Test method for researching shear slip mechanical properties of frozen soil between freezing pipe curtain pipes

A technology of mechanical properties and test methods, applied in the direction of using stable shear force to test the strength, strength properties, scientific instruments, etc. Data-accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

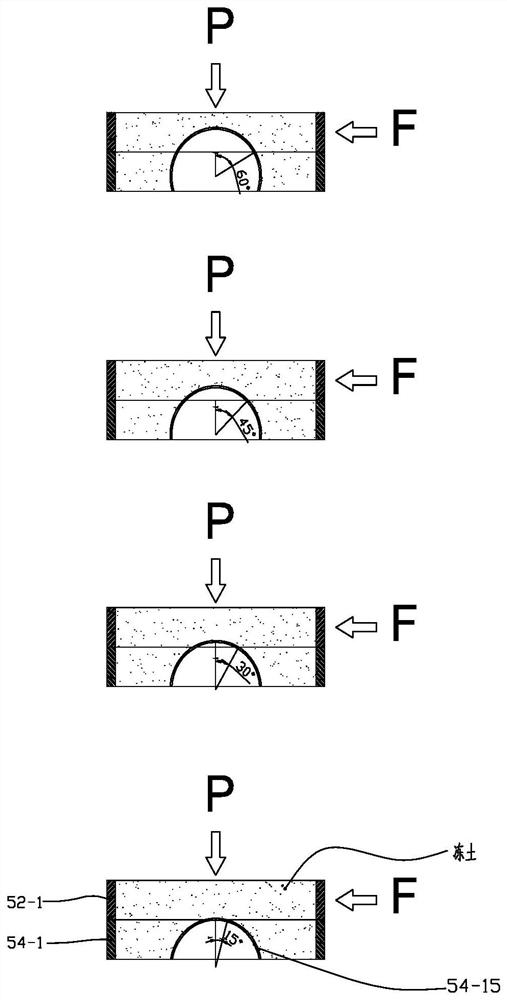

[0068] The test method for studying the mechanical properties of shear slippage of frozen soil between frozen pipe curtains includes the following steps, such as figure 1 Shown:

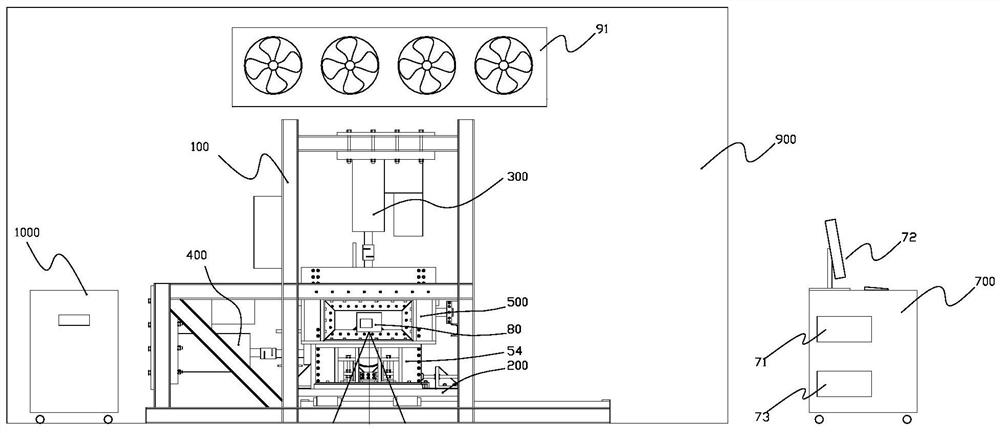

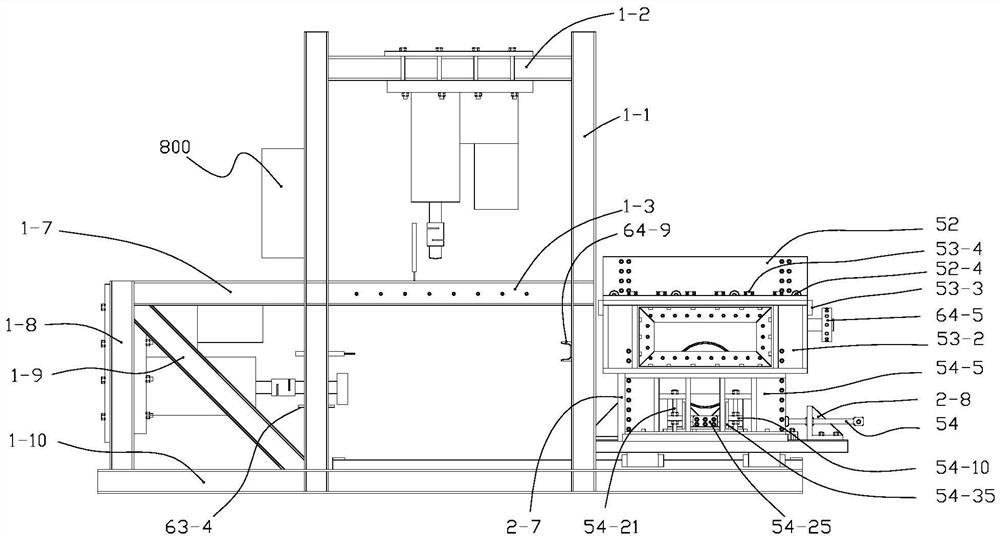

[0069] (A) Before the test starts, in the low temperature environment test room 900, assemble the reaction force frame assembly 100, the sliding assembly 200 and the driving loading unit, and the sliding assembly 200 and the driving loading unit are installed on the reaction force frame assembly 100; 900 is the room temperature state,

[0070] (B) Utilize the hoisting tool to hoist the shearing unit 500 and fix it on the sliding assembly 200, and fill the soil for the test into the shearing soil box surrounded by the shearing unit 500, and compact it according to the designed density, until the design soil thickness is reached; and push the shear working unit 500 filled with test soil into the main frame shear work area, and make it fully contact with the reaction frame assembly 100;

[0071] (C) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com