Monitoring device and method for laser wet cleaning of carbon fiber resin matrix composites

A carbon fiber resin-based, composite material technology is applied in the field of laser cleaning to achieve the effect of reducing energy waste, simple and intuitive operation, and avoiding excessive cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

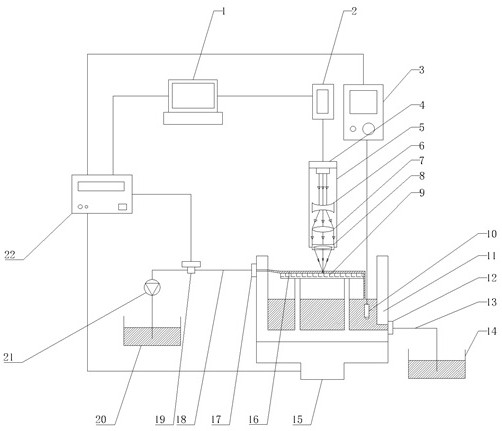

[0012] The device of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a monitoring device for laser wet cleaning of carbon fiber resin-based aviation composite materials, including a laser cleaning system, a control and detection system, and a water supply system. The laser cleaning system is composed of a laser, a lens cabin, a laser controller, a lens, and a host computer. The center of laser device 4 and concave lens 6, convex lens 7 and lens 8 in the lens group is located on the same straight line. The lens group diffuses the laser beam with parameters adjusted by the host computer 1 and the laser controller 2 to increase the coverage area, and then passes through the concave lens 6, the convex lens 7, and the lens 8, and then focuses it into a spot arrangement that meets the requirements for cleaning the material surface, and acts on the laser beam to be treated. Clean the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com