Automatic detecting and recycling system for farmland residue plastic films

An automatic detection and recycling system technology, applied in the agricultural field, can solve the problems of affecting agricultural production efficiency, damage to the agricultural environment, and low recycling efficiency, and achieve the effect of being suitable for popularization, improving flexibility and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following embodiments can make those skilled in the art understand the present invention more comprehensively, but do not limit the present invention to the scope of the described embodiments.

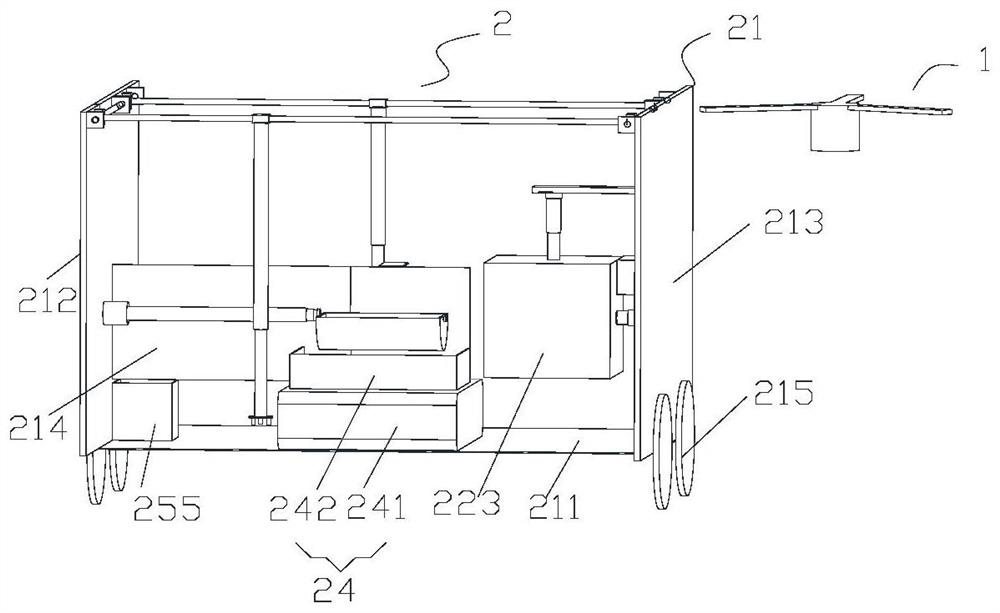

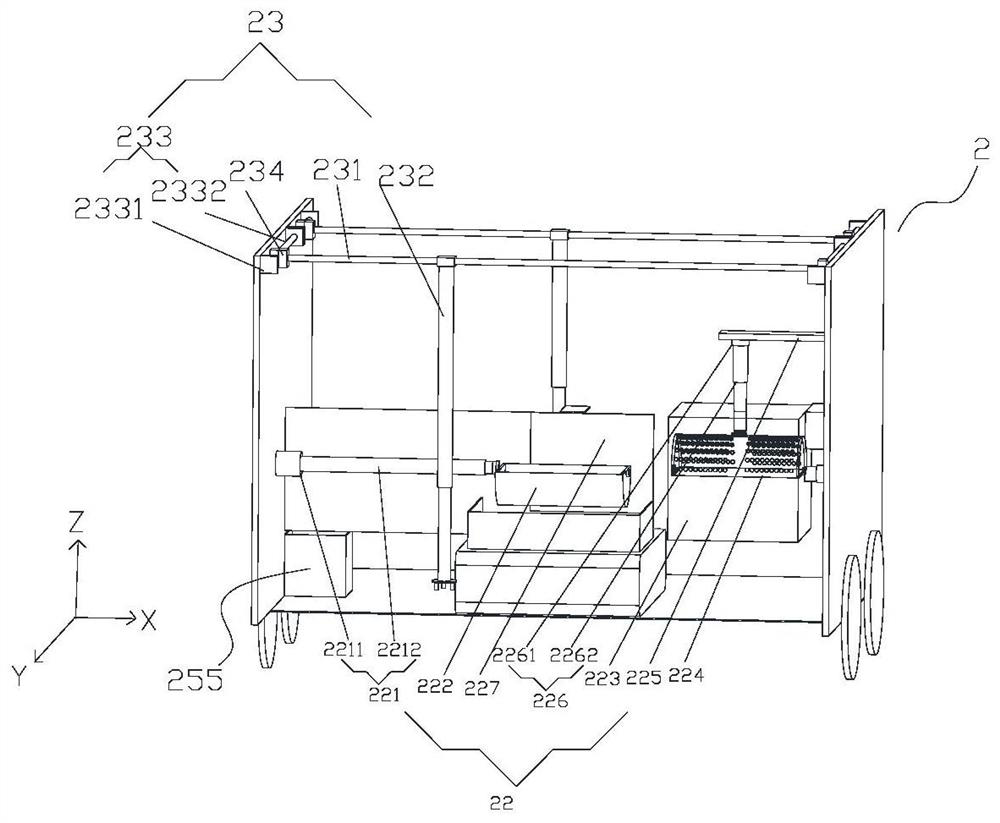

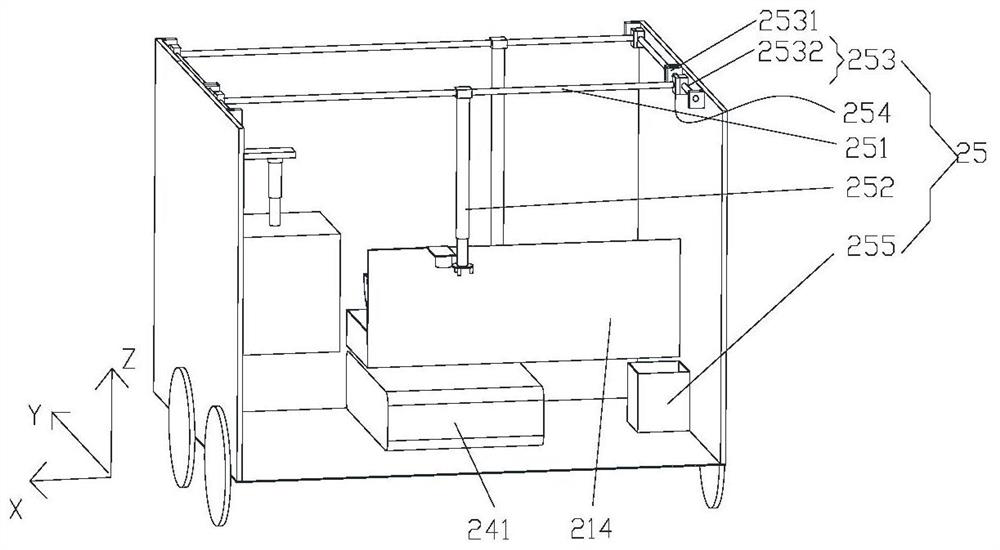

[0035] Please refer to figure 1 , The present invention provides an automatic detection and recovery system of farmland residual mold, including: a control device, a moisture detection device 1 and a residual film recovery device 2 . Wherein, the moisture detection device 1 is used to detect the moisture content of the soil in the watered field according to the preset trajectory, and determine the residual film existing point in the field according to the soil moisture content, and then send the position information of the residual film existence point to the control device. The control device is electrically connected with the residual film recovery device 2, and is used for controlling the operation of the residual film recovery device 2 according to the received position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com