Polishing robot for engineering machinery construction

A technology of construction machinery and robots, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of wasting resources, difficult to clean, and difficult to clean debris, so as to reduce pollution, The effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

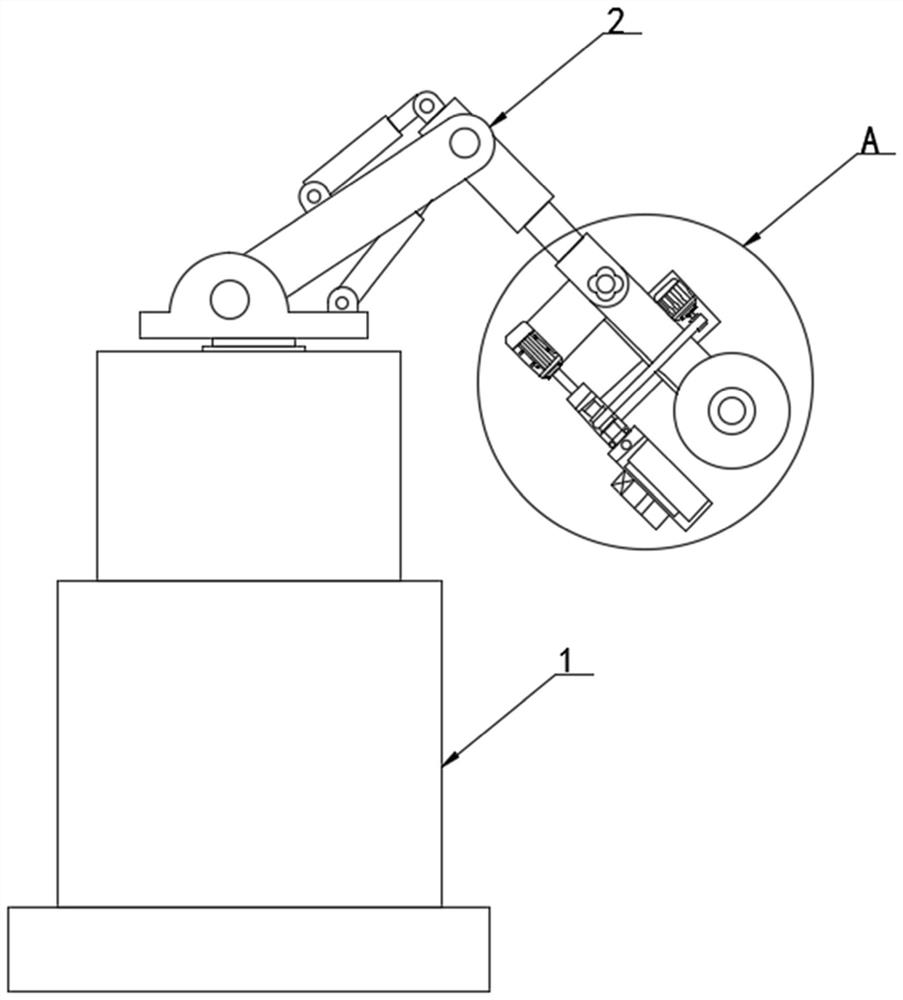

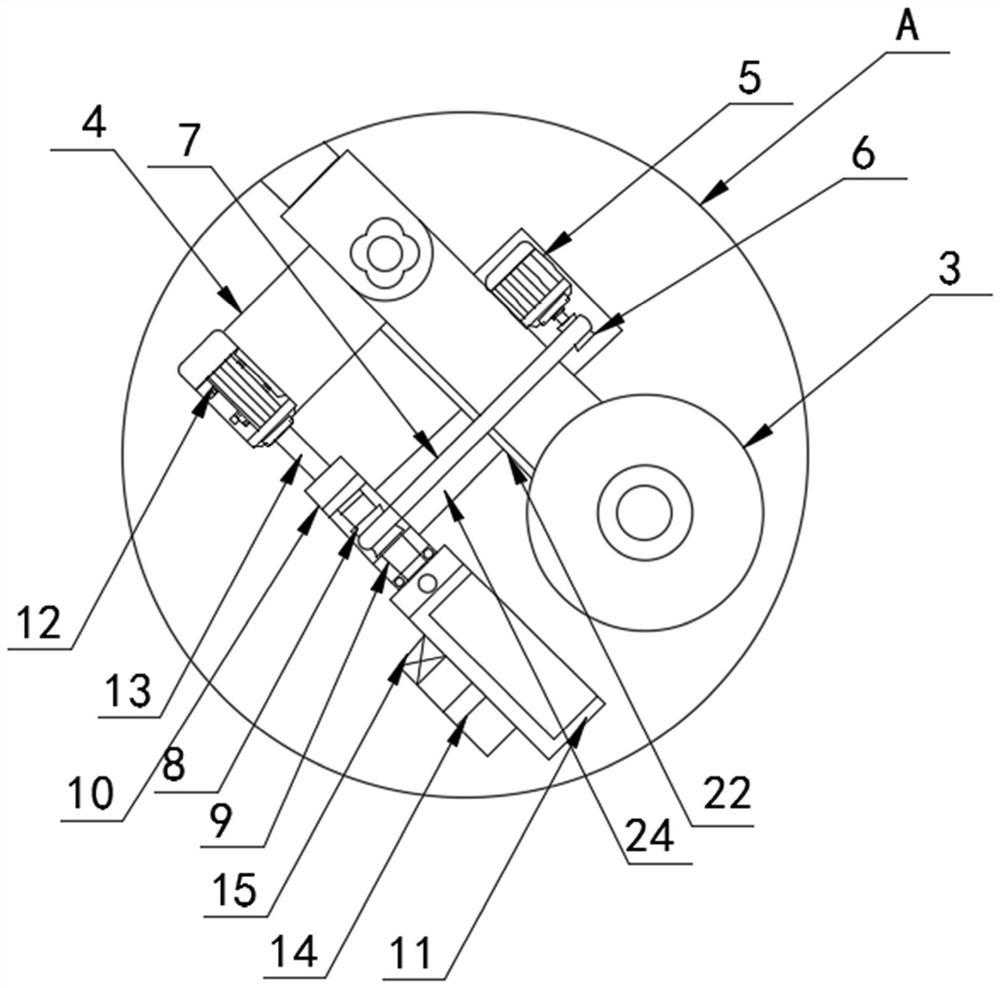

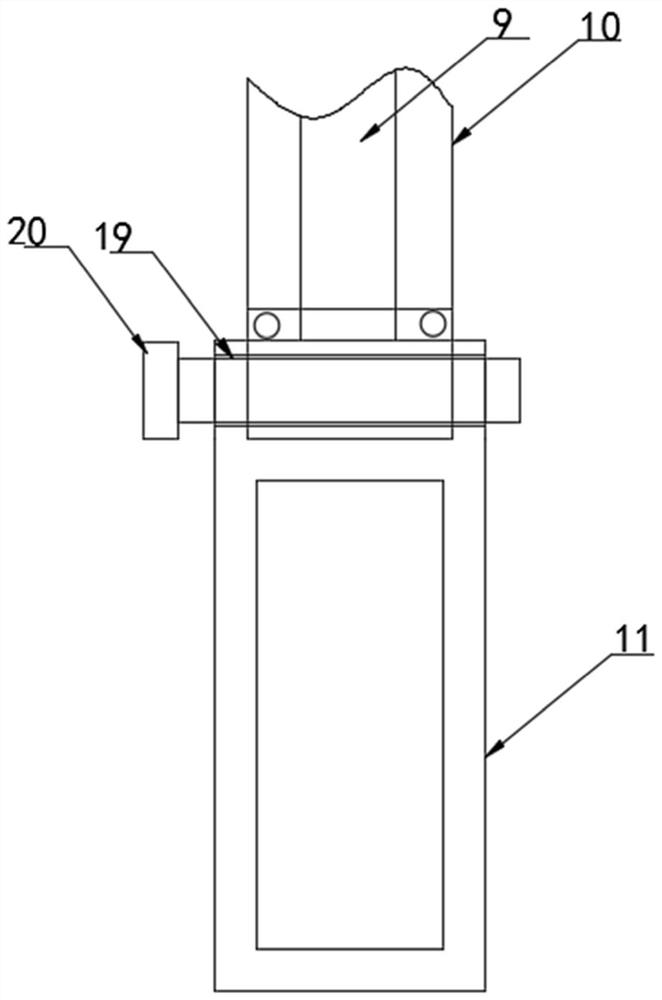

[0025] Refer to attached Figure 1-3 A polishing robot for engineering machinery construction provided by the present invention includes a polishing robot body 1, a first chip removal device 4, and a second chip removal device 21. A power arm 2 is installed on the top of the polishing robot body 1, and the power arm 2 A polishing disc 3 is installed at one end of the arm 2, a first chip removal device 4 is installed at the bottom of the power arm 2, a servo motor 5 is installed on the outer surface of the top of the power arm 2 of the first chip removal device 4, and the output end of the servo motor 5 is The first transmission plate 6 is installed, the outer surface of the first transmission plate 6 is socketed with the conveyor belt 7, one end of the conveyor belt 7 is socketed with the second transmission plate 8, one side of the transmission plate 8 is fixedly connected to the rotating shaft 9, and the rotation One end of the shaft 9 is provided with a chip storage box 11,...

Embodiment 2

[0031] Refer to attached Figure 4-5, a polishing robot for engineering machinery construction provided by the present invention includes a second chip removal device 21, an air pump 16, an air pipe 17 and a high-pressure air spray head 18. Specifically, the second chip removal device 21 is installed at the bottom of the power arm 2, and the second chip removal device 21 is installed at the bottom of the power arm 2. Air pump 16 is installed on the inner arm at the bottom of the second chip removal device 21. Air pipe 17 is installed at the output end of air pump 16. One end of air pipe 17 is fixedly connected to high-pressure air jet head 18. When the debris in the debris storage box 11 is full, the first servo motor can be started. 5. Drive the conveyor belt 7 through the first conveying plate 6 and the second conveying plate 8, turn the crumb storage box 11 to 90 degrees, make the opening of the crumb storage box 11 face down, cut off the power of the electromagnet 14, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com