An electromagnetic feeding control method for large-section slab continuous casting

A control method and large-section technology, applied in the field of continuous casting, can solve the problems of difficulty in replenishing the solidification shrinkage of liquid metal, difficult to control the solidification process of the slab, and central shrinkage, so as to improve the final solidification feeding effect and increase the fluidity. , to promote the effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

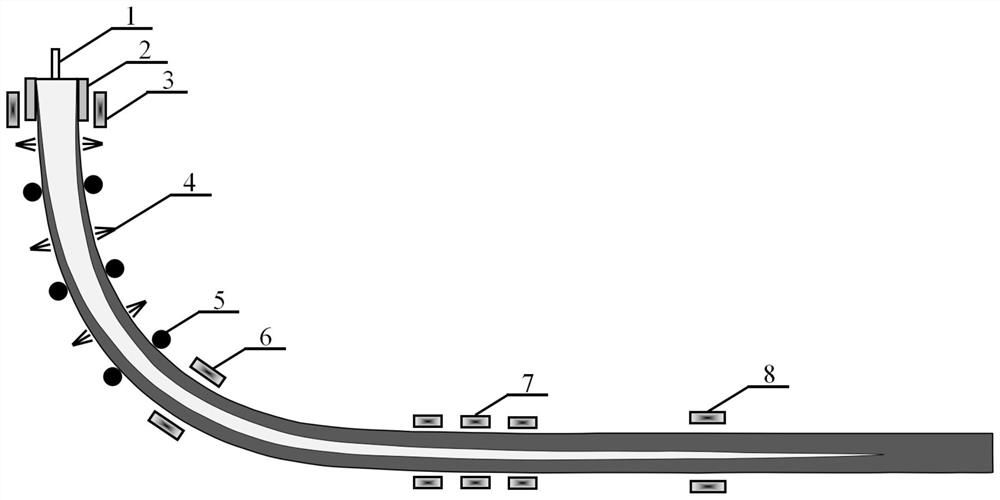

[0017] According to the electromagnetic feeding control method of the large-section slab continuous casting process of the present invention, the continuous casting machine is equipped with a terminal electromagnetic stirring device 8 at the end, and an electromagnetic heating device 7 is installed upstream of the terminal electromagnetic stirring device 8; the electromagnetic heating device The specific installation position of 7 corresponds to the area where the thickness of the solidified layer of the slab is 20% to 75% of the equivalent diameter. The electromagnetic heating device forms an alternating magnetic field with a frequency of 350 to 2500 Hz in the corresponding electromagnetic heating area. The Joule heat generated within the penetration depth of the surface layer of the slab increases the fluidity of the molten metal in the final sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com