High-precision attitude adjustment equipment for thin-wall cabin of large spacecraft

A spacecraft and high-precision technology, which is applied to ground devices, aircraft assembly, transportation and packaging, etc., can solve the problems of weak rigid structure, insufficient scalability, and low versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

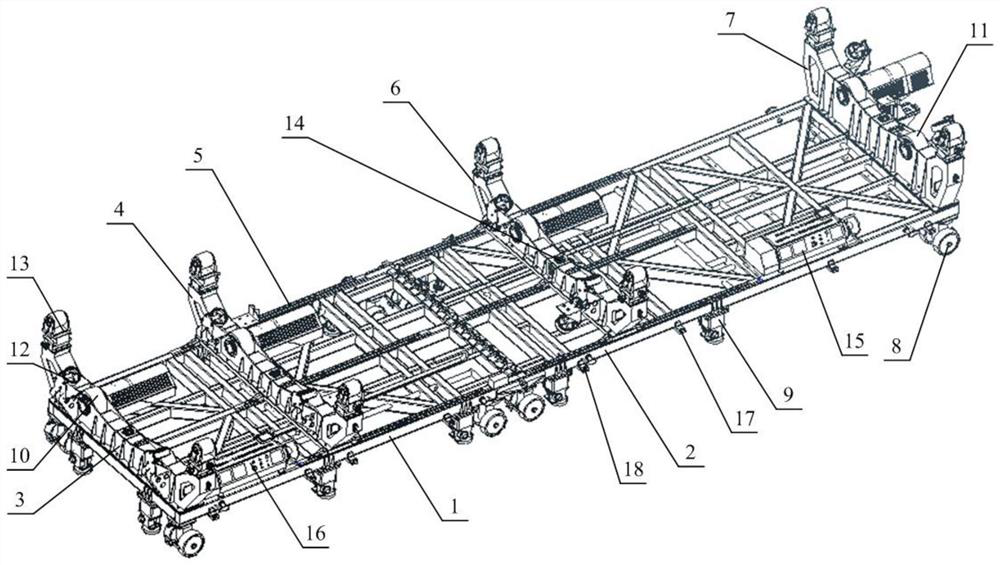

[0036] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

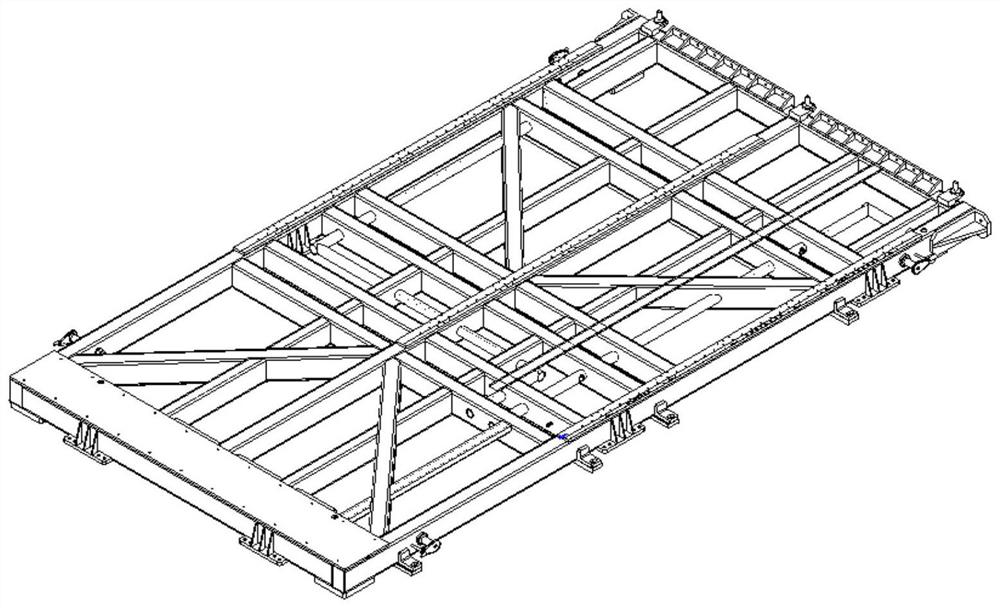

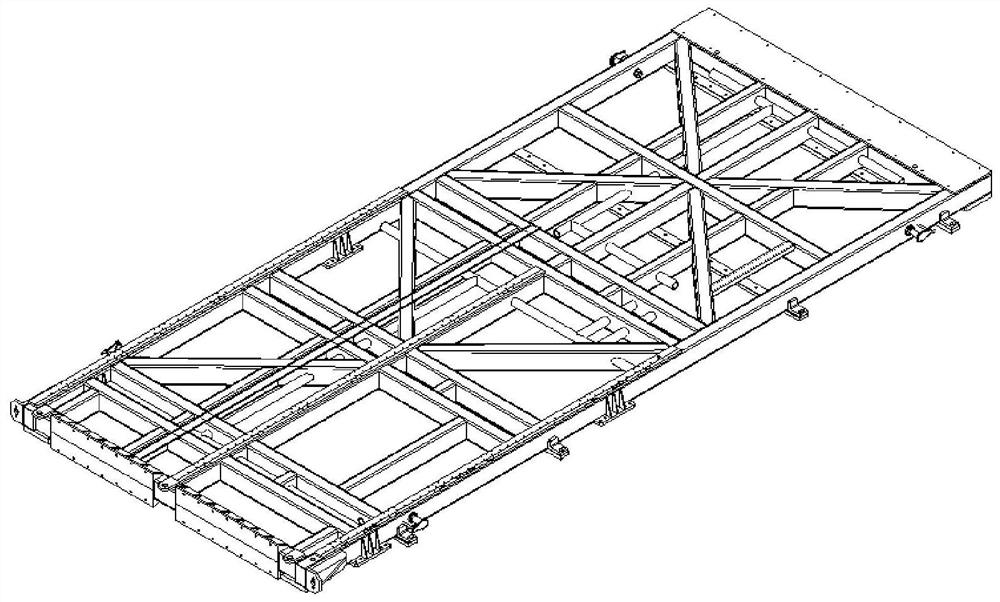

[0037] like figure 1 As shown, the present invention provides a kind of high-precision attitude adjustment equipment for thin-walled cabins of large spacecraft, which includes a first cabin platform 1, a second cabin platform 2, a first fixed bracket assembly 3, a first Two moving bracket components 4, guide rail slider components 5, third moving bracket components 6, fourth fixed bracket components 7, universal casters 8, adjusting legs 9, active actuators 10, follow-up actuators 11, Axial limit mechanism 12, auxiliary support device 13, position feedback assembly 14, first control system 15, second control system 16, transfer structure 17, hoisting structure 18; wherein,

[0038] The first cabin platform 1 is respectively equipped with a first fixed bracket ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com