Method for capturing continuous casting inclusion and novel submersed nozzle

An inclusion and immersion technology, which is used in casting melt containers, casting equipment, manufacturing tools, etc., can solve the problems of insufficient consideration and consideration of the ability of immersion nozzles to adhere and remove inclusions, so as to improve the melting ability, The effect of preventing slag entrainment and improving the quality of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

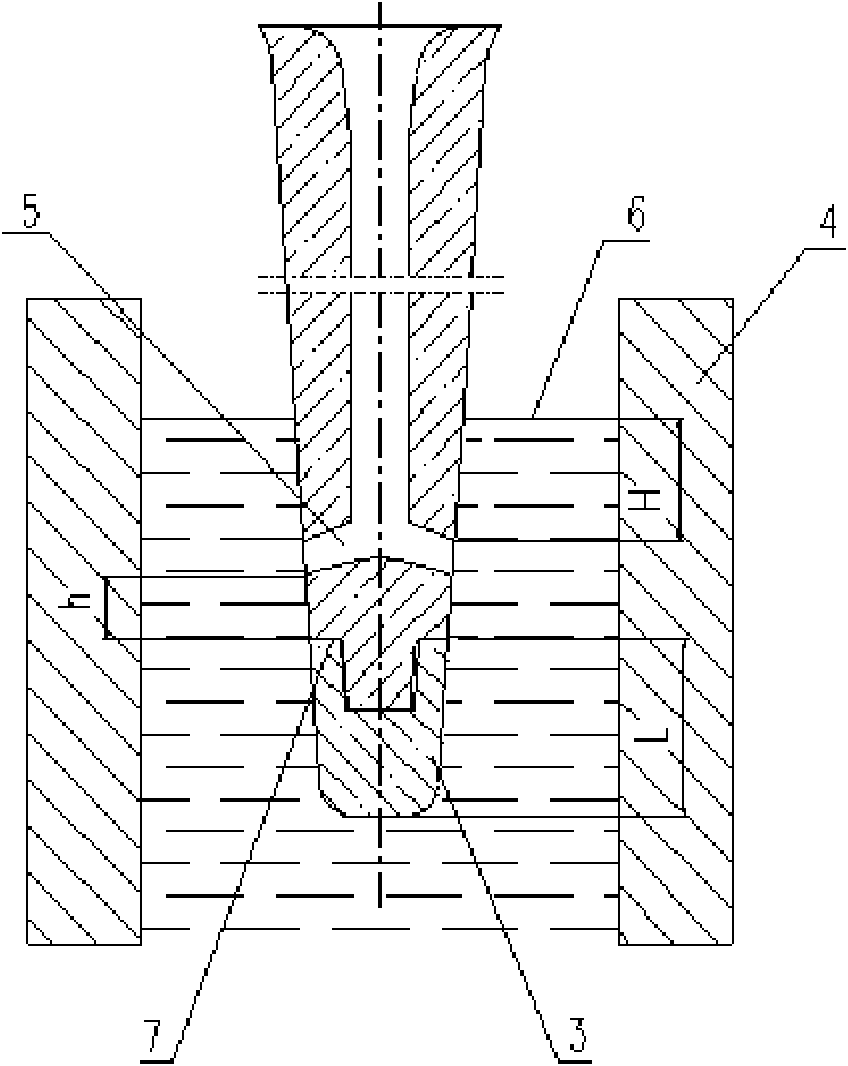

[0056] The present invention will be further described below according to accompanying drawing.

