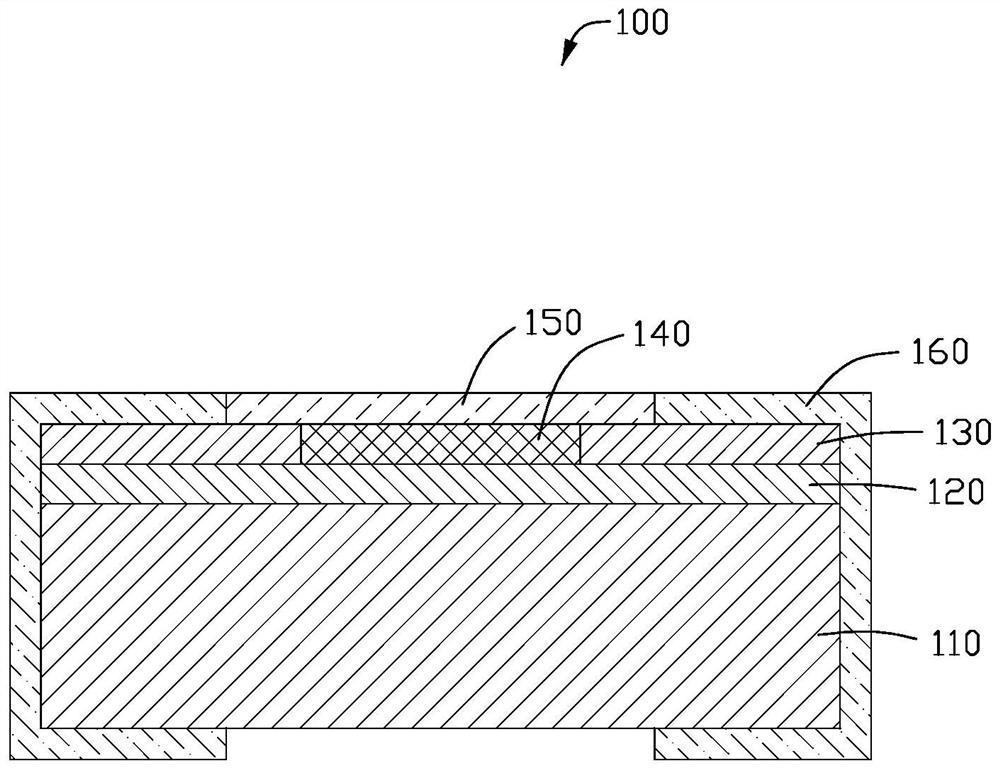

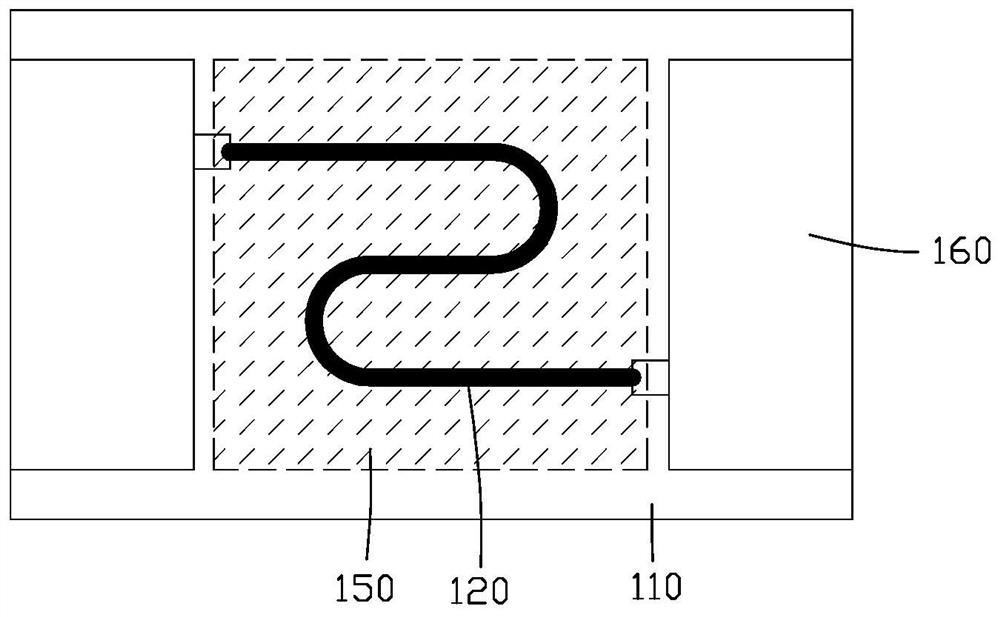

[0024] Such as figure 1 As shown, this embodiment provides an ignition resistor 100 that can enhance firepower. The resistor 100 includes a substrate 110, a resistance layer 120, a connection layer 130, an insulating layer 140, a metal combustion-supporting layer 150, and an electrode layer 160. The resistance layer 120 is located above the substrate 110, the metal combustion-supporting layer 150 is located above the resistance layer 120 and separated by the insulating layer 140, and the connecting layer 130 is located on the insulating layer 140. on both sides of the resistance layer 120, the electrode layer 160 is located on both sides of the metal combustion-supporting layer 150 and above the connection layer 130, the electrode layer 160 is connected from the connection layer 130 The upper surface extends toward the side of the substrate 110 and the back of the substrate 110, and the connection layer 130 connects the resistance layer 120 to the side electrodes and then to t...

no. 2 approach

