High-precision wood contour cutting equipment for wood sculpture

A cutting equipment, high-precision technology, applied in the direction of sawing equipment, machine tools suitable for grinding workpiece edges, metal processing equipment, etc., can solve the problems of rough size, unfavorable engraving, etc., to ensure stability and edge flatness , Guarantee the effect of cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

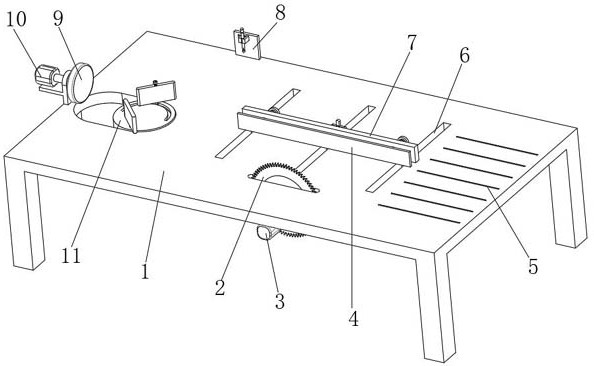

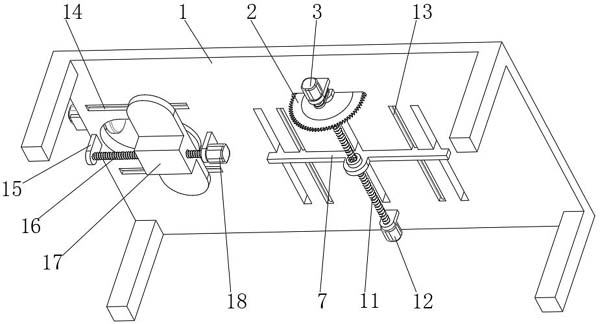

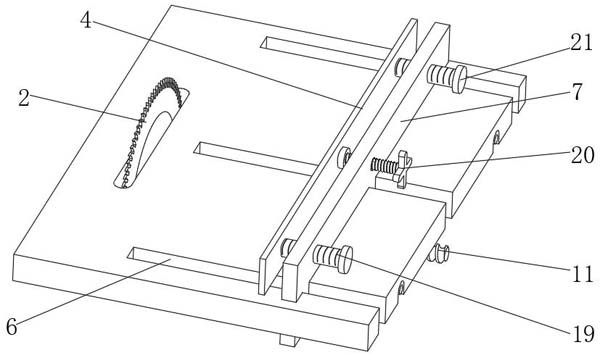

[0033] A high-precision wood contour cutting equipment for wood sculpture, such as Figure 1-6As shown, it includes a workbench 1, the outer wall of the bottom of the workbench 1 is equipped with a cutting mechanism through a bracket, and the cutting mechanism includes a cutting saw blade 2 and a cutting motor 3, and the cutting saw blade 2 is installed under the workbench 1 through a bracket, and The top of the cutting saw blade 2 runs through the inner wall of the workbench 1 and is higher than the top surface of the workbench 1; the cutting motor 3 is mounted on the bottom outer wall of the workbench 1 through a bracket, and the cutting saw blade 2 is connected to the output end of the cutting motor 3 through gear rotation; The top outer wall of the workbench 1 is equidistantly provided with three translation passages 6, the inner walls of the three translation passages 6 are slidingly connected with the same guide plate seat 7, the bottom outer wall of the guide plate seat ...

Embodiment 2

[0040] A high-precision wood contour cutting equipment for wood sculpture, such as figure 1 , figure 2 , Figure 6 As shown, in order to improve the functionality; this embodiment makes the following improvements on the basis of Embodiment 1: the outer wall of one side of the workbench 1 is equipped with a grinding motor 10 through a bracket, and the output end of the grinding motor 10 is rotationally connected through a coupling Grinding disc 9 is arranged, and grinding disc 9 is installed on the support of grinding motor 10 by bearing seat; By arranging grinding disc 9 and grinding motor 10, work such as grinding angle can be carried out to the timber that has cut, provides convenience for follow-up engraving work.

[0041] Improve the convenience of use; such as figure 1 , figure 2 , Figure 6 As shown, the inner wall of the workbench 1 is slidingly connected with a grinding seat 11, the outer wall of the bottom of the grinding seat 11 is installed on the workbench 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com