Power plant blower fault early warning method based on multivariate state estimation

A technology of fault early warning and multi-state, which is applied in the direction of measuring electricity, measuring electrical variables, and testing of machine/structural components, etc. It can solve problems such as large fault early warning, low model applicability, and low learning rate, so as to ensure accuracy , Improve the operation speed, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

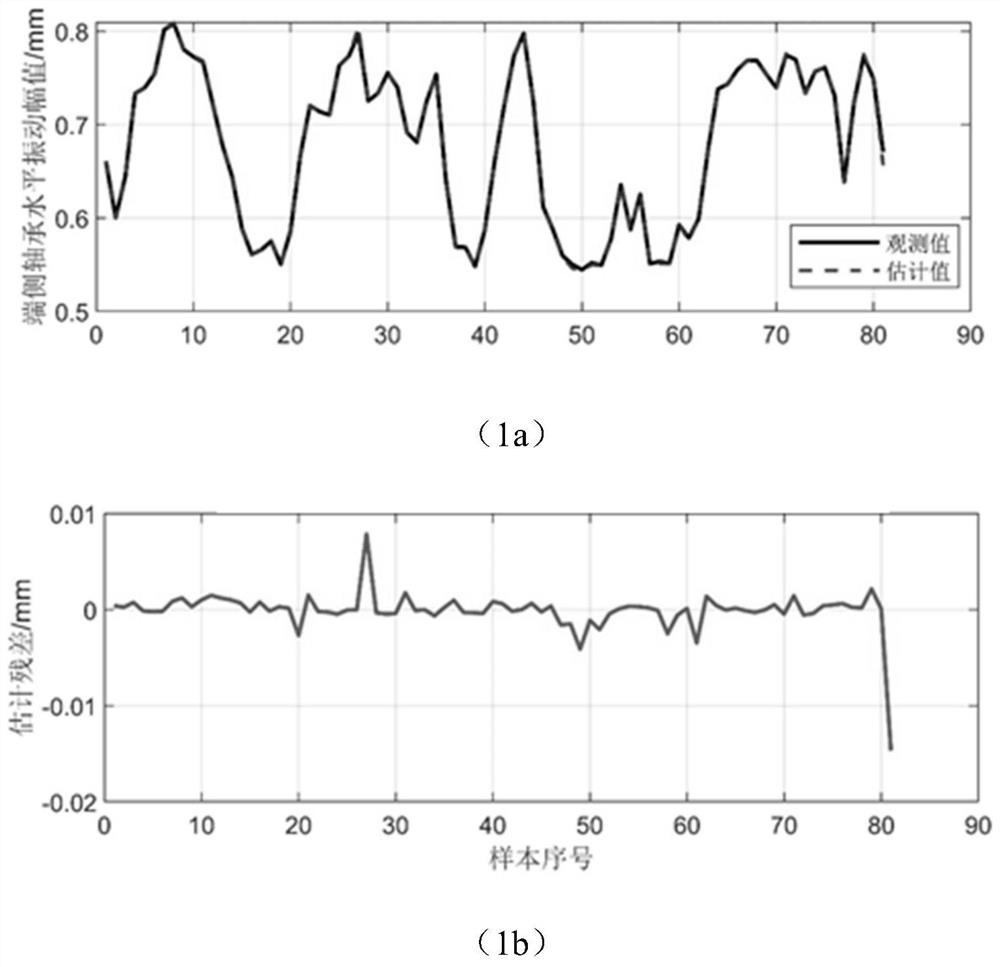

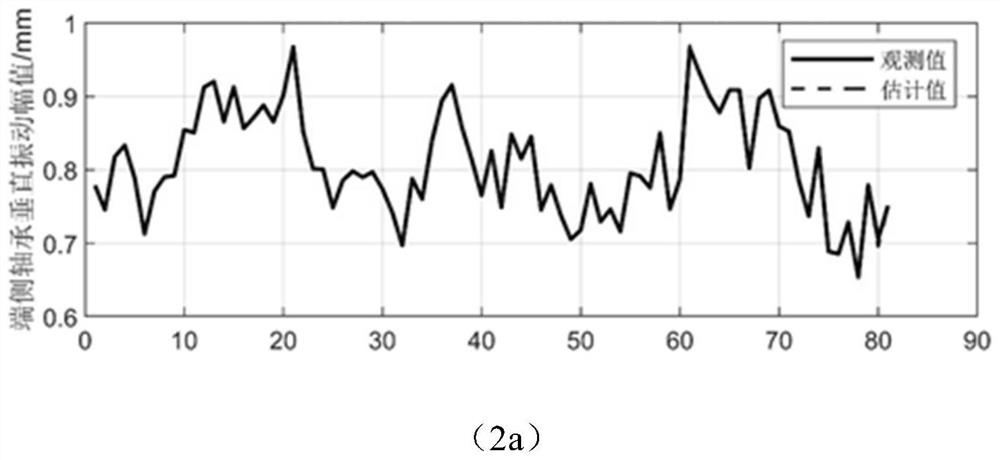

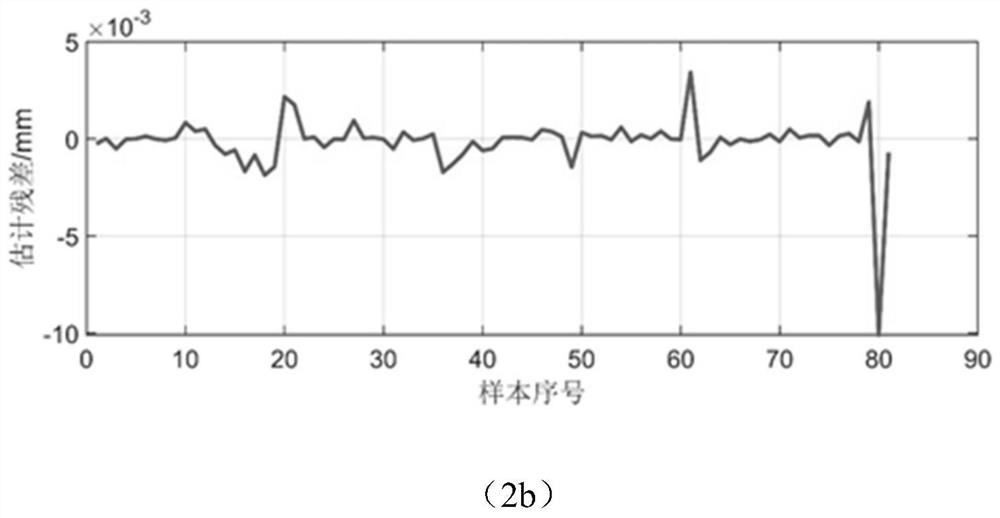

[0069] from figure 1 It can be seen from the figure that the estimated residual error of the horizontal bearing vibration on the end side of the blower in normal operation is less than 0.005mm, and the relative residual error is less than 0.7%. from figure 2 It can be seen from the figure that the estimated residual error of the vertical bearing vibration on the end side of the blower under normal operating conditions is less than 0.004mm, and the relative residual error is less than 0.57%. from image 3 It can be seen that the estimated residual error of the end-side bearing temperature in normal operating state is less than 0.05°C, and the relative residual error is less than 0.09%. from Figure 4 It can be seen from the figure that the estimated residual error of the waist bearing temperature under normal operating conditions is less than 0.05°C, and the relative residual error is less than 0.09%. The above results show that the estimated residual error and relative r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com