[0038] The technical solution of the first implementation manner may be correspondingly applicable to this implementation manner, which will not be repeated here.

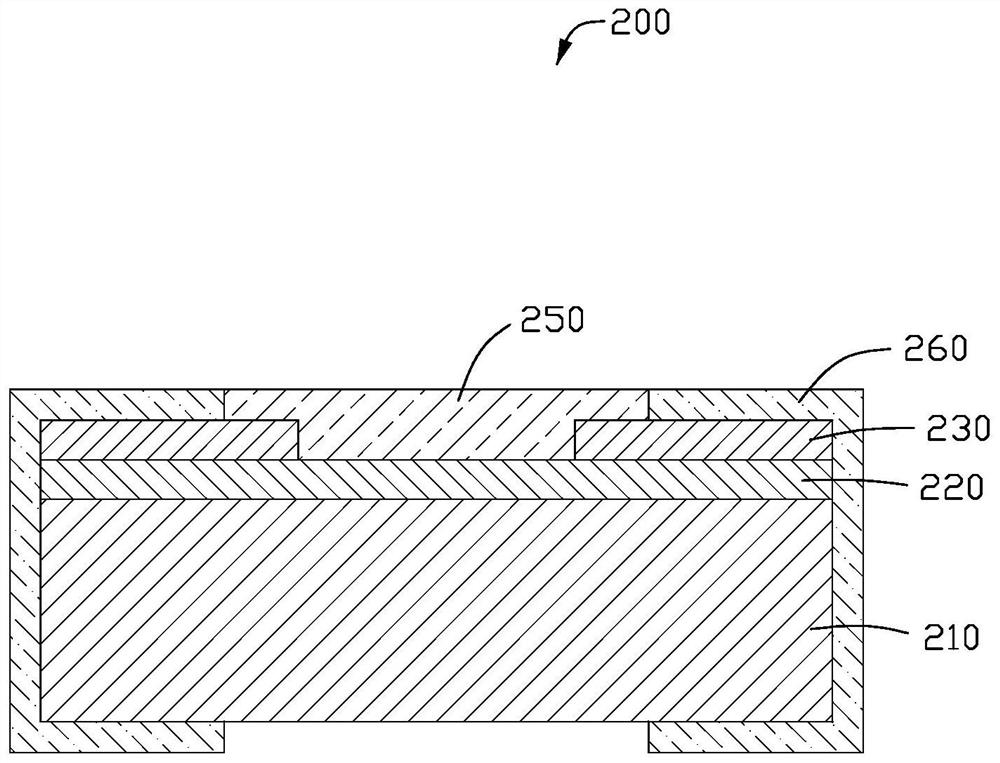

[0039] Such as image 3 As shown, this embodiment provides an ignition resistor 200 that can enhance firepower. The resistor 200 includes a substrate 210, a resistance layer 220, a connection layer 230, a metal combustion-supporting layer 250, and an electrode layer 260. The resistance layer 220 Located above the substrate 210, the metal combustion-supporting layer 250 is in direct contact with the resistance layer 220, the connection layer 230 is located on both sides of the metal combustion-supporting layer 250 and above the resistance layer 220, the The electrode layer 260 is located on both sides of the metal combustion-supporting layer 250 and above the connection layer 230 , and the electrode layer 260 extends from the upper surface of the connection layer 230 to the side of the substrate 210 and the Extendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com