Pipeline rapid welding auxiliary device

A rapid welding and auxiliary device technology, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of large concentricity deviation of welded pipes, excessive concentricity deviation, and poor welding quality. Achieve the effect of ensuring the coaxiality of the pipeline, speeding up the welding speed and improving the welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the purpose, structure and function of the present invention, the understanding of the present invention will be given below in conjunction with the accompanying drawings.

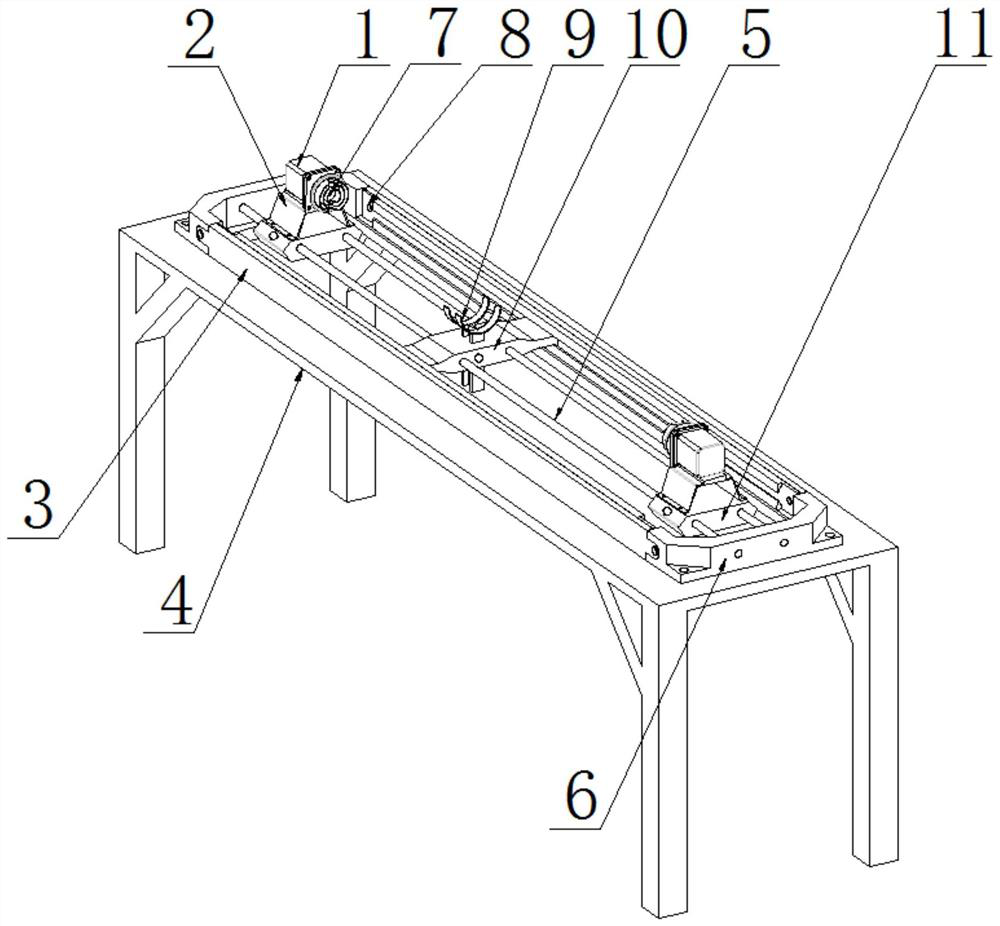

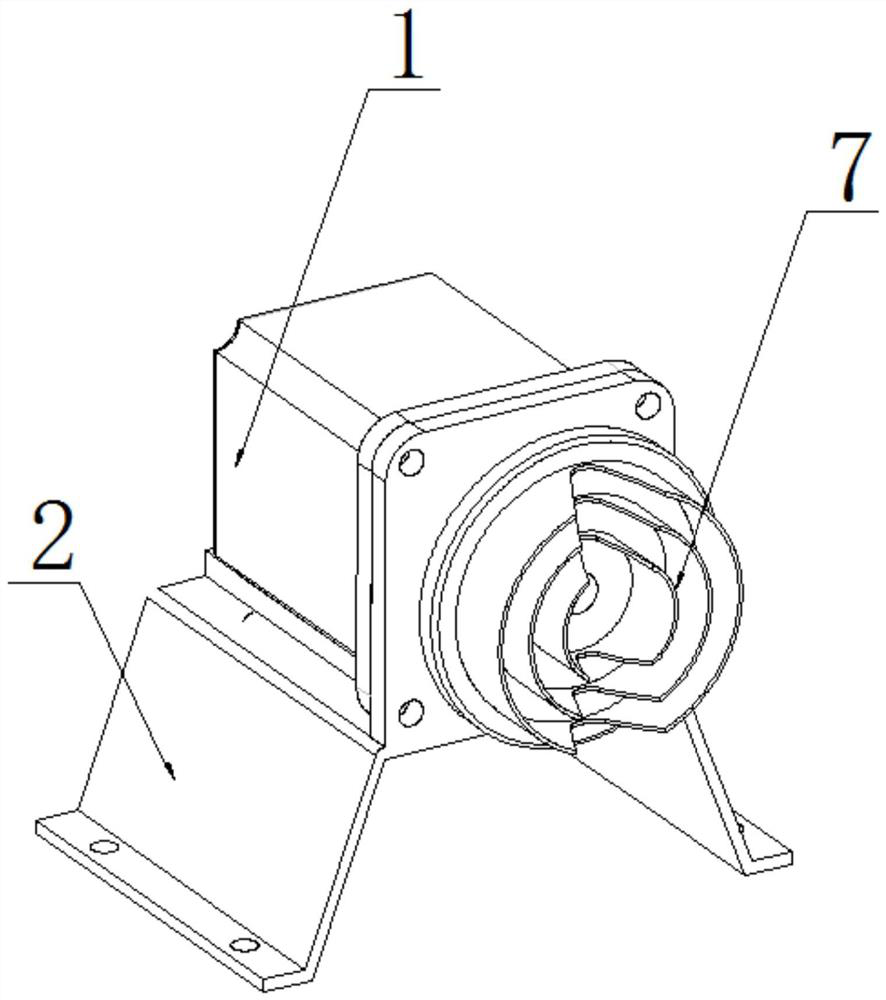

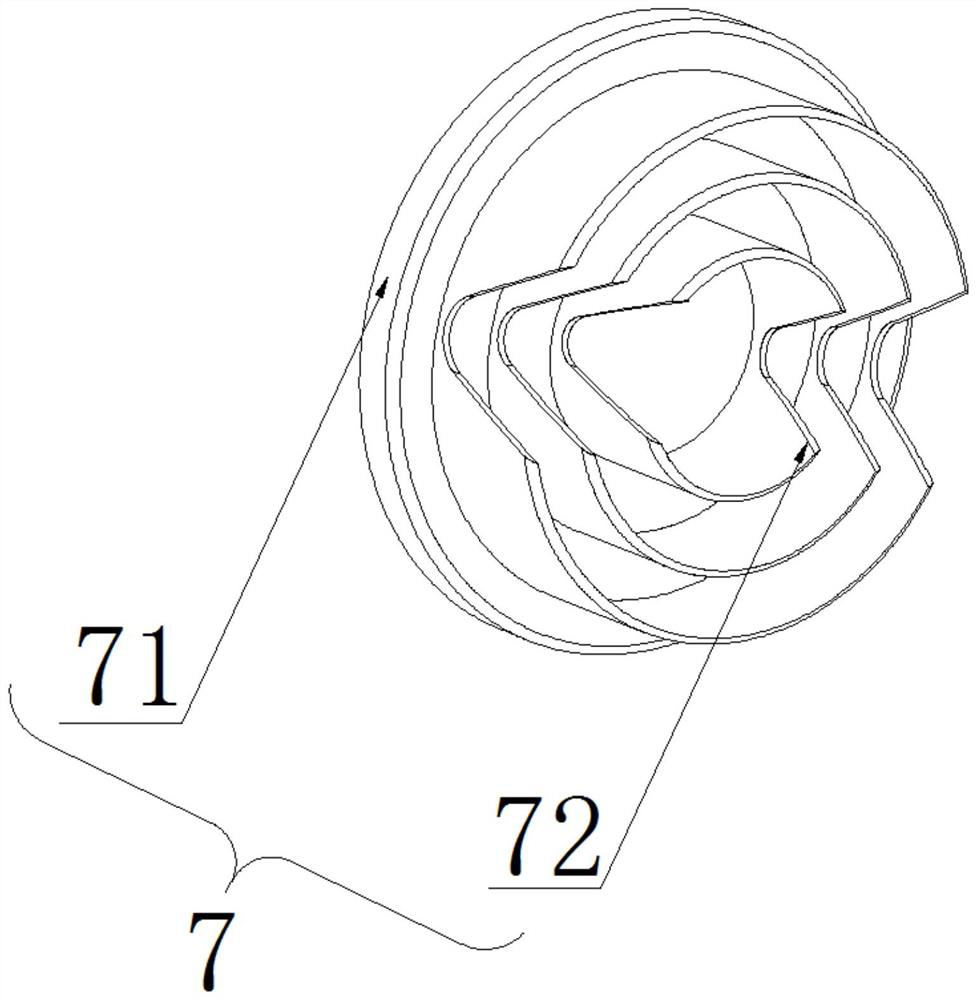

[0024] Such as Figure 1-3 , the device realizes fast welding of pipelines, ensures the concentricity of pipeline welding and preserves the welding skills of workers. The supporting components in the overall structure are two light rods 5 and two guide rails 8 respectively fixed by the end base 6 and the guide rail base 3, and the guide rail base 3 and the end base 6 are connected by screws. The guide rail base 3, the light rod 5, the end seat 6 and the guide rail 8 are all installed on the workbench 4. The light rods 5 are arranged in parallel, and each light rod 5 passes through the motor slider 11 and the support member 9 at the same time.

[0025] The light bar 5 is equipped with two motor sliders 11, the motor 1 is fixedly connected to the motor slider 11 through...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap