Double-sided needle cylinder fabric tension balancing structure of circular knitting machine

A balanced structure, knitting machine technology, applied in weft knitting, weft knitting circular knitting machines with separate action needles, knitting, etc. Uniformity and other issues, to achieve the effect of large pulling force, large free space, and uniform force points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now, the invention will be further explained with reference to the attached drawings and specific embodiments.

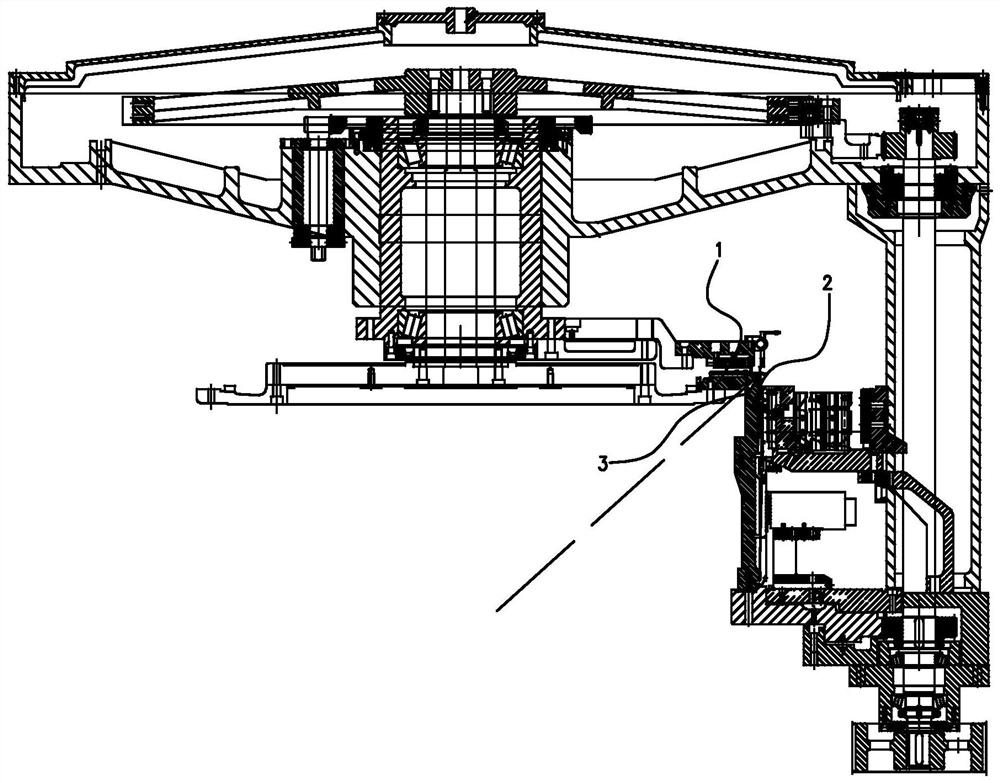

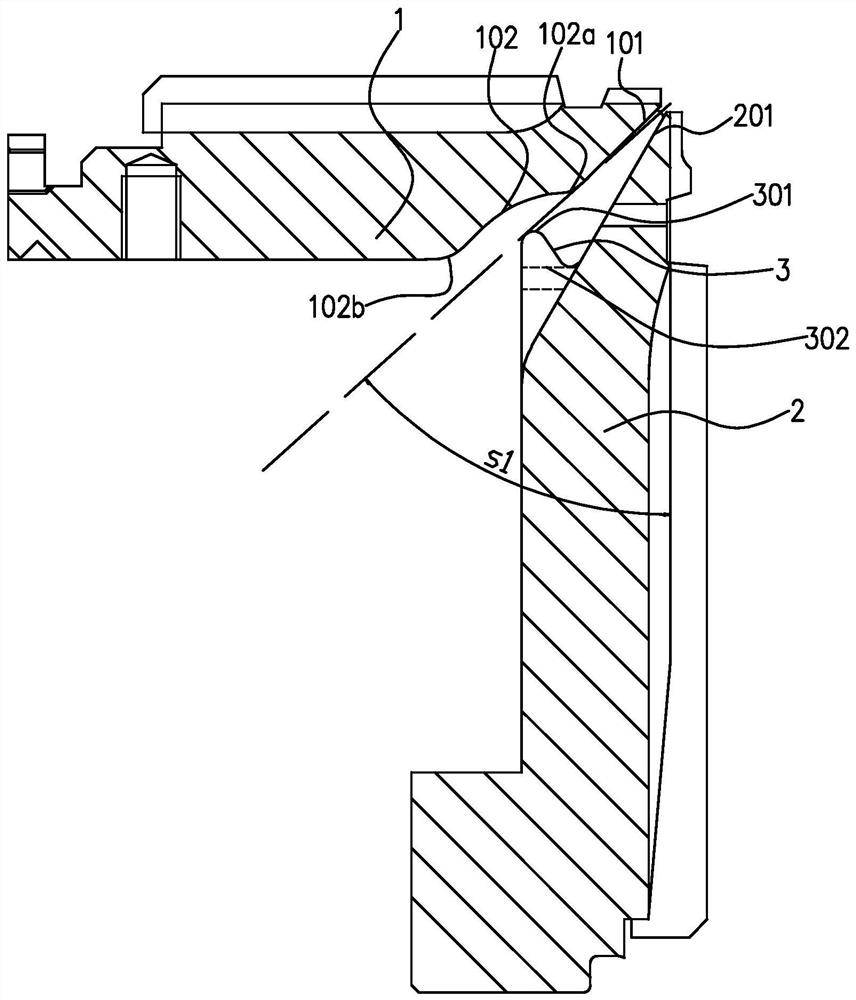

[0026] refer to 1 to 2This embodiment provides a tension balance structure of double-sided needle cylinder fabric of circular knitting machine, which comprises an upper needle cylinder 1 and a lower needle cylinder 2, wherein the outer side of the upper needle cylinder 1 is provided with a second inclined plane 101, the upper needle cylinder 1 is located above the lower needle cylinder 2, the needle mounting surfaces of the upper needle cylinder 1 and the lower needle cylinder 2 are closely matched, and there is a distance between the upper needle cylinder 1 and the lower needle cylinder 2, preferably vertical or other angle matching, and the lower needle cylinder 2 is circular. The top of the lower needle cylinder 2 is provided with a first inclined plane 201, which inclines from outside to inside and from top to bottom. There is a cloth conveying channel betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com