Electromagnetic Stirring Device and Method for Secondary Cooling Zone of Slab Continuous Casting

An electromagnetic stirring and slab continuous casting technology, which is applied in the field of electromagnetic stirring devices, can solve problems such as low stirring magnetic field strength, achieve the effects of avoiding adverse effects, refining grains, and improving internal quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

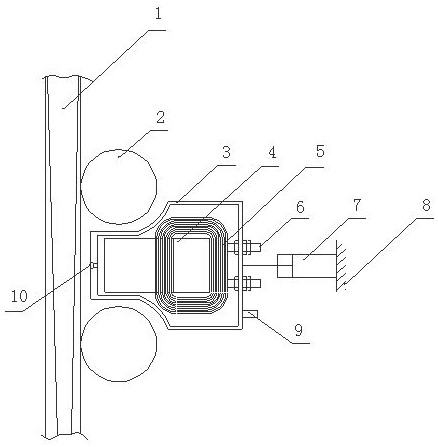

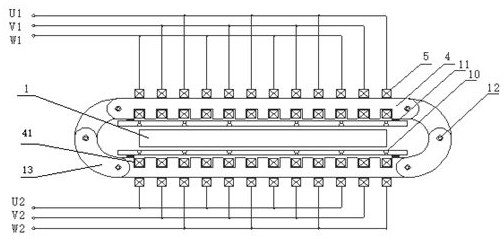

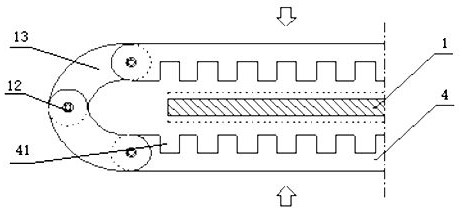

[0056] For high-speed continuous casting of thin slabs, the recommended electromagnetic stirring device is installed in the segment 0# of the caster segment near the outlet of the mold. Under the spray cooling effect of the cooling water nozzle in the secondary cooling zone, the thickness of the continuous casting slab shell at this time is about 10~20mm, the unsolidified fraction is 60~80%, and the solidified slab shell has enough strength to hold the casting slab 1 Internal molten steel, and adopt electromagnetic stirring on the outside of the wide side without worrying too much about the risk of steel leakage; moreover, the liquid core has a large uncondensed fraction, sufficient molten steel, and the growth of columnar crystals has just begun, which is just suitable for the secondary cooling zone Apply electromagnetic stirring with a certain intensity. The stirring current intensity is 800A, and the liquid core of the slab 1 forms a horizontal circular flow under the alter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com