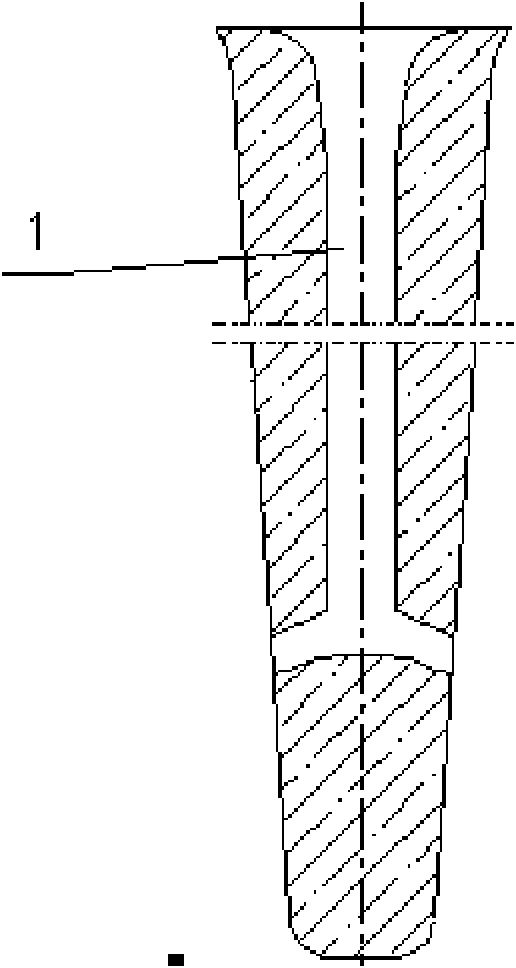

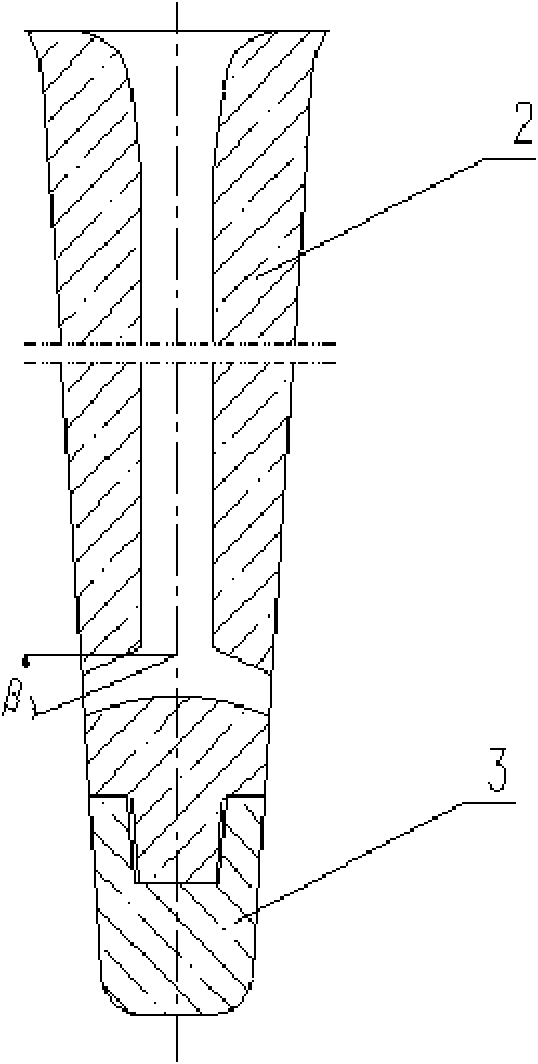

[0057] Such as figure 1 As shown, the submerged nozzle 1 with the function of capturing inclusions of the present invention is composed of upper and lower parts, the upper part 2 of the nozzle is a submerged nozzle with conventional functions; the lower part 3 of the nozzle is a part longer than the conventional submerged nozzle , is an inclusion trapping device; the upper part of the nozzle 2 and the lower part of the nozzle 3 are closely connected. When in use, the submerged nozzle is inserted into the molten steel in the mold 4, and the molten steel in the mold 4 rotates under the action of the electromagnetic stirring of the mold, and the inclusions in the molten steel will accumulate toward the center and be mixed with the lower part 3 of the nozzle. The inclusion capture device collides with it, is captured by it, and adheres to the surface of the inclusion capture device, